Automatic cosmetic lotion bottle

A technology for cosmetics and lotion bottles, which is applied to bottles, bottle/can parts, rigid containers, etc. It can solve problems such as inability to dump, waste, and trouble, and achieve the effects of convenient discharge, reduced adhesion, and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

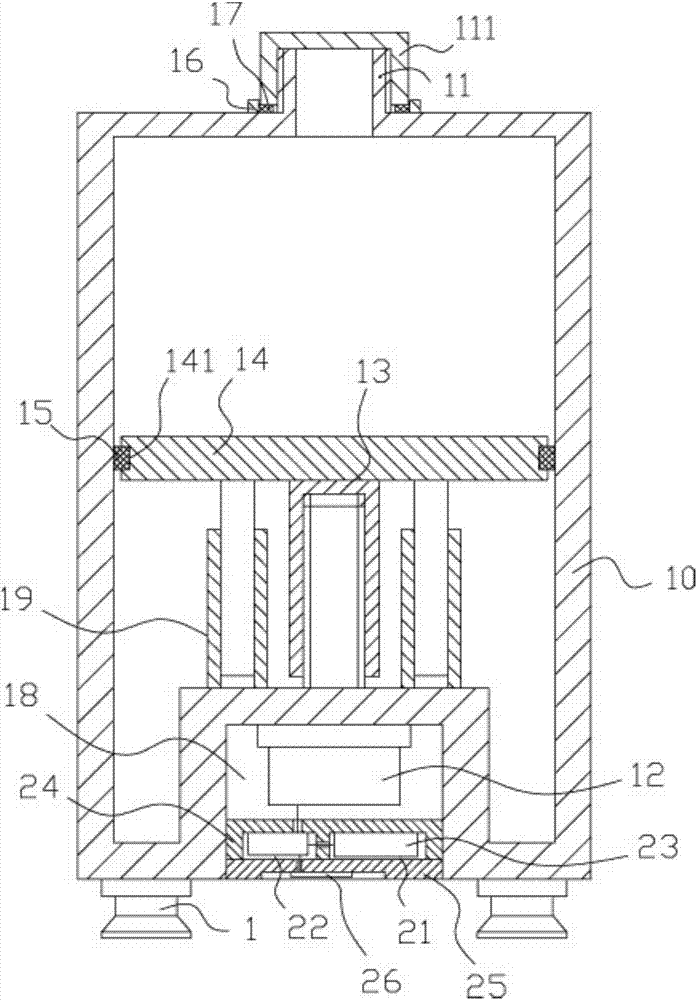

[0020] Example: see Figure 1 to Figure 2 As shown, a kind of automatic cosmetic lotion bottle, comprises main bottle body 10, and the top surface middle part of described main bottle body 10 has the liquid outlet screw joint 11 that extends upwards, and the bottom plate middle part of main bottle body 10 is fixed with lifting motor 12, lifts The output shaft of motor 12 stretches out the bottom plate of main bottle body 10 and is screwed with lifting screw sleeve 13, and the top of lifting screw sleeve 13 is fixed on the bottom surface middle part of lifting plate 14, and the outer side wall of lifting plate 14 has annular groove 141, sealing The ring 15 is nested in the annular groove 141, and the outer wall of the sealing ring 15 elastically presses against the inner wall of the main bottle body 10;

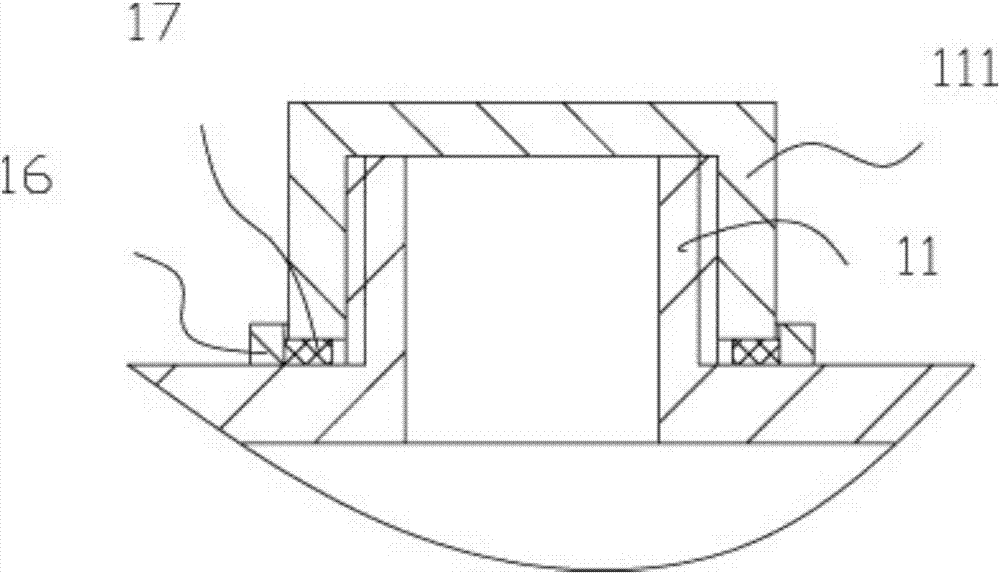

[0021] A bottle cap 111 is screwed on the outlet screw joint 11;

[0022] The top surface of the main bottle body 10 is formed with an annular positioning raised ring 16, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com