Raw material grinding device for chemical product research and development

A technology for chemical products and grinding devices, applied in the chemical field, can solve the problem of not having easy discharge, and achieve the effect of improving grinding effect and easy discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

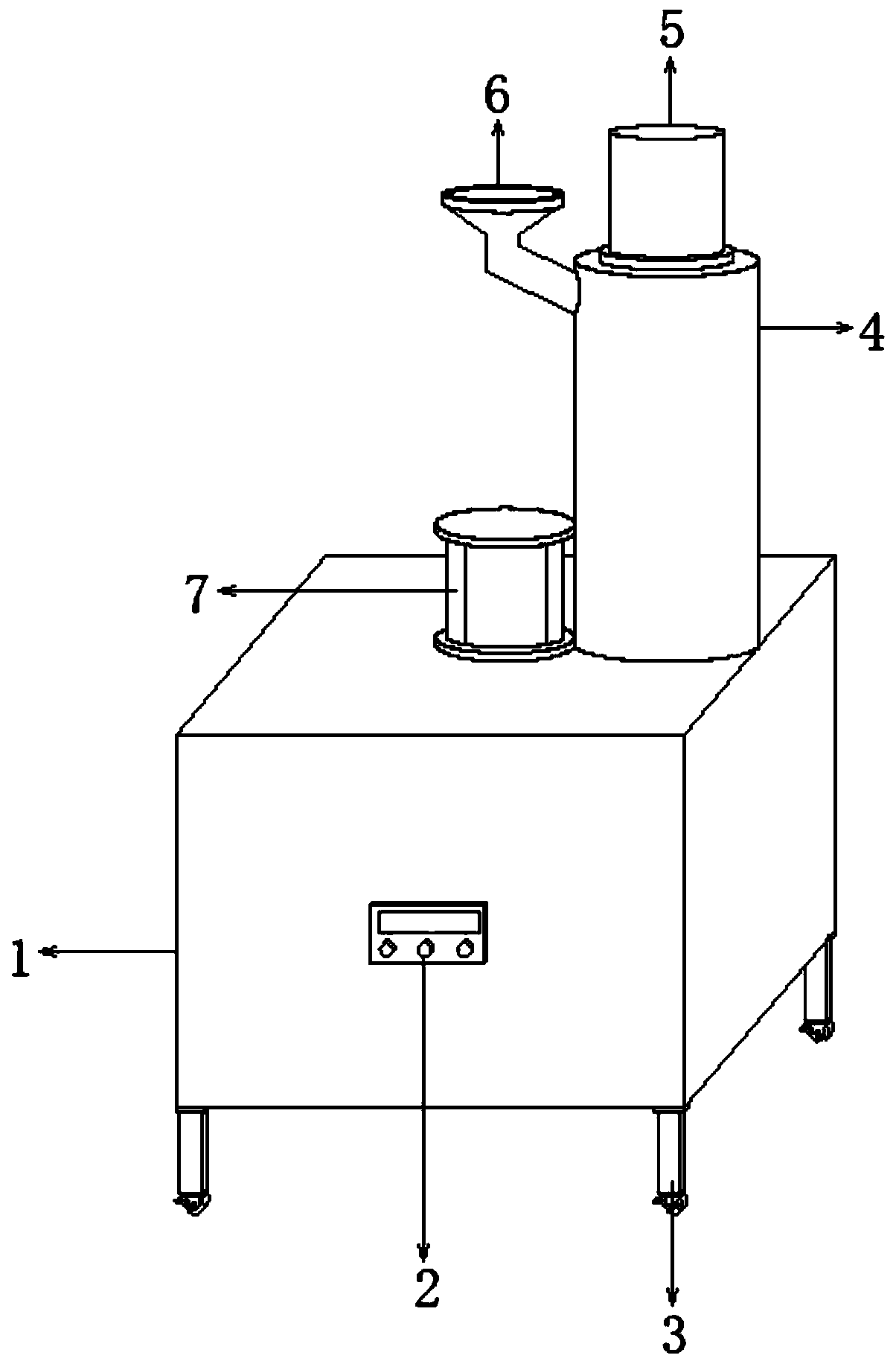

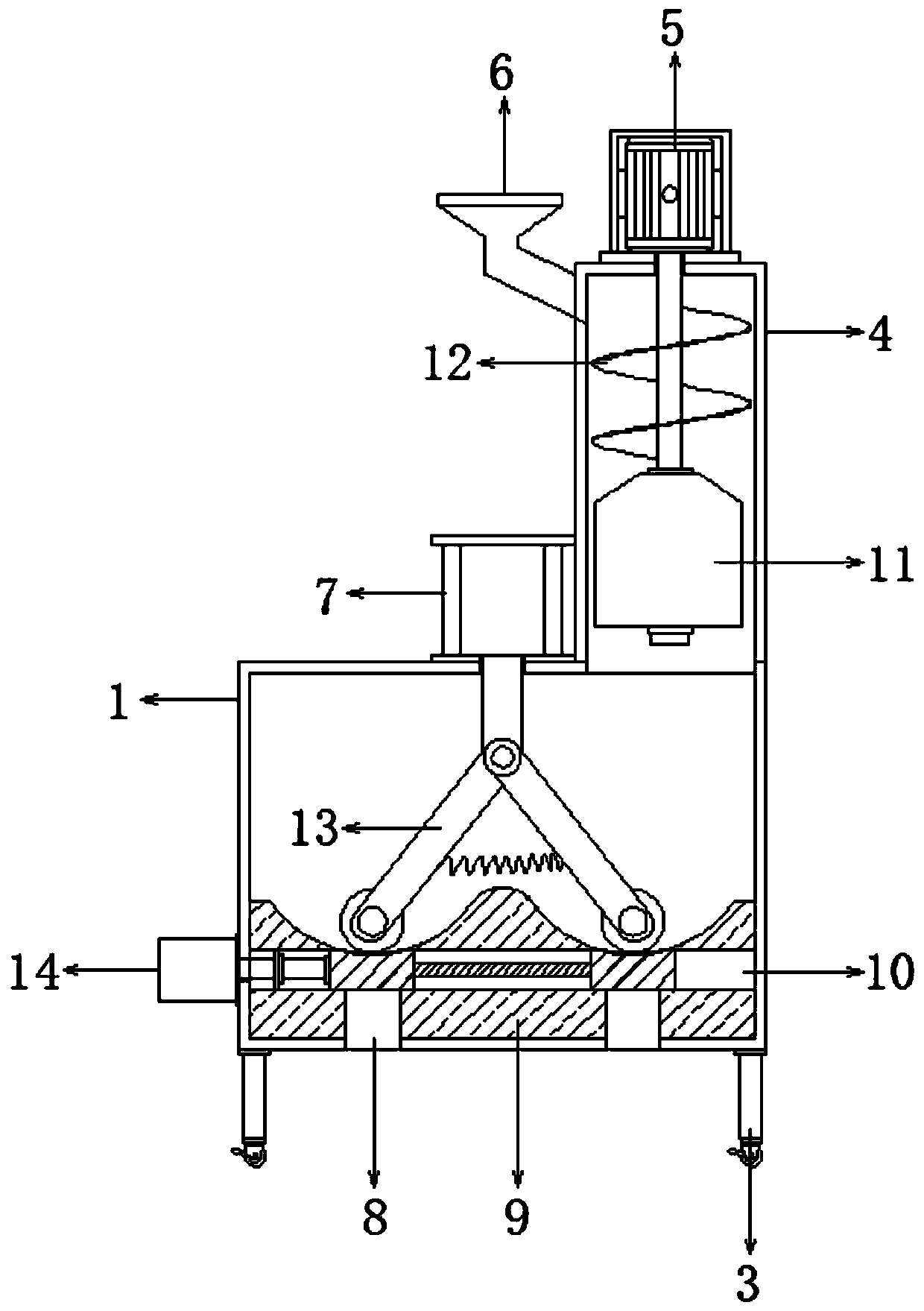

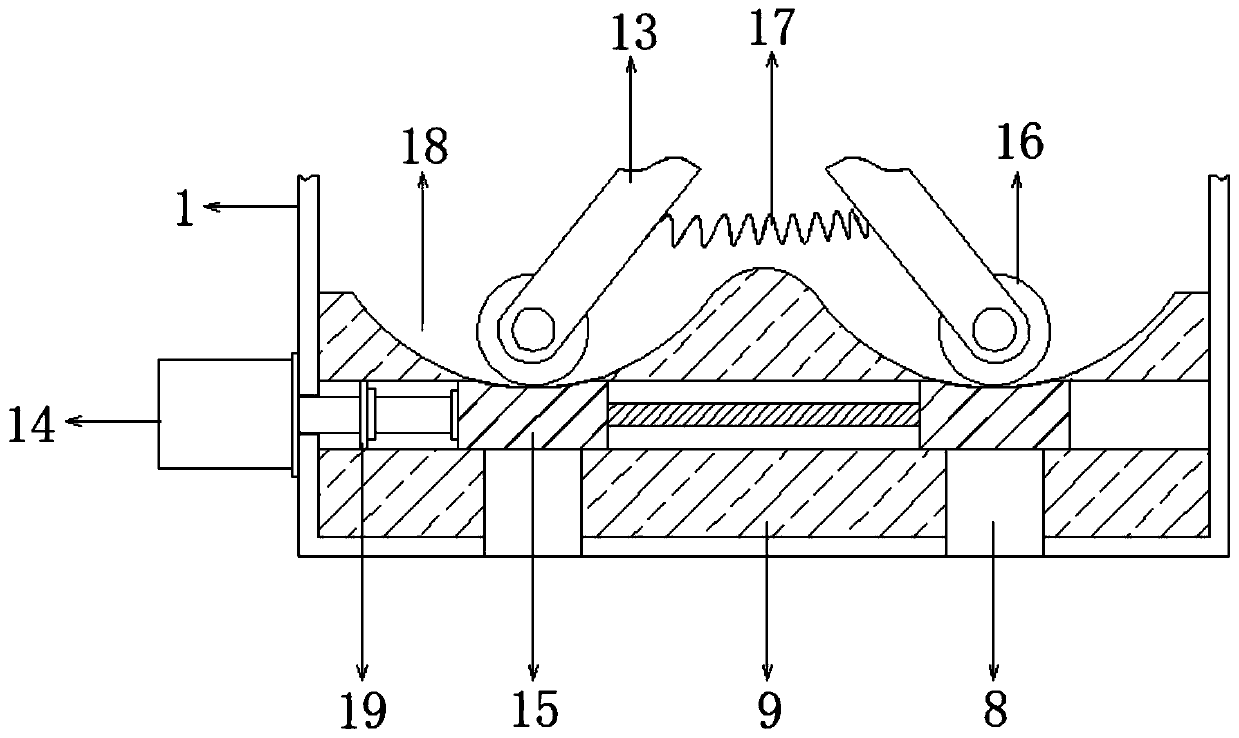

[0027] refer to Figure 1-3 , a raw material grinding device for research and development of chemical products, comprising a grinding box 1, a grinding cylinder 4 is connected to one side of the top of the grinding box 1 through bolts, and a feeding hopper 6 is connected to the top of one side of the grinding cylinder 4 through bolts, and the grinding cylinder There is a material guide port between the bottom of 4 and the top of the grinding box 1, and the bottom of the grinding box 1 is connected with a grinding seat 9 by bolts, and both sides of the top of the grinding seat 9 are provided with arc-shaped grinding grooves 18, arc-shaped The middle position of the bottom of the grinding tank 18 is provided with a discharge hole 8 extending out of the grinding box 1, and the inner middle position of the grinding seat 9 is provided with a transverse groove 10, and the outer wall of the side of the grinding box 1 near the transverse groove 10 is connected by bolts. Electric push ...

Embodiment 2

[0035] refer to Figure 4 , a raw material grinding device for research and development of chemical products. Compared with Embodiment 1, this embodiment has a vibrating motor 20 connected to the middle of the bottom outer wall of the grinding box 1 by bolts.

[0036] Working principle: When discharging, the vibration motor 20 is used to drive the whole device to vibrate, so that the device is completely discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com