Cleaning device for traditional Chinese medicinal material production and processing

A cleaning device and a technology of Chinese herbal medicines, applied in liquid cleaning methods, lighting and heating equipment, cleaning methods and utensils, etc., can solve the problems of taking a long time to dry naturally, not good enough effect, and inconvenient cleaning, etc. Achieve the effect of avoiding the deterioration of water absorption effect, good cleaning effect and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

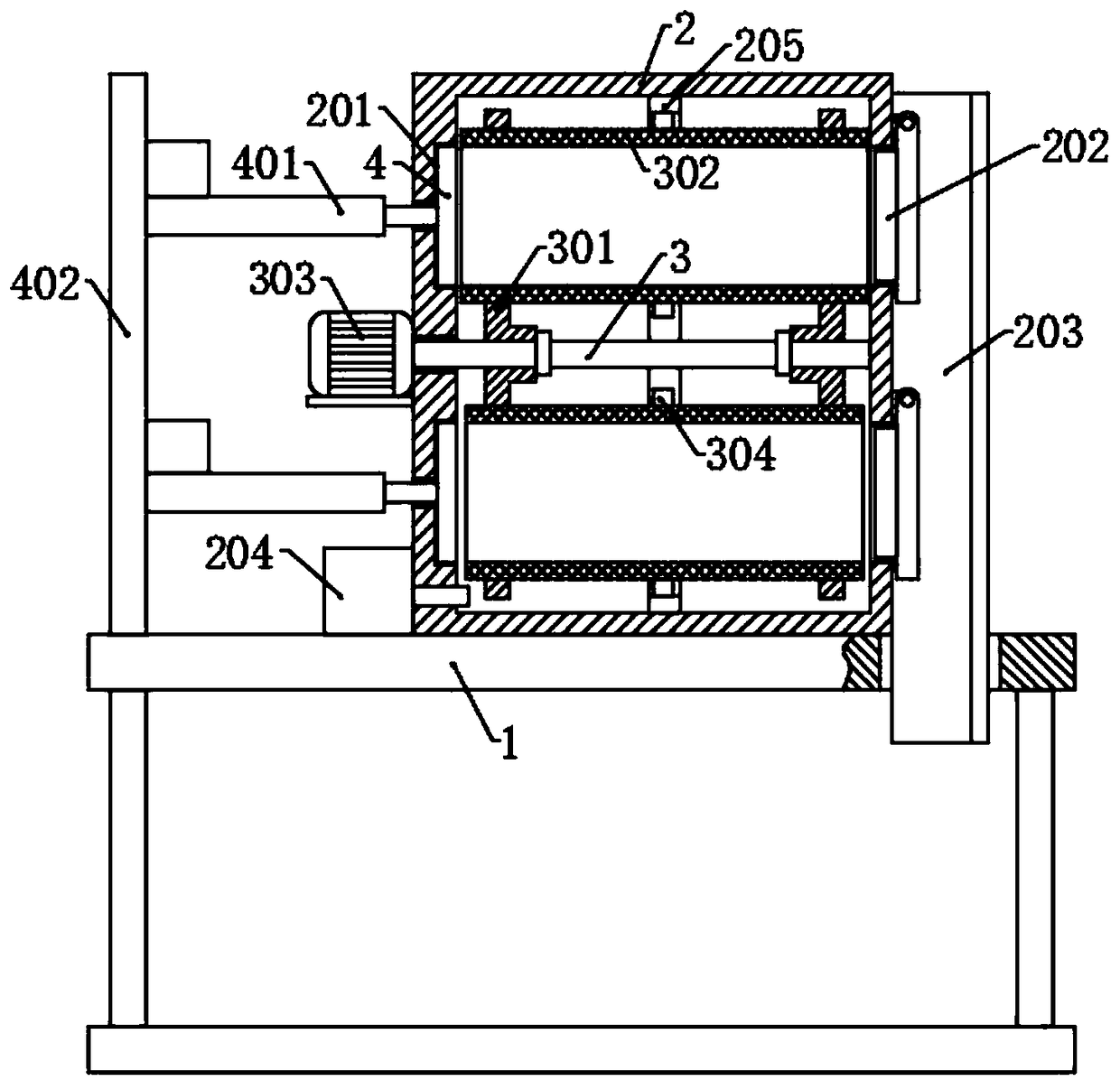

[0031] Please refer to the accompanying drawings, the present invention provides a technical solution: a cleaning device for the production and processing of Chinese medicinal materials, including a support frame 1, a cleaning box 2 and a pushing mechanism, the support frame 1 includes a bottom plate and a top plate, and the bottom plate and the top plate are fixedly connected There is a support rod, and the cleaning box 2 is positioned at the top side of the top plate. The cleaning box 2 is provided with a cleaning mechanism, and the pushing mechanism is positioned at the left side of the cleaning box 2.

[0032] The pushing mechanism includes a fixed plate 402, on which four electro-hydraulic push rods 401 are correspondingly arranged, and the right end of the electro-hydraulic push rod 401 is fixedly connected with a push plate 4, and the right end inner wall of the cleaning box 2 is correspondingly provided with four accommodating Groove 201 , the right end of the electrohy...

Embodiment 2

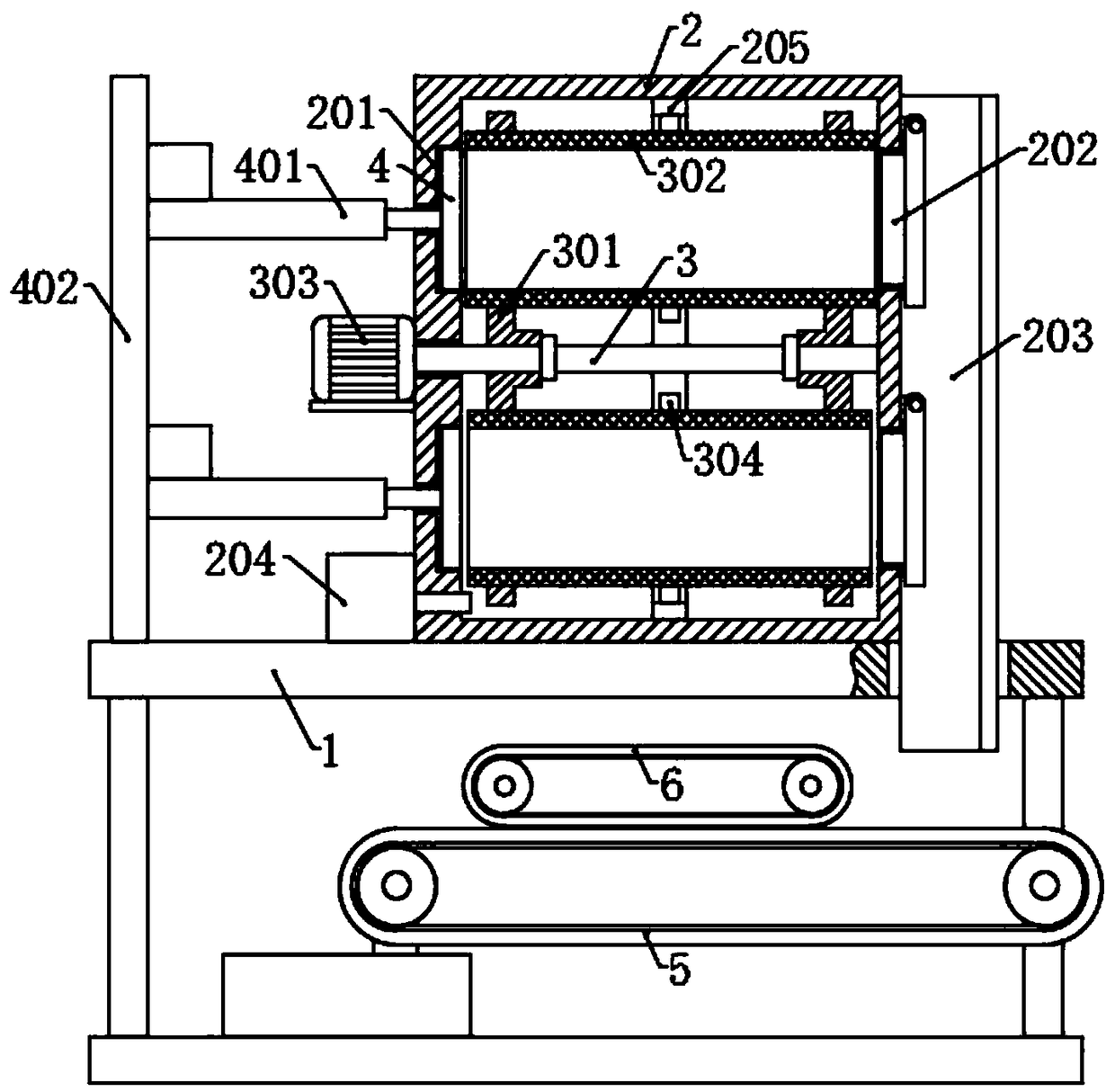

[0038] On the basis of Embodiment 1, it also includes an upper conveying mechanism 6 and a lower conveying mechanism 5, the lower conveying mechanism 5 includes two lower rollers 501, the lower roller 501 is provided with a lower conveyer belt 502, and the lower conveyer belt 502 is evenly provided with Down the water hole 503, and the outer surface of the lower conveyer belt 502 is provided with a lower sponge 504, the structure of the upper conveyer mechanism 6 is the same as that of the lower conveyer mechanism 5, correspondingly provided with an upper roller, an upper conveyer belt and an upper sponge, two upper The distance between the rollers is less than the distance between the two lower rollers 501, and the upper conveying mechanism 6 is positioned at the upper left side of the lower conveying mechanism 5, the bottom end of the material guide plate 203 is positioned at the upper right side of the lower conveying mechanism 5, and the bottom plate Correspondingly, the le...

Embodiment 3

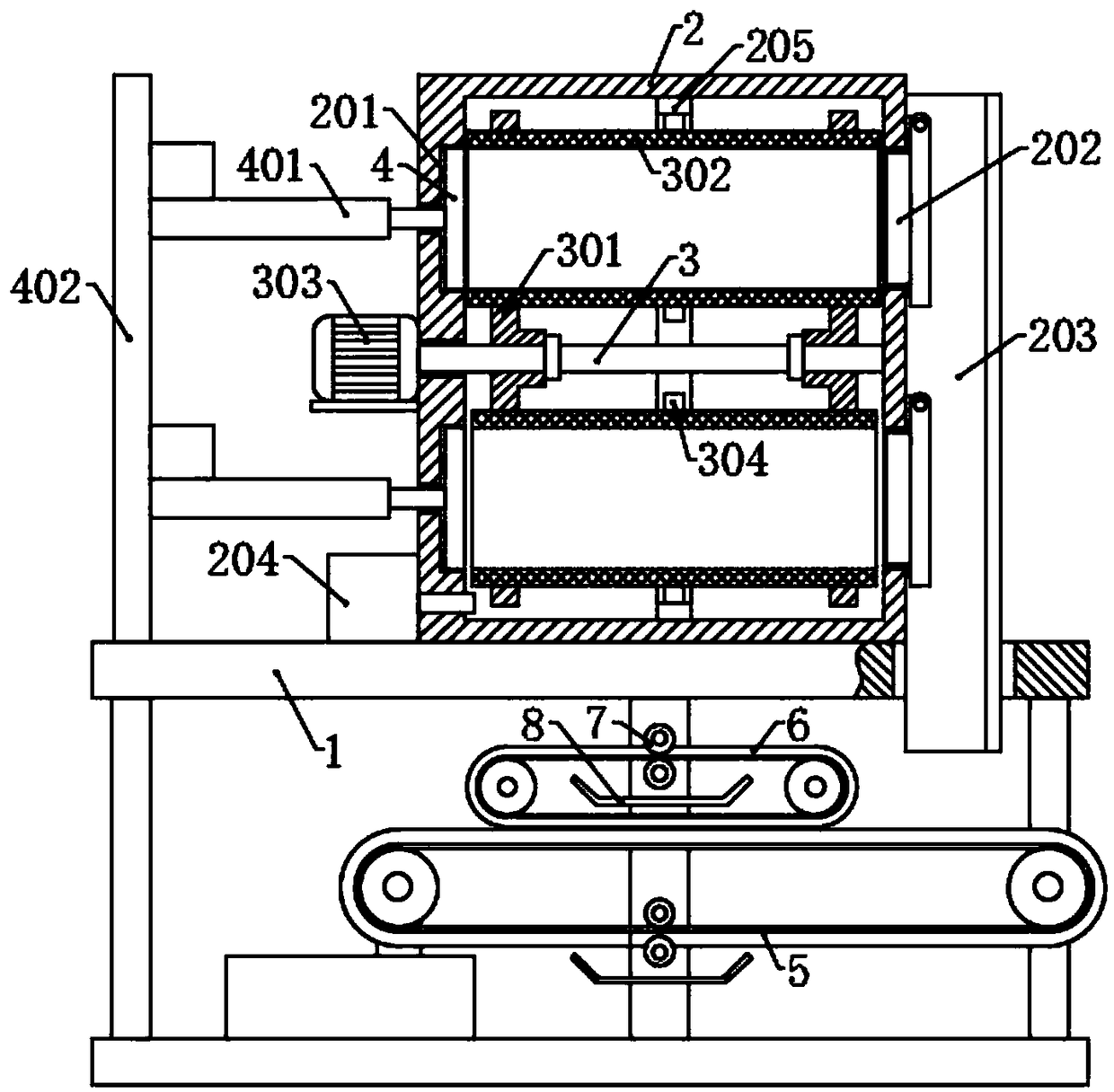

[0041] On the basis of the second embodiment, it also includes two extruding mechanisms, which are respectively arranged at the upper conveying mechanism 6 and the lower conveying mechanism 5. The extruding mechanism includes an extruding roller 7, a water guide plate 8 and a water collection tank 9, Squeeze roller 7 comprises upper pressure roller and lower pressure roller, and the water guide plate 8 that is positioned at the top is positioned at the middle of upper conveyer belt, and upper pressure roller contacts with upper sponge, and lower pressure roller contacts with upper conveyer belt, and the water guide plate 8 that is positioned at below The plate 8 is positioned below the lower conveyor belt 502 , the upper pressure roller contacts the lower conveyor belt 502 , the lower pressure roller contacts the lower sponge 504 , the water guide plate 8 is inclined, and the lower end extends into the sump 9 .

[0042] Wherein, the right end of the upper pressing roller and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com