Pharmaceutical tabletting device

A tablet-pressing device and tablet-pressing technology are applied in the direction of making drugs into special physical or ingestible devices, presses, manufacturing tools, etc., which can solve problems such as low production efficiency, prolong service life, ensure quality, Effect of improving production rate and pharmaceutical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

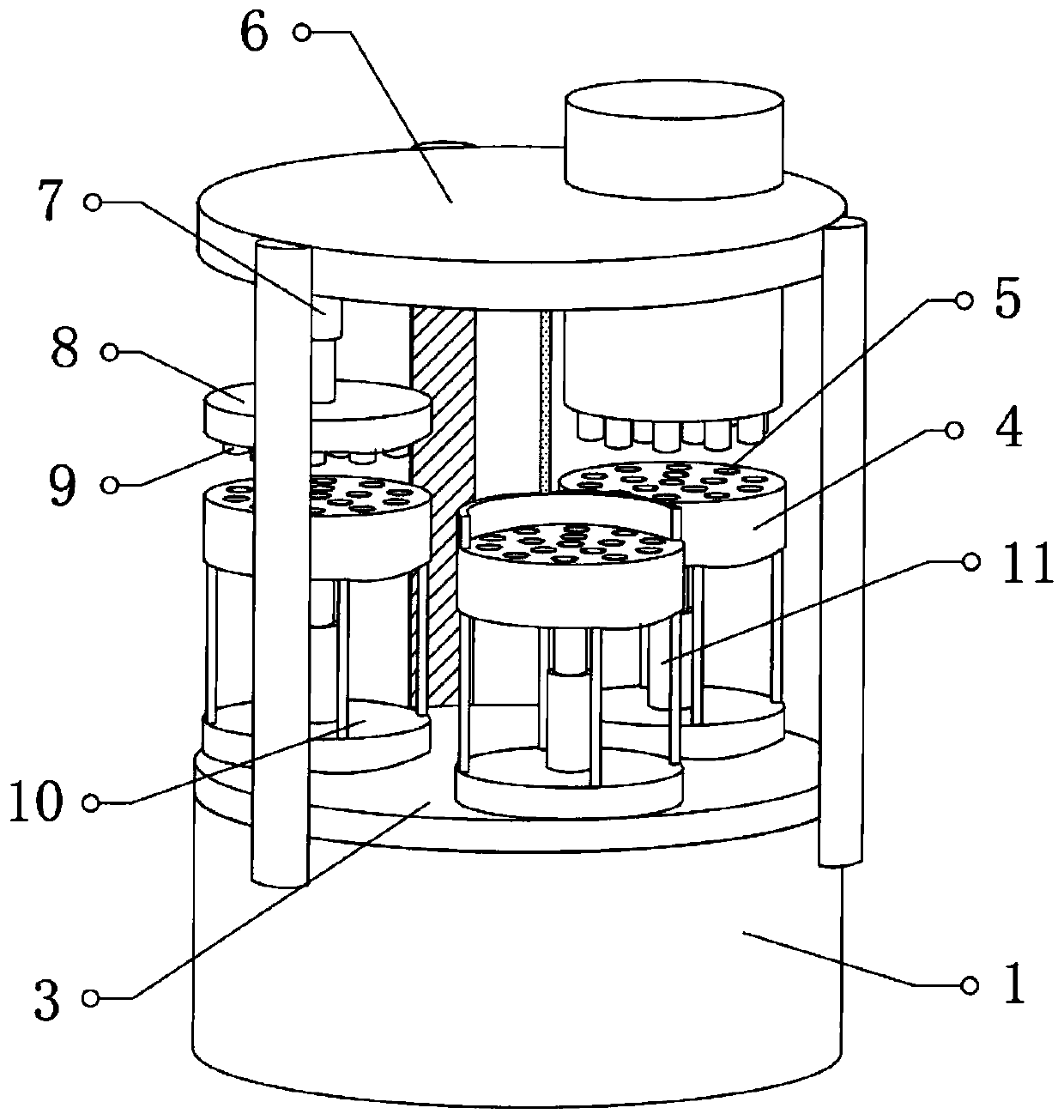

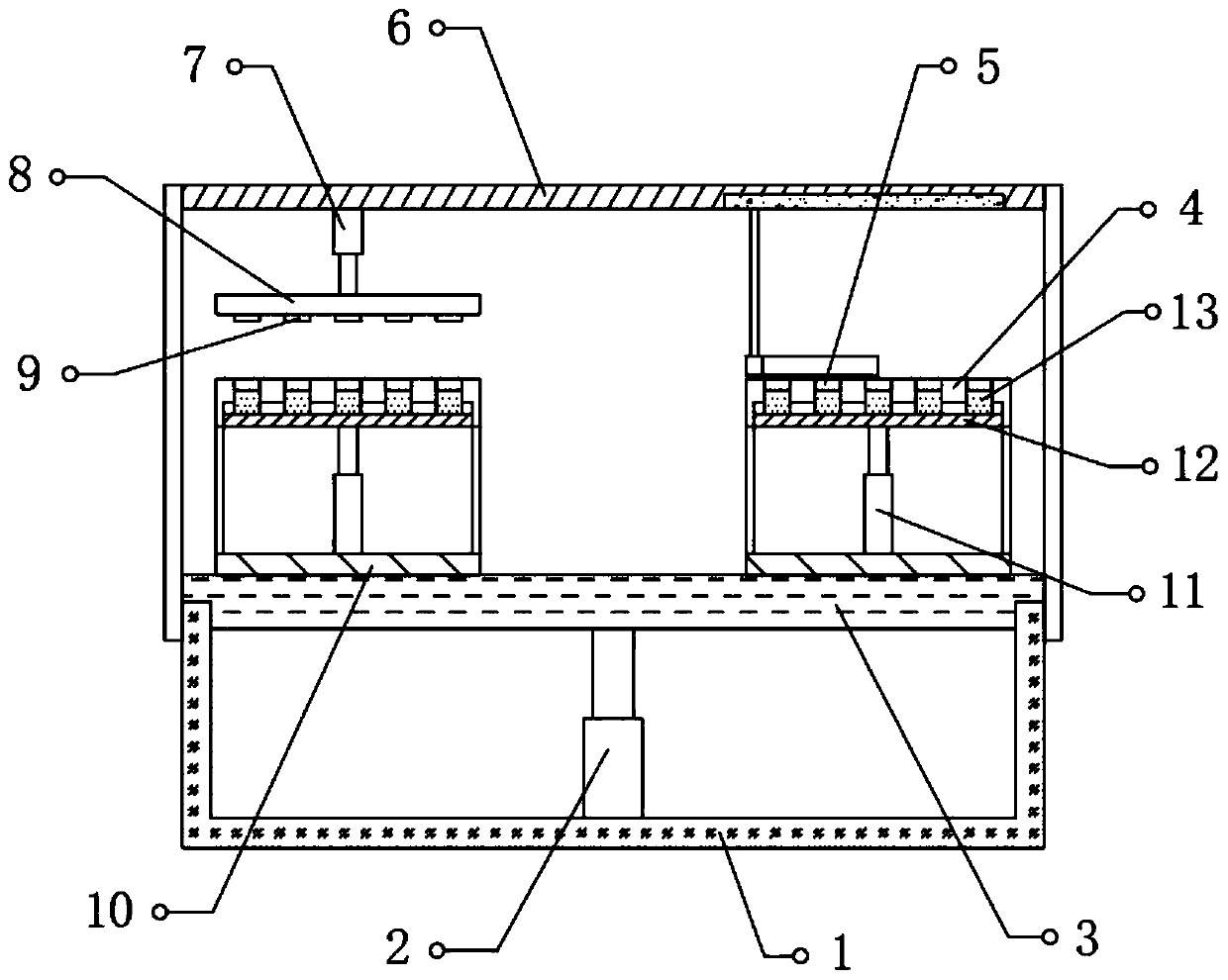

[0023] Reference Figure 1-2 , A tablet pressing device for pharmaceuticals, comprising a base box 1, the top of the base box 1 is open, the bottom inner wall of the base box 1 is fixed with a rotating motor 2, and the output shaft of the rotating motor 2 is fixed with a base 3, the bottom of the base 3 and The top of the base box 1 is rotatably connected, the top of the base 3 is fixed with three mold plates 4 distributed in an annular array, and the top of the mold plate 4 is provided with a plurality of tablet pressing grooves 5, and the top of the base box 1 is provided with a top seat 6, and A plurality of support frames are fixed between the top base 6 and the outer wall of the base box 1, and the bottom of the top base 6 and the mold plate 4 are fixed with a charging mechanism, a tablet pressing mechanism and a discharging mechanism.

[0024] In the present invention, the charging mechanism is provided with a storage cylinder fixed on the top seat 6, and the bottom of the ...

Embodiment 2

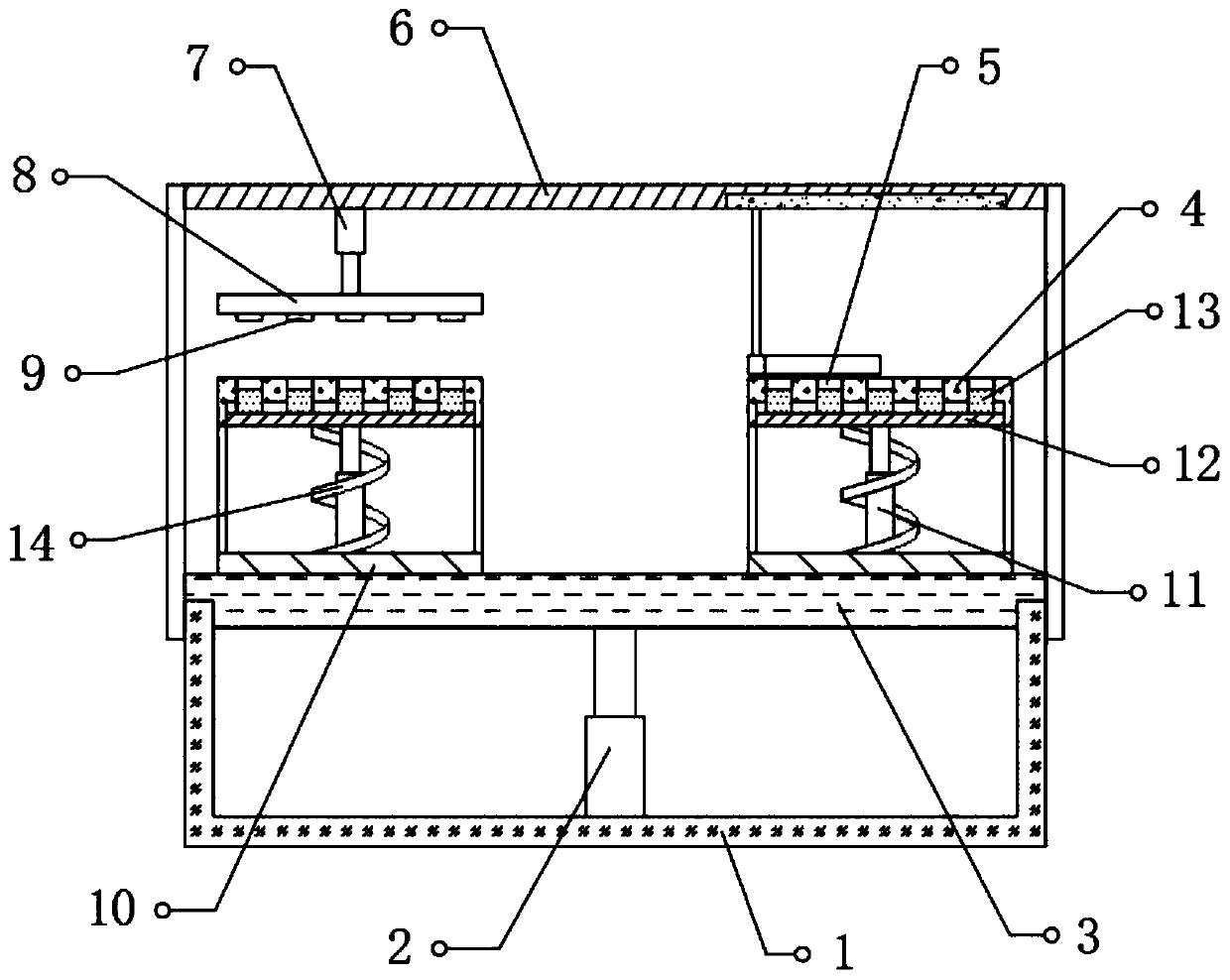

[0029] Reference image 3 , A tablet pressing device for pharmaceuticals, a spring 14 is fixed between the bottom of the limiting plate 12 and the bottom plate 10, and the spring 14 is sleeved outside the electric push rod 11.

[0030] Working principle: Further, a spring 14 is fixed between the limit plate 12 and the bottom plate 10 of the device, and the spring 14 is sleeved on the outside of the electric push rod 11, and the cushioning performance of the spring 14 is used to reduce the electric push rod during the pressing process. 11 is damaged by force, so as to ensure the stability of the limit block 13, ensure the quality of the pressed tablet, and extend the service life of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com