Blanking convenient molding powder stirring storage integrated machine

An all-in-one and blanking technology, applied in the field of plastic powder production equipment and plastic powder mixers, can solve the problems of product quality impact, easy to have dead ends, insufficient mixing of raw materials, etc., to improve product quality, avoid pollution, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

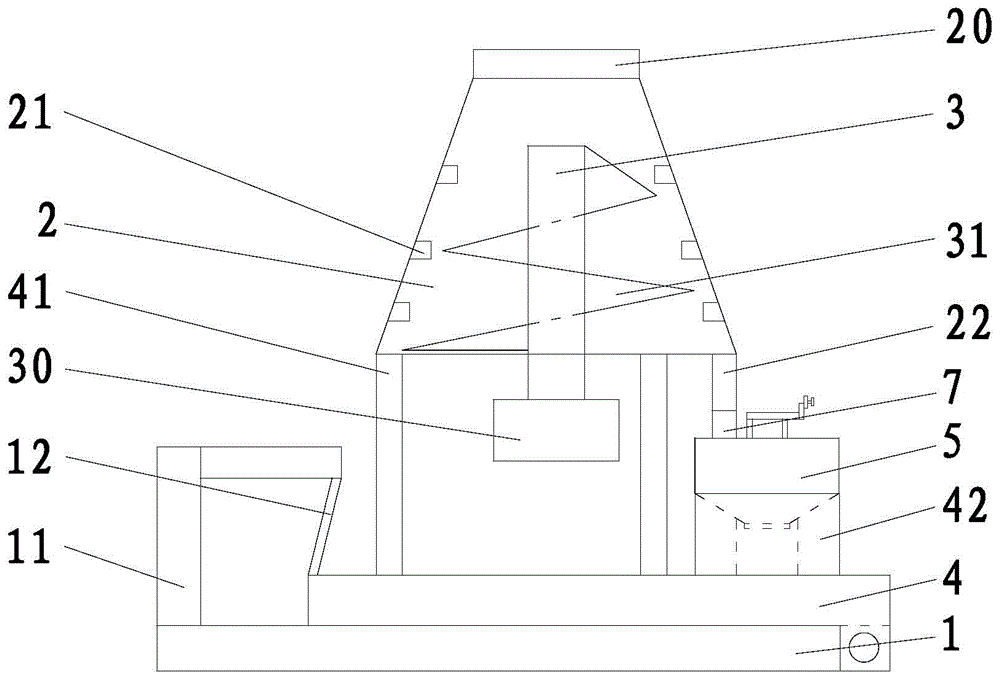

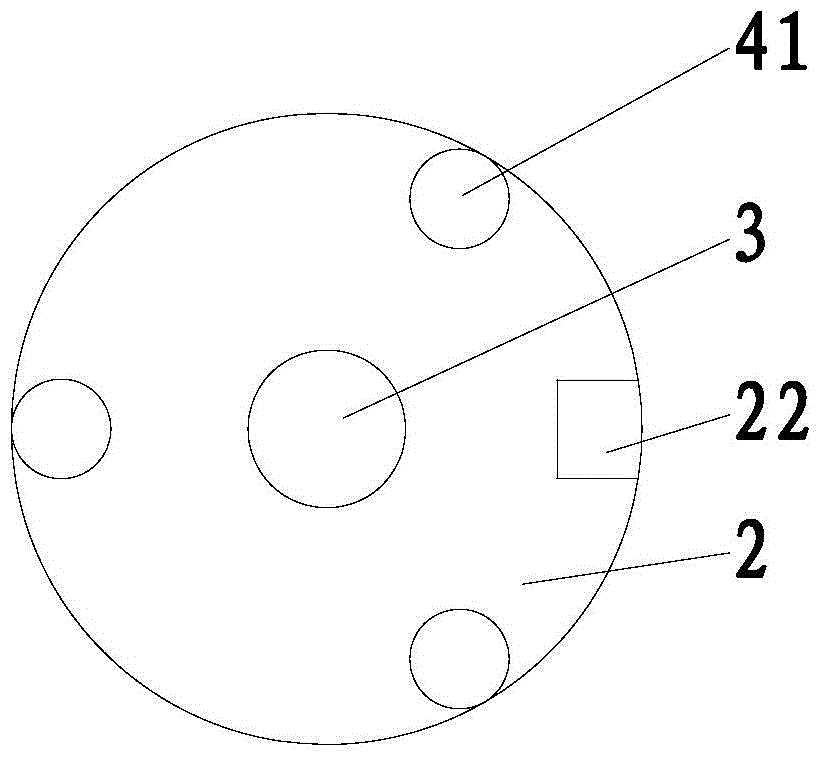

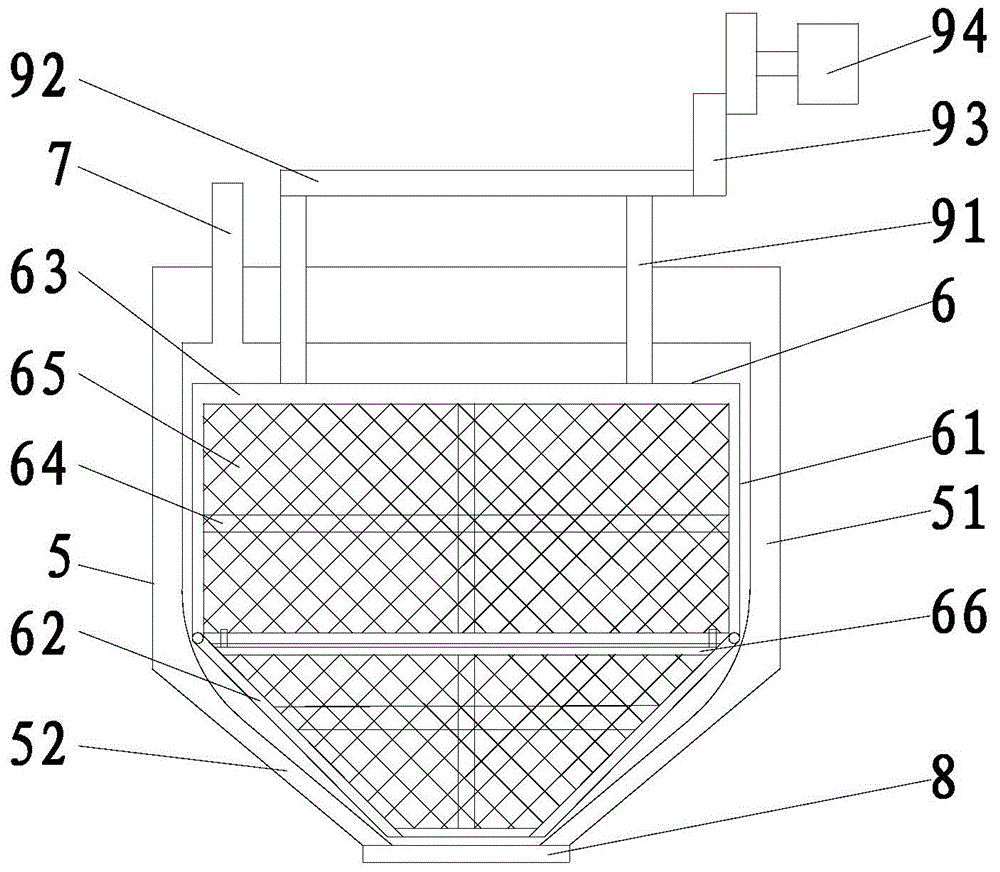

[0018] refer to figure 1 , figure 2 , image 3 with Figure 4 , invented a plastic powder mixing and storage integrated machine for convenient blanking, including a base 1, a support plate 4, a cylinder 2, a rotating shaft 3, a storage cylinder 5, an inlet door 7, an outlet door 8, and a scraper body 6. The interior of the cylinder 2 is hollow, and the hollow part of the cylinder 2 is in the shape of a truncated cone. There is a cylinder cover 20 on the top of the cylinder 2, and a number of heating blocks 21 are distributed on the inner wall of the cylinder 2. The rotating shaft 3 starts from the center of the bottom of the cylinder 2. Extending into the cylinder 2, the rotating shaft 3 is connected with a motor 30 at the outer end of the cylinder 2, and there is a spiral blade 31 on the rotating shaft 3 in the cylinder 2, and the bottom edge of the cylinder 2 is provided with a discharge port 22 The bottom of cylinder body 2 is provided with several support rods 41, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com