Concrete rotary stirring and mixing device for building construction

A rotary mixing and building construction technology, applied in the field of concrete mixing, can solve the problems of insufficient mixing, too much concrete, and inability to disperse concrete, and achieve the effect of improving the mixing adequacy, reducing the amount of concrete, and the mixing process being sufficient and efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

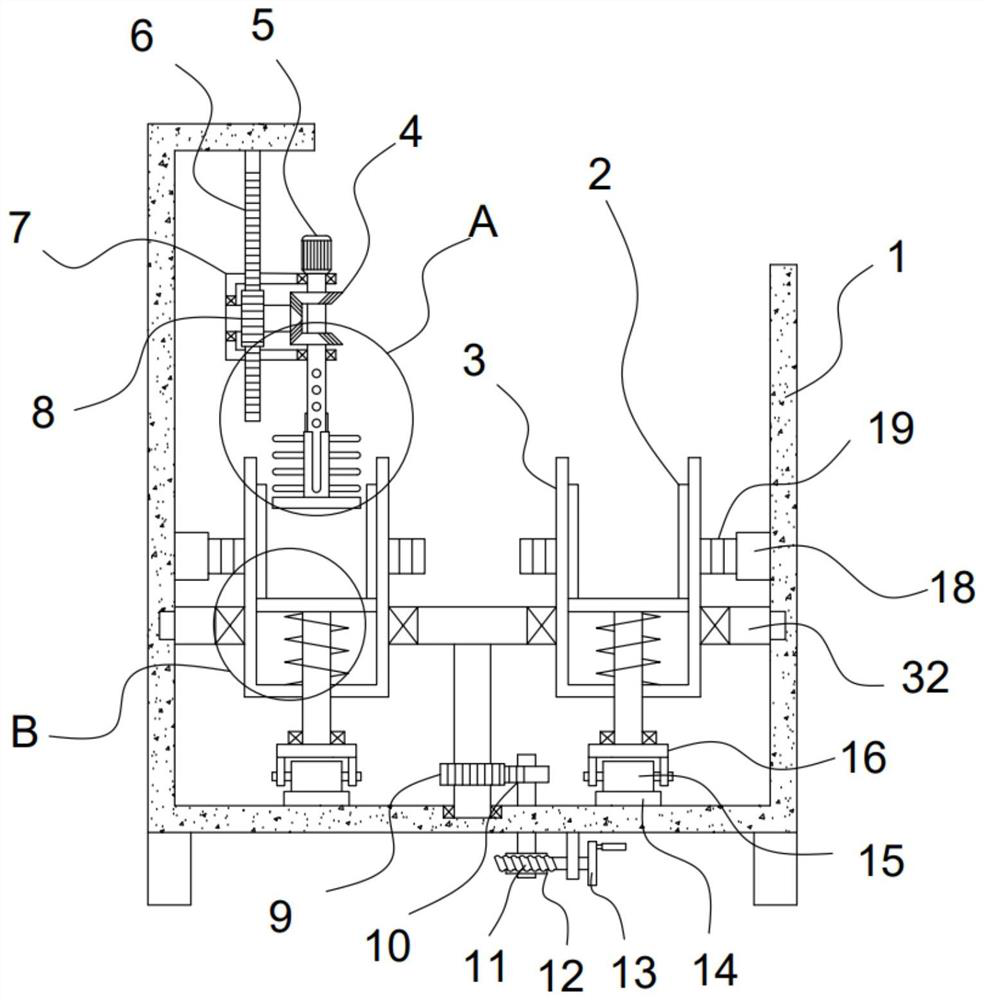

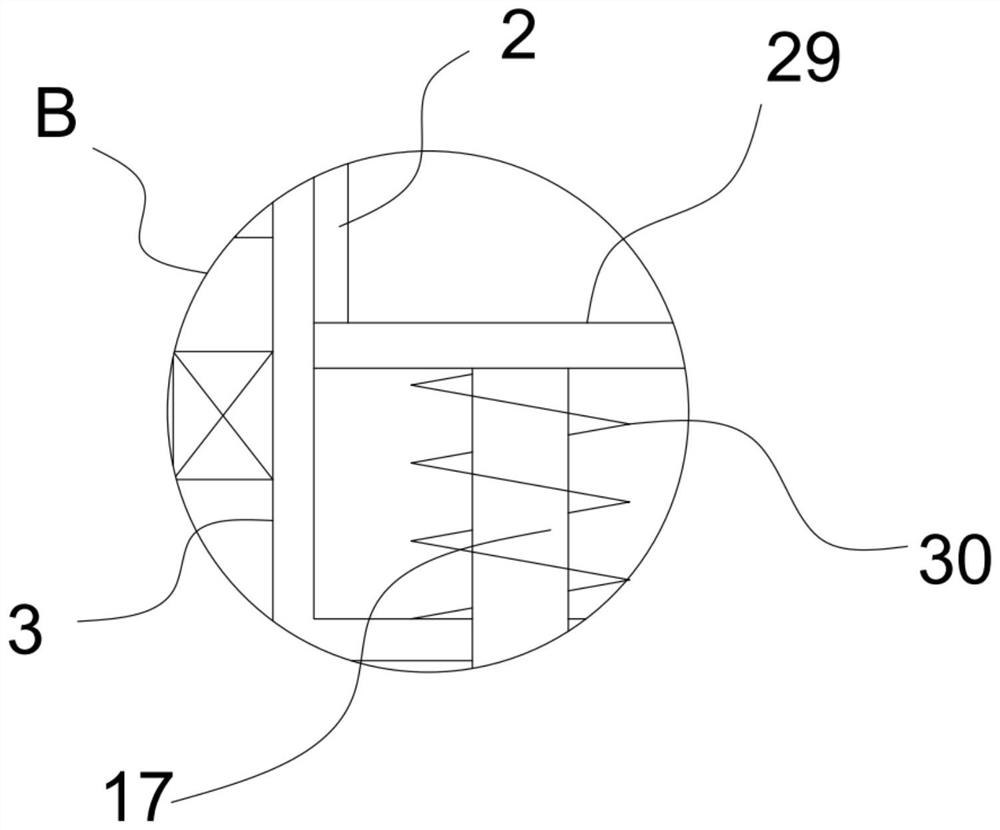

[0022] see Figure 1-4 , a concrete rotary mixing and mixing device for building construction, including a fixed frame 1, a rotating plate 32 is mounted on the fixed frame 1, and a plurality of rotating mixing buckets 3 are evenly installed on the rotating plate 32 in the circumferential direction, The vertical rack 6 is vertically fixed on the fixed frame 1, and the vertical rack 6 is slidably provided with a lifting frame 7 for vertical lifting. mechanism, the bottom of the fixed frame 1 is provided with a step-by-step drive mechanism for driving the rotating plate 32 to rotate step by step, and a reciprocating lifting mechanism is vertically connected between the mixing bucket 3 and the fixed frame 1 .

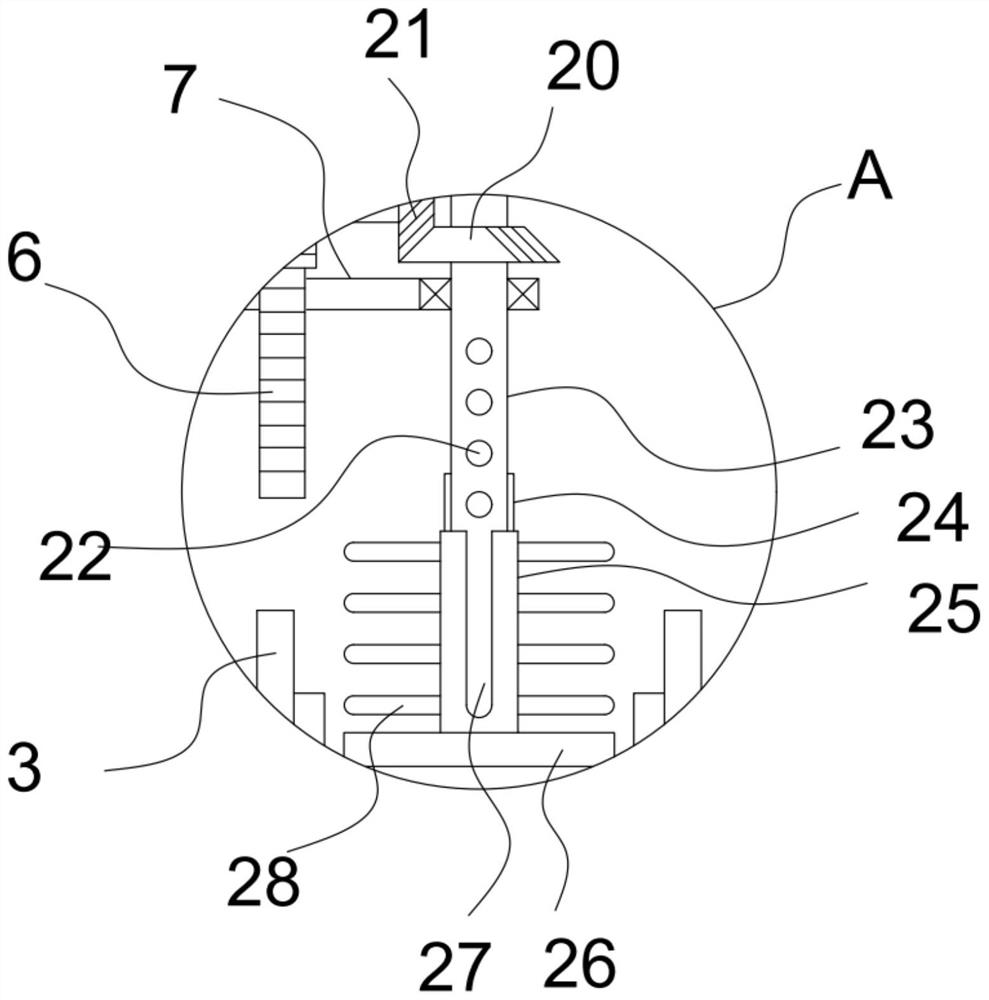

[0023] The multiple mixing barrels 3 provided in the device are used to store the concrete to be stirred, and the provided stirring mechanism rotates and mixes the concrete in the multiple mixing barrels 3 . Stirring includes rotating a rotating shaft 23 installed on the l...

Embodiment 2

[0029] On the basis of Embodiment 1, in addition, the stepping drive mechanism of this device includes the driven gear 9 that is rotatably installed on the fixed frame 1, the driven gear 9 is coaxially fixed with the rotating plate 32, and the fixed frame 1 rotates An incomplete gear 10 intermittently meshed with the driven gear 9 is installed, a worm wheel 12 is coaxially fixed on the incomplete gear 10, a worm 11 is meshed with the worm wheel 12, and a runner 13 is fixed at the end of the worm 11.

[0030] Rotating the rotating wheel 13 can drive the worm 11 to rotate for one week, and the worm 11 drives the meshed worm gear 12 to rotate, and the worm gear 12 drives the incomplete gear 10 to rotate for one circle, and the incomplete gear 10 drives the driven gear 9 to rotate at a certain angle to realize the next stirring The bucket 3 can replace the previous mixing bucket 3 and rotate to the right below the mixing mechanism, realizing the effect of rotating and stirring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com