Stirring device for fully stirring catalyst and degraded plastic organisms

A technology for degrading plastics and stirring devices, which is applied to mixers with rotating stirring devices, mixer accessories, dissolution, etc. It can solve the problems of reducing stirring efficiency, insufficient grinding, and increasing stirring time, so as to improve stirring sufficient rate and increase Stirring efficiency and the effect of reducing stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

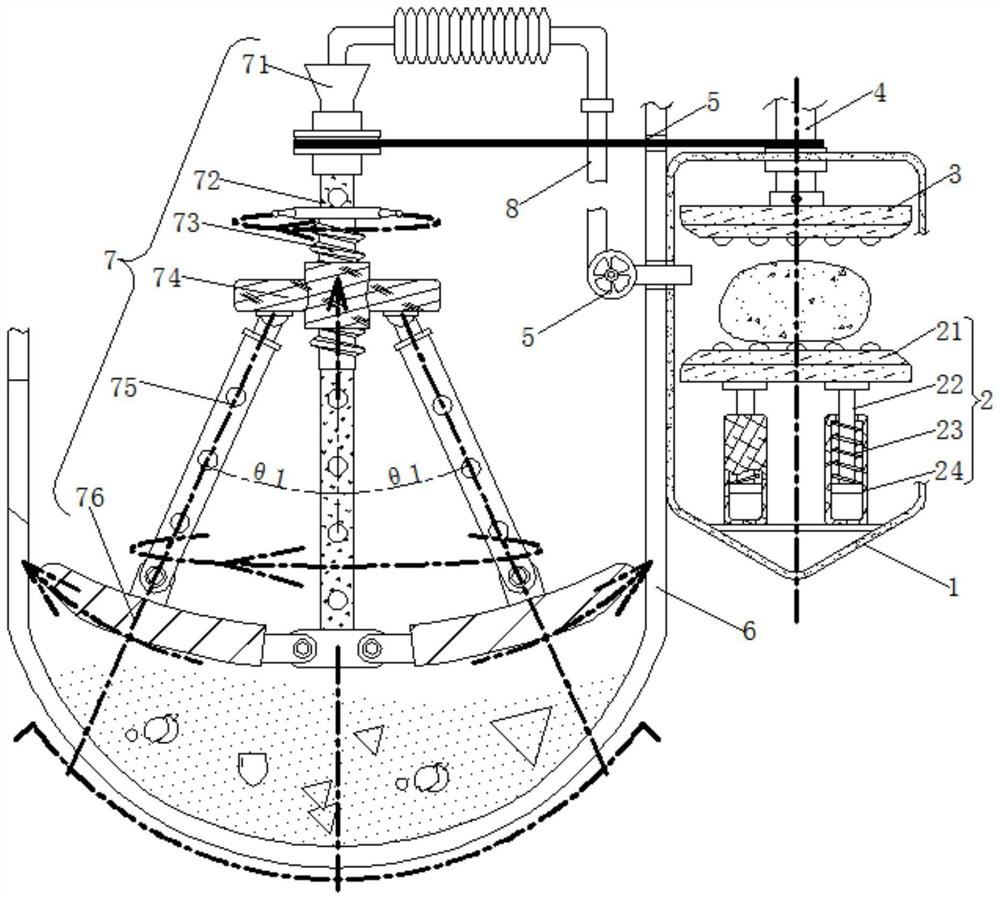

[0025] see Figure 1-2 , a stirring device for fully stirring catalysts and biodegradable plastics, comprising a grinding box 1, an upper grinding disc 3 is installed movable inside the grinding box 1, a rotating shaft 4 is fixedly installed in the middle of the upper grinding disc 3, and the left side of the grinding box 1 A fan 5 is fixedly installed on the side, a stirring box 6 is fixedly installed on the left side of the grinding box 1, and a feeding port is arranged on the left side of the stirring box 6 . A pipeline 8 is installed above the fan 5 .

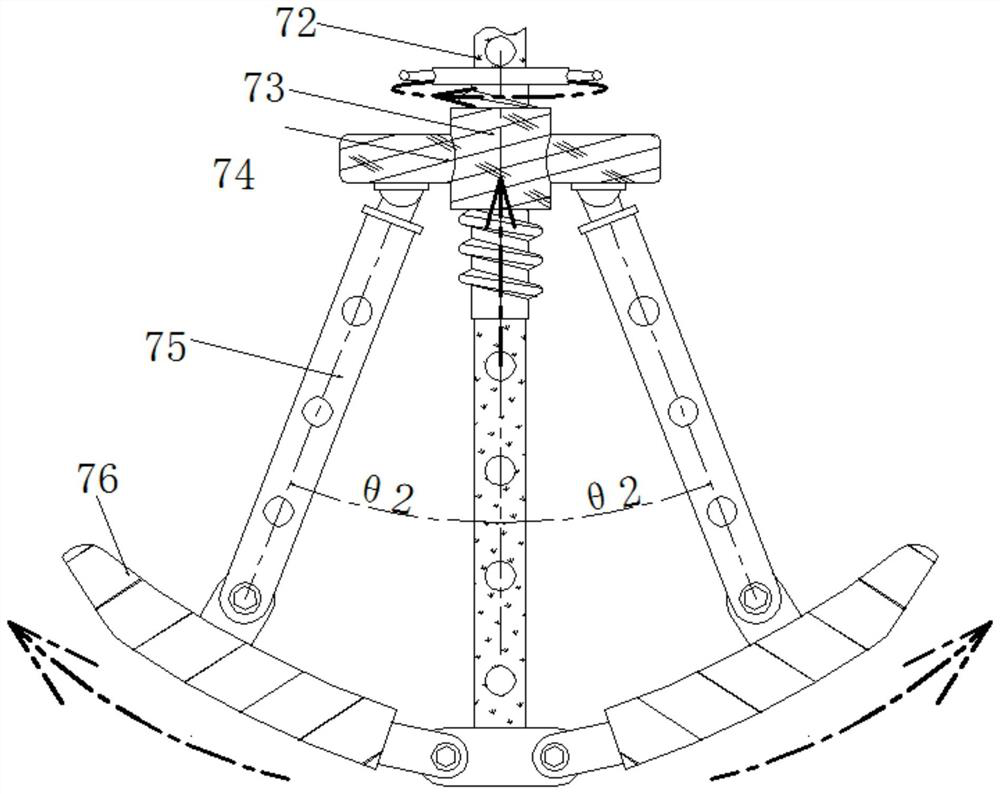

[0026] Including a stirring mechanism 7, a funnel 71 is installed on the top of the stirring mechanism 7, a main rod 72 is installed on the bottom of the funnel 71, a threaded rod 73 is installed on the top of the main rod 72, and a connecting block 74 is threaded in the middle of the threaded rod 73 , Both sides of the connection block 74 are movably equipped with struts 75, and the front and rear sides of the strut 75 ar...

Embodiment 2

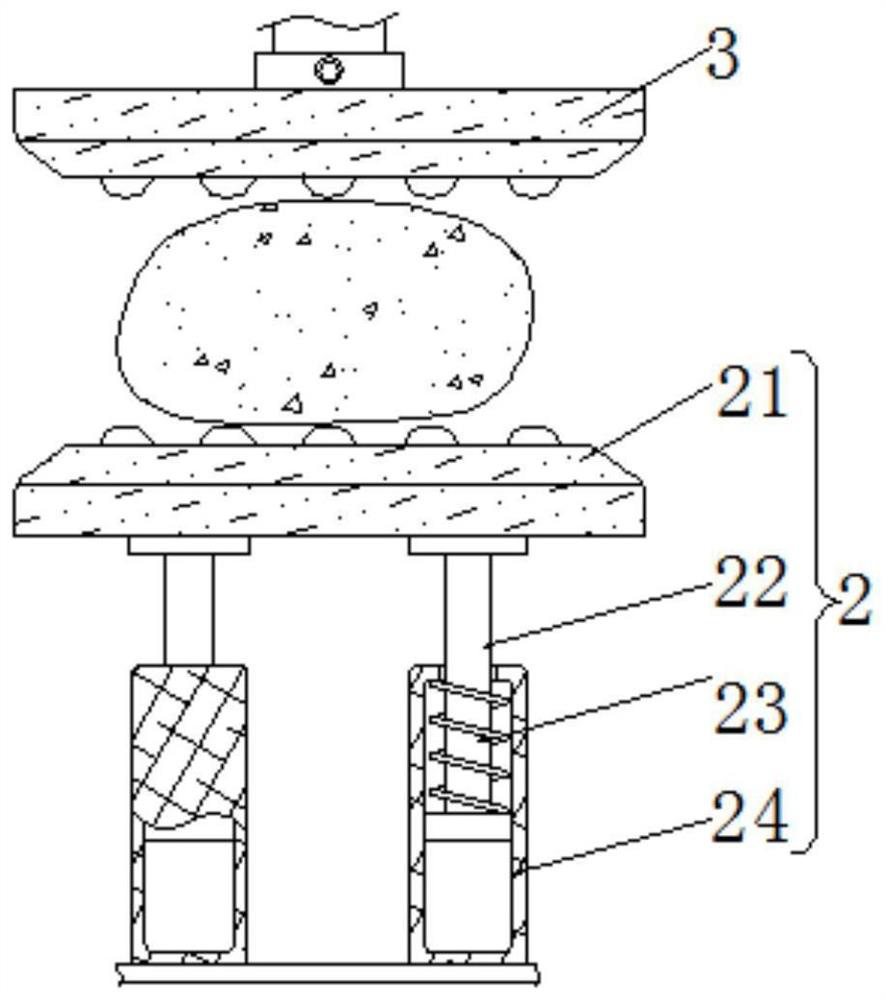

[0028] see figure 1 , 3 , a stirring device for fully stirring catalysts and biodegradable plastics, comprising a grinding box 1, an upper grinding disc 3 is installed movable inside the grinding box 1, a rotating shaft 4 is fixedly installed in the middle of the upper grinding disc 3, and the left side of the grinding box 1 A fan 5 is fixedly installed on the side, a stirring box 6 is fixedly installed on the left side of the grinding box 1, and a feeding port is arranged on the left side of the stirring box 6 . A pipeline 8 is installed above the fan 5 .

[0029] The middle part of the grinding box 1 is movably equipped with a grinding device 2, a lower grinding disc 21 is arranged above the grinding device 2, and a piston rod 22 is fixedly installed below the lower grinding disc 21, and a spring 23 is sleeved on the outside of the piston rod 22, and the piston rod The below of 22 is fixedly equipped with cylinder 24. The bottom of the piston rod 22 is installed inside th...

Embodiment 3

[0031] see Figure 1-3 , a stirring device for fully stirring catalysts and biodegradable plastics, including a stirring mechanism 7, a funnel 71 is movable above the stirring mechanism 7, a main rod 72 is movable below the funnel 71, and a screw thread is movable above the main rod 72 Rod 73, the middle part of threaded rod 73 is threadedly connected with connection block 74, and the both sides of connection block 74 are movably equipped with support rod 75, and the front and rear sides of support rod 75 evenly offer air-draining hole. The side of the pipe 8 away from the fan 5 is set above the funnel 71, the middle part of the main rod 72 is a hollow structure, and the front and rear sides are uniformly provided with air-draining holes, and the side of the funnel 71 away from the pipe 8 is sleeved on the top of the pole 75 Hollow position in the middle. A support rod 76 is movably installed on the side of the pole 75 away from the connecting block 74 . Support bar 76 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com