Quick-assembling combined door plate

A door panel and quick installation technology, applied in door leaf, window/door, fire door, etc., can solve the problems of easy entry of dust and insects, low production efficiency, and deformation of wood glue, to avoid glue deformation and toxic residues , The effect of improving fire prevention and anti-corrosion performance and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

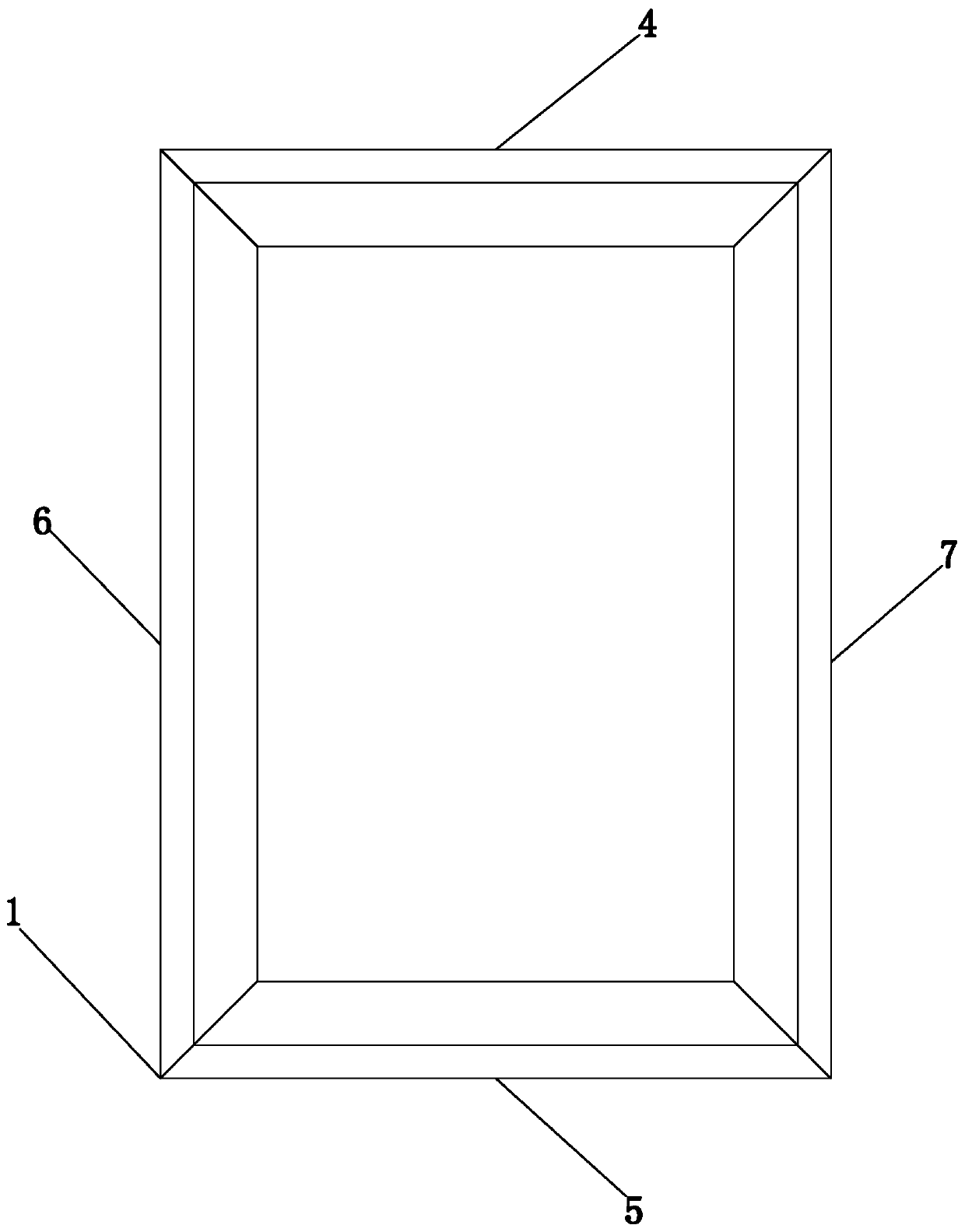

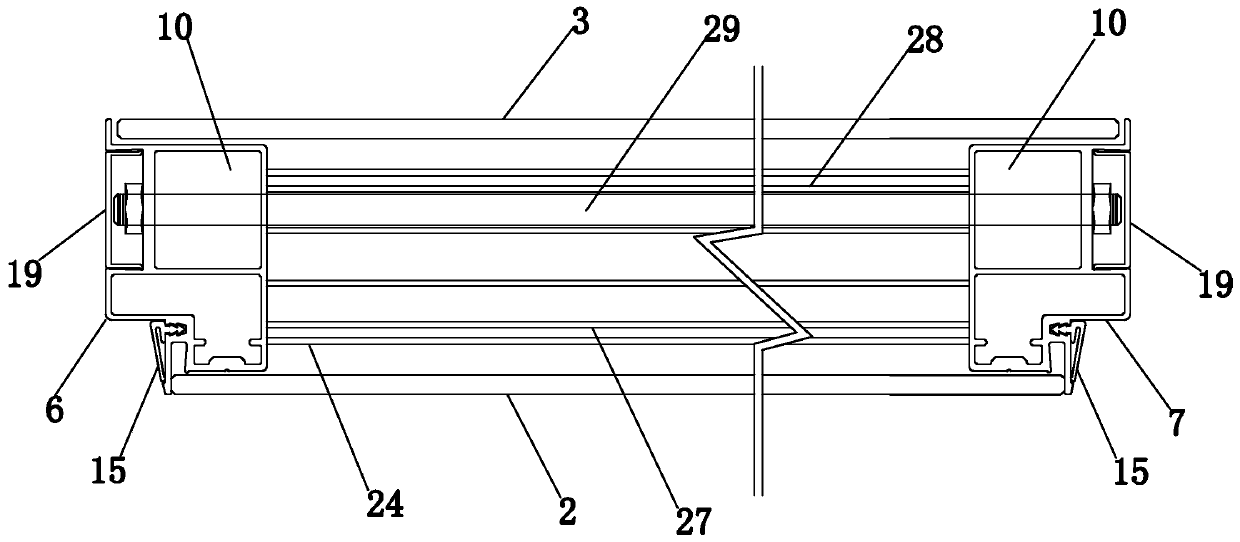

[0033] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , the present embodiment is a quick assembly door panel, including a keel frame 1, a front panel 2 and a rear panel 3, the keel frame 1 is rectangular, and the upper frame 4 and the lower frame 5 are cut at 45 degrees by both ends. The left frame 6 and the right frame 7 are spliced together, and the upper frame 4, the lower frame 5, the left frame 6 and the right frame 7 are all composed of door frame keels 8;

[0034] The left and right sides of the door frame keel 8 are divided into a left chamber 9 with a "┑"-shaped cross section and a right chamber 10 with a rectangular cross section. The left lower corner of the left chamber 9 is recessed to form a square corner 11, and the middle part of the horizontal side of the square corner 11 protrudes downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com