Stator for reciprocating motor and fabrication method thereof

A reciprocating and stator technology, which is used in the manufacture of motor generators, stator/rotor bodies, and electric components, etc., can solve the problems of high manufacturing costs and complex manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

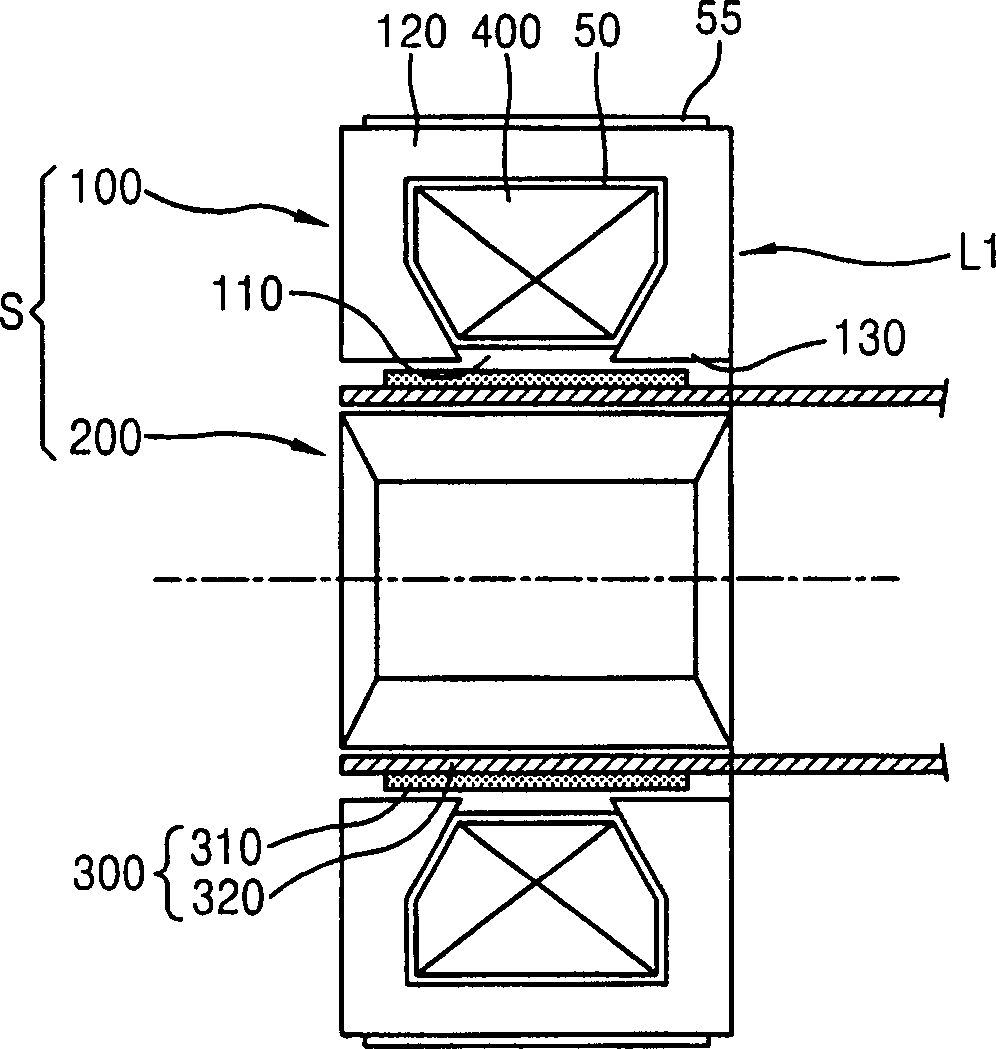

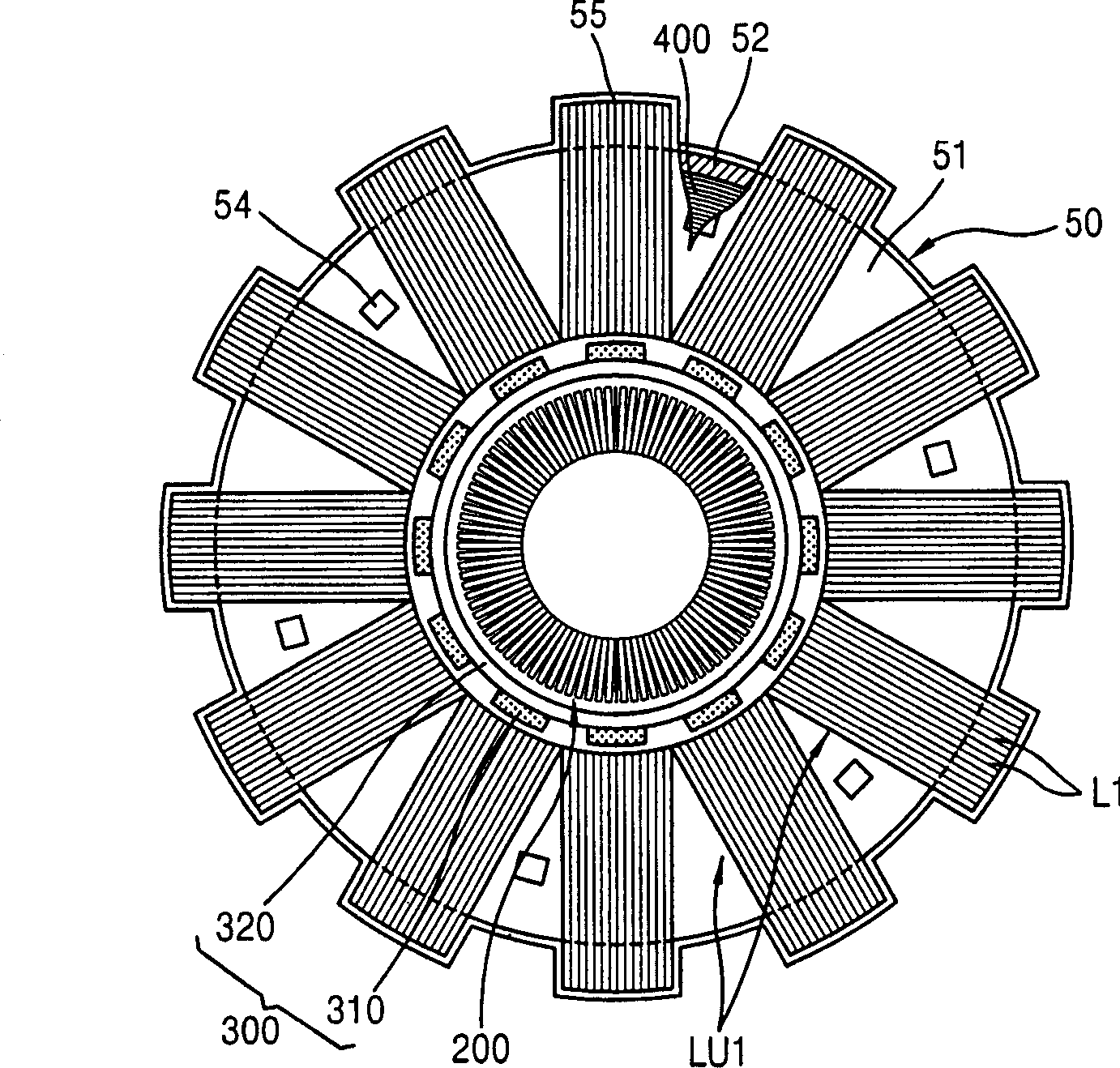

[0037] Fig. 4 is a cross-sectional view showing a reciprocating motor having a stator according to the present invention.

[0038] As shown therein, a reciprocating motor includes a stator S having an outer core 100 and an inner core 200 disposed in the outer core 100, and a mover 300 movably inserted between the outer core 100 and the inner core 200 of the stator S. in the gap between. The mover 300 includes one or more permanent magnets 310 and a magnet holder 320 for holding the permanent magnets 310 .

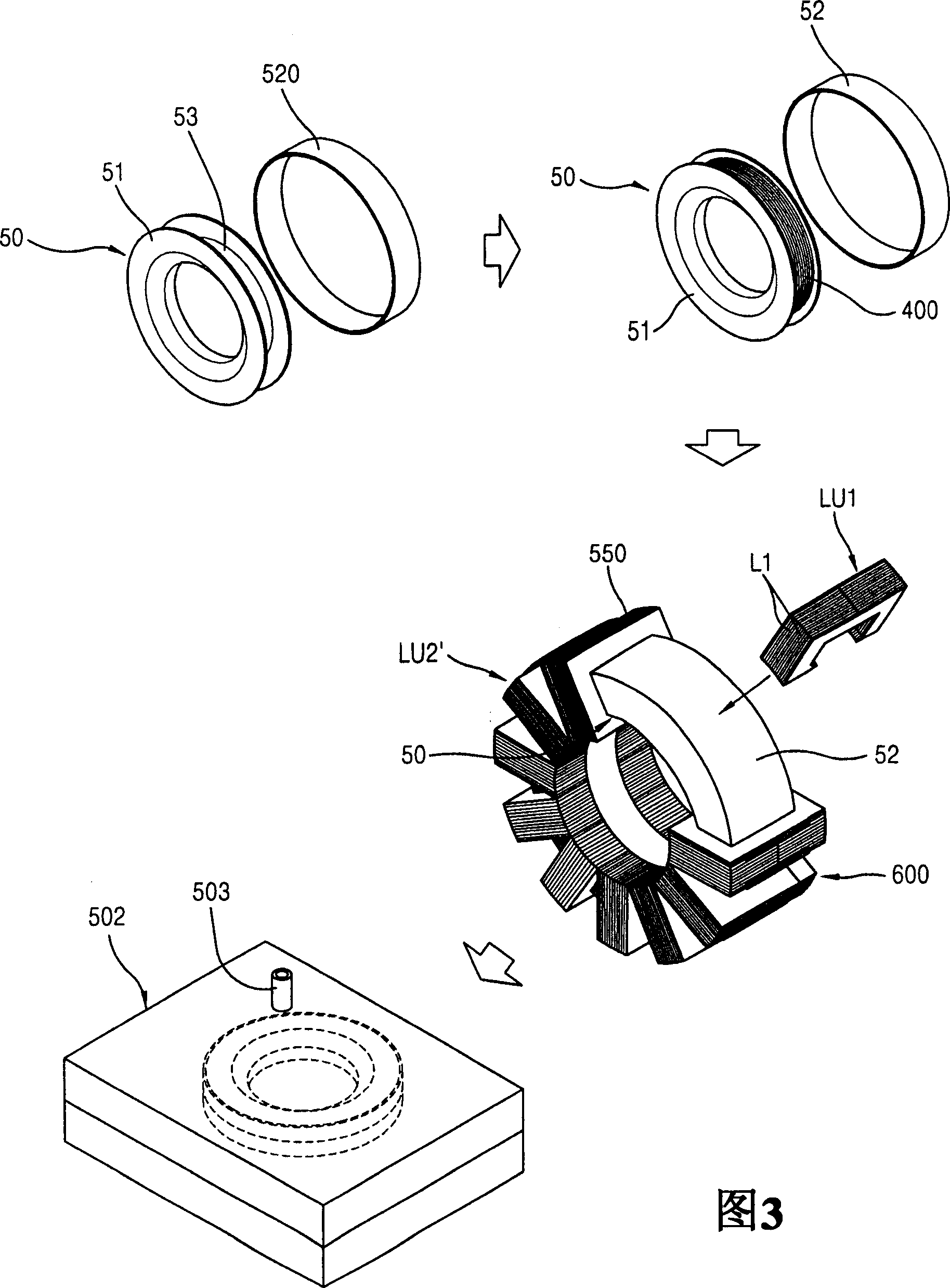

[0039] The outer core 100 includes a toroidal coil winding 400 in which the coil is wound multiple times and is fastened and insulated by an adhesive material 710 distributed between the coil windings; a circular strip shape for forming the insulating layer; an annular bobbin 500 comprising two halves 510 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com