Laser additive manufacturing forming method of static mixer

A static mixer and laser additive technology, applied in the field of 3D printing, can solve the problems of difficulty in molding and warping deformation, and achieve a combination of printing efficiency, enhanced hardness and wear resistance, and avoid dimensional errors and defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

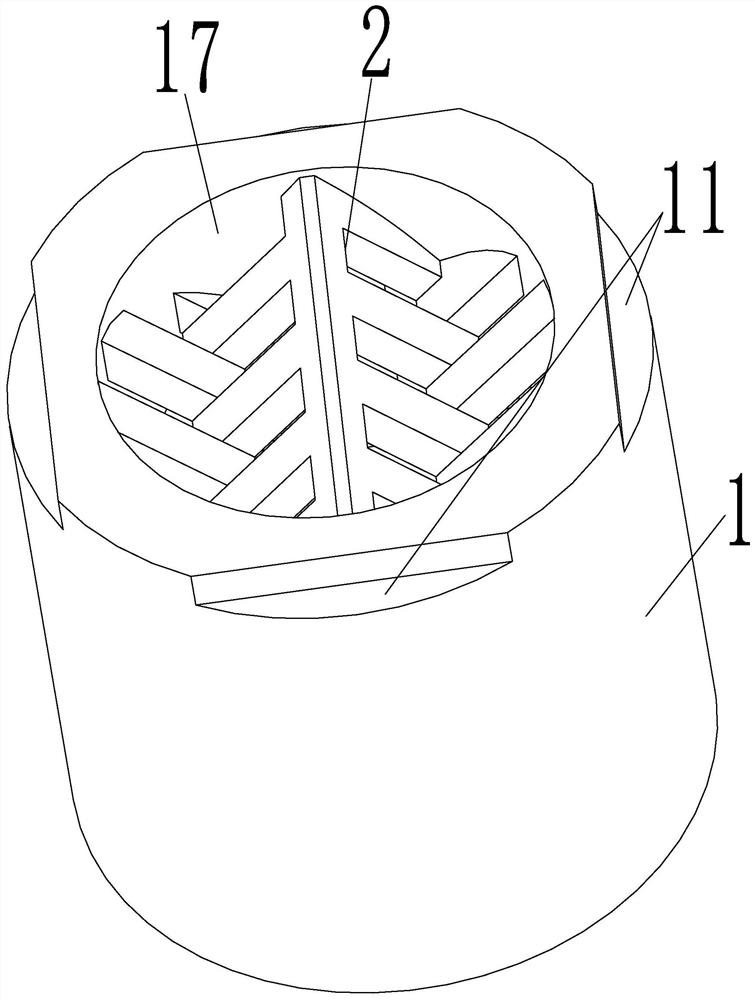

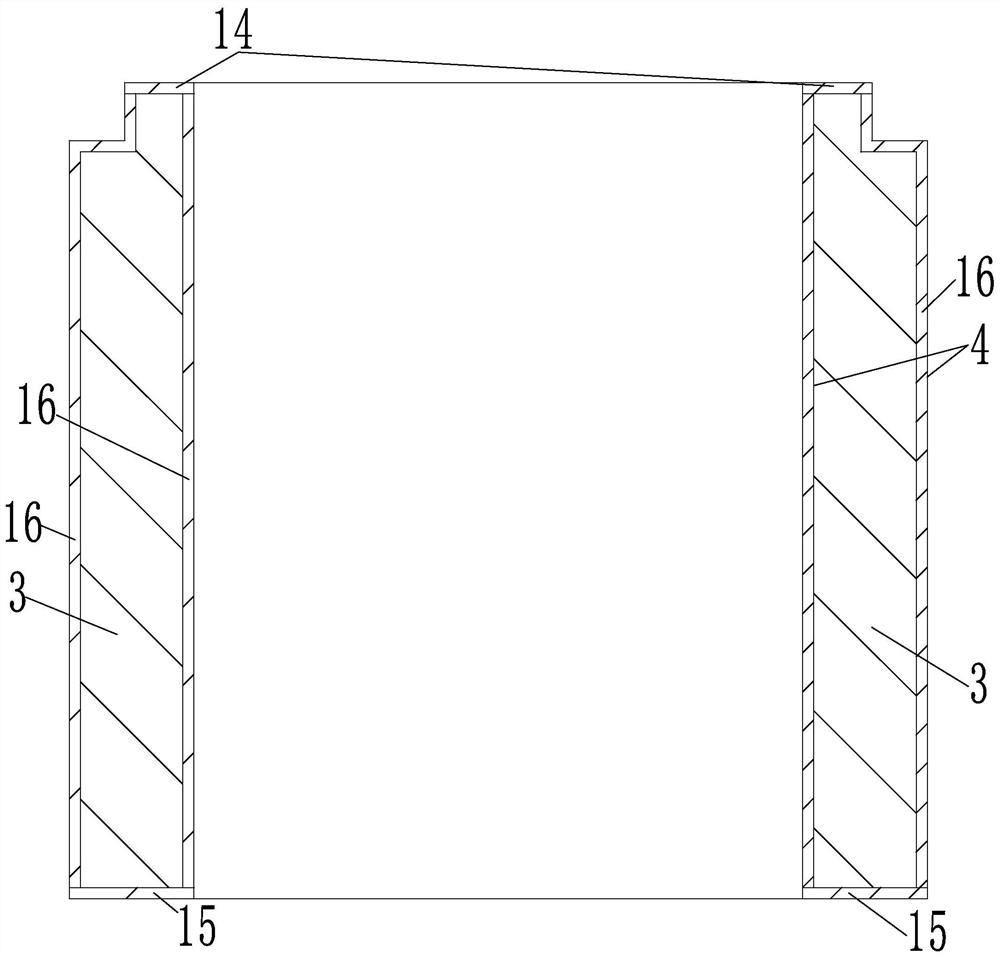

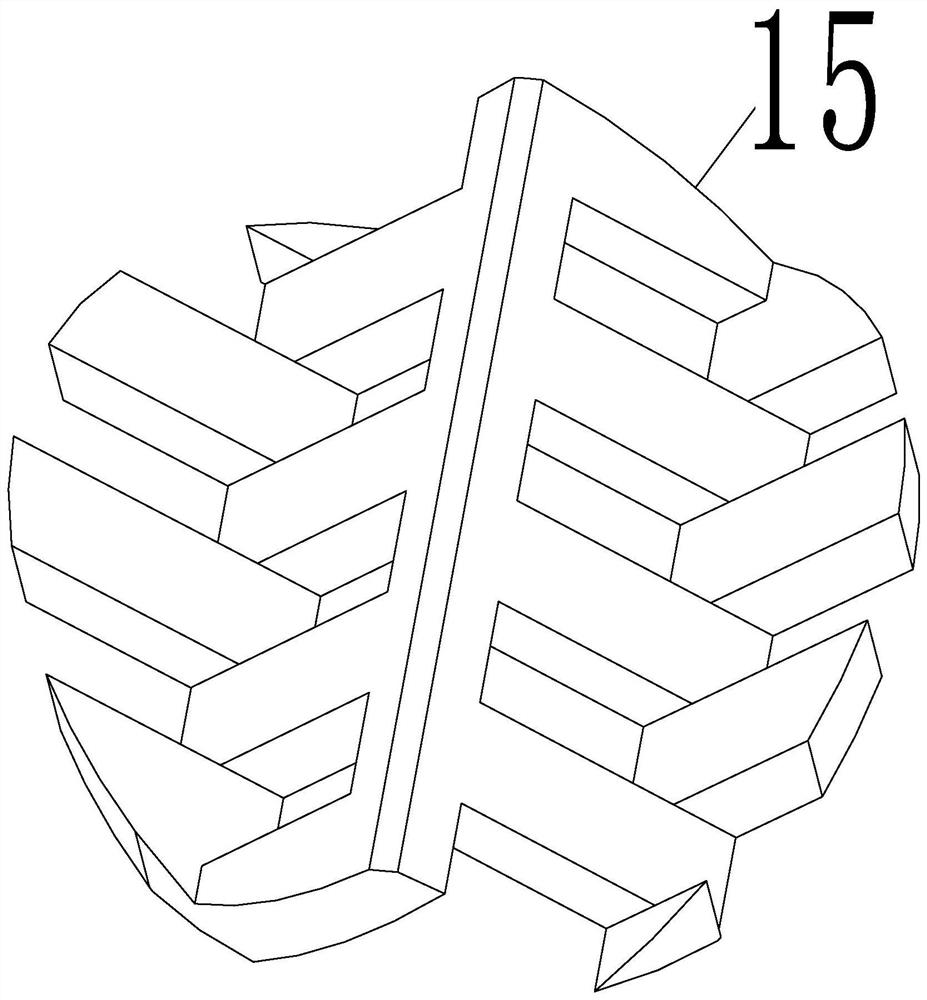

[0028] Depend on Figure 1 to Figure 4 As shown, the laser additive manufacturing molding method of the static mixer of the present invention includes a housing 1, the housing 1 is provided with a through hole 17, and one end of the housing 1 is provided with a plurality of locking grooves 11 along the circumferential direction. A plurality of W-shaped elements 2 are fixedly connected in the through hole 17; the housing 1 and each W-shaped element 2 are equally divided into an inner core 3 and an outer shell 4; the outer shell 4 of the shell 1 is divided into an upper surface 14 of the shell , housing lower surface 15 and housing profile 16; the outer shell 4 of each W-shaped element 2 is divided into element upper surface 24, element lower surface 25 and element outline 26, and the above-mentioned inner core 3 and outer shell 4 are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com