Circumferential weld structure of water heater water tank liner and welding method

A water heater water tank and girth seam welding technology, which is applied to welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of water heater water tanks such as water leakage, and achieve the effect of convenient docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

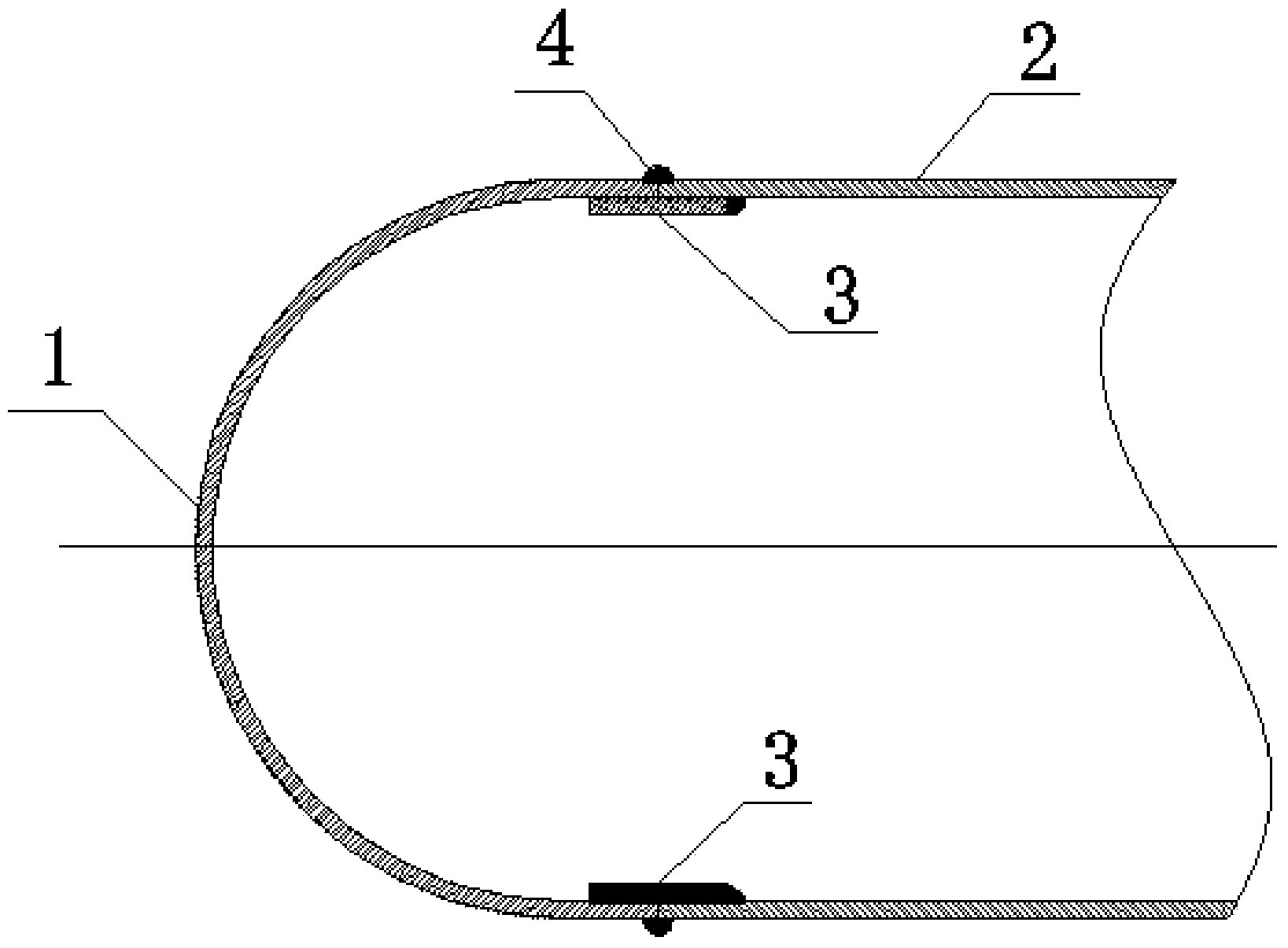

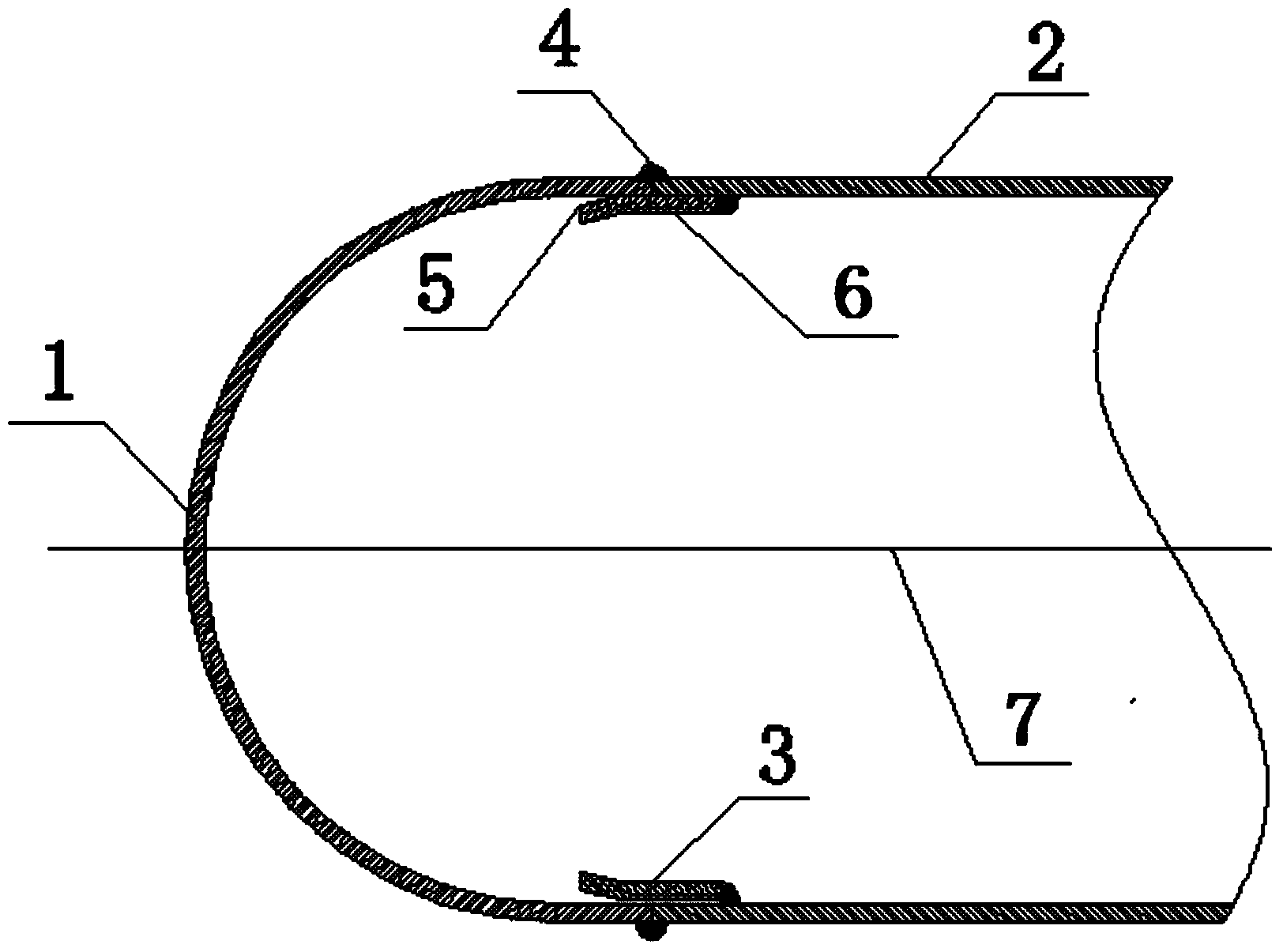

[0032] see figure 1 , figure 2 , the present invention provides a kind of girth welding method of the water tank liner of a water heater, welding the water tank head 1 and the water tank body 2 together, comprising the steps of:

[0033] A. Weld the substrate 3 to the opening edge of the water tank body 2:

[0034] The longitudinal cross-sectional shape of the substrate 3 is a combination of a flat plate 6 and an inclined surface 5, the flat plate 6 is provided with two end surfaces, the inclined surface 5 is connected with the first end surface of the flat plate 6, and the angle between the two is 160-175°. The included angle should not be too large, so as to avoid that the inclined surface 5 of the substrate cannot play the role of assisting the posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com