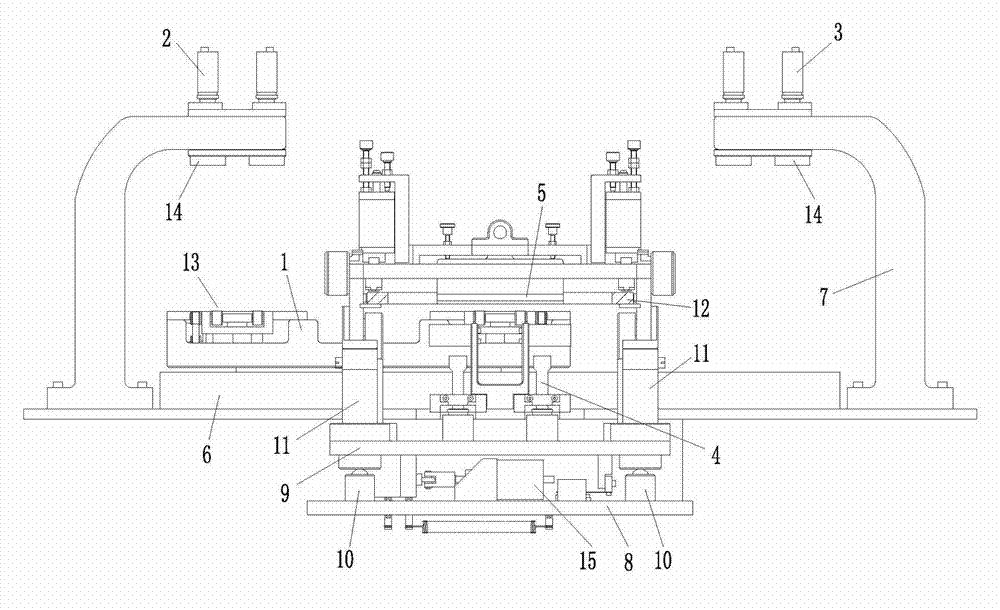

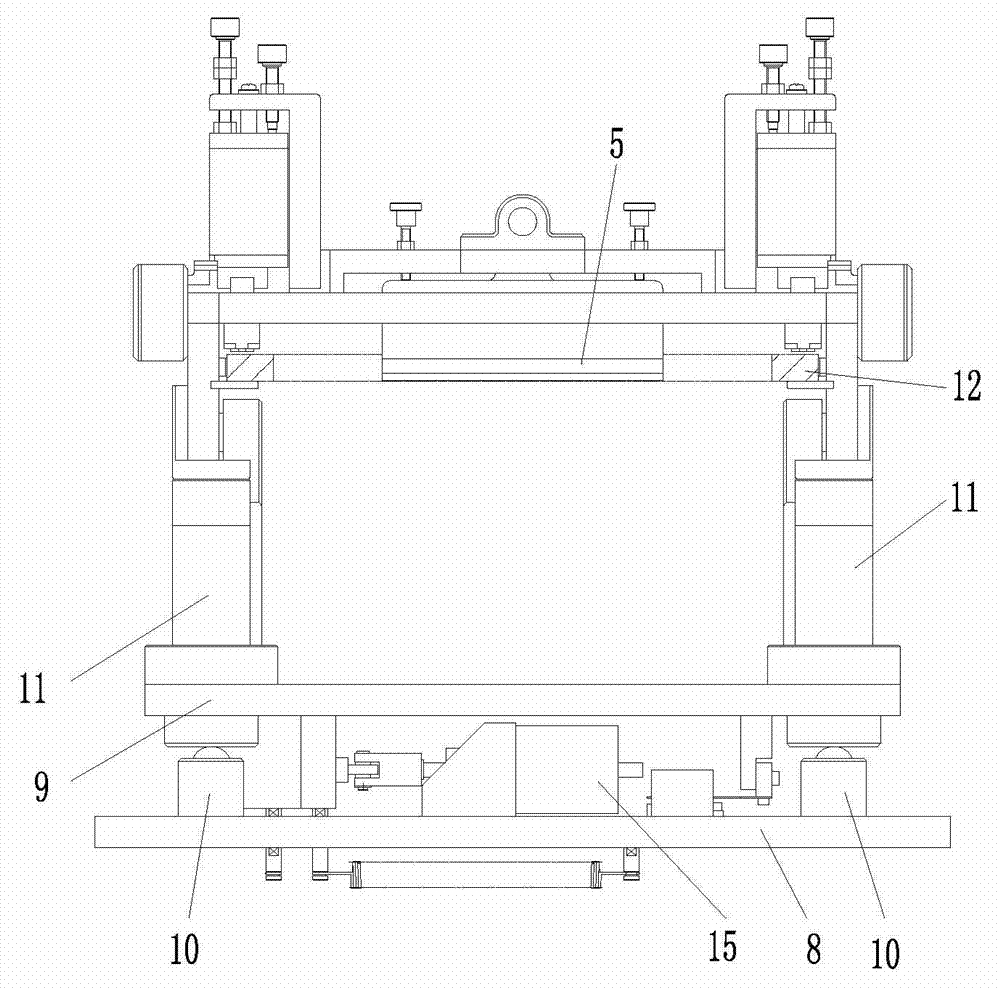

Pattern contraposition method based on double printing stations and device thereof

A double printing table and alignment device technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of silicon wafer grid line pattern offset or misalignment, overcome size and shape errors, ensure high quality, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

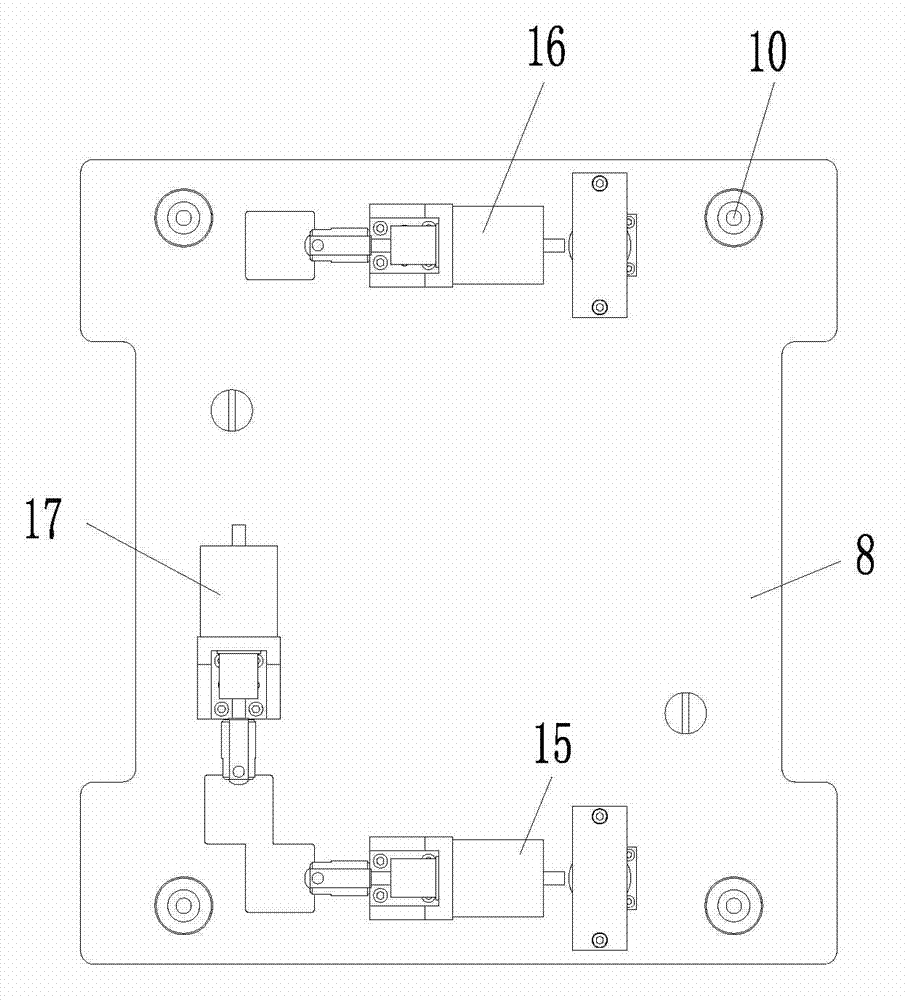

Embodiment Construction

[0020] The present invention discloses a kind of pattern alignment method based on double printing station, refer to Figure 4 , the method includes the following steps: (a) printing three discrete reference points on the first printed substrate, preparing three discrete reference points on the screen used in overprinting; the locations of the fiducial points are on the substrate Discrete separation, in order to improve the alignment accuracy of future overprinting; (b) In the subsequent overprinting, use the left camera to take pictures of the three reference points on the substrate transmitted to the left delivery station, and the obtained The positions of the three marks plus the distance from the left delivery station to the middle printing station are set as the reference coordinate system; since the present invention is based on double printing stations, the middle of the equipment is the printing station, and the right side also has the sending station. When the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com