Machining method for large double-layer thin-walled D-shaped section vacuum chamber fan-shaped section end face

An end face processing and vacuum chamber technology, applied in the field of machining of nickel-based alloy double-layer thin-walled structural parts, can solve the problems of wrinkles, double-layered thin-walled parts twisting, out-of-tolerance end surface flatness, etc., to increase the contact area , the effect of reducing deformation and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with examples. The implementation example is only an illustration of the invention, not a limitation of the invention. The steps not specifically described in the implementation example are all prior art, and will not be described in detail here.

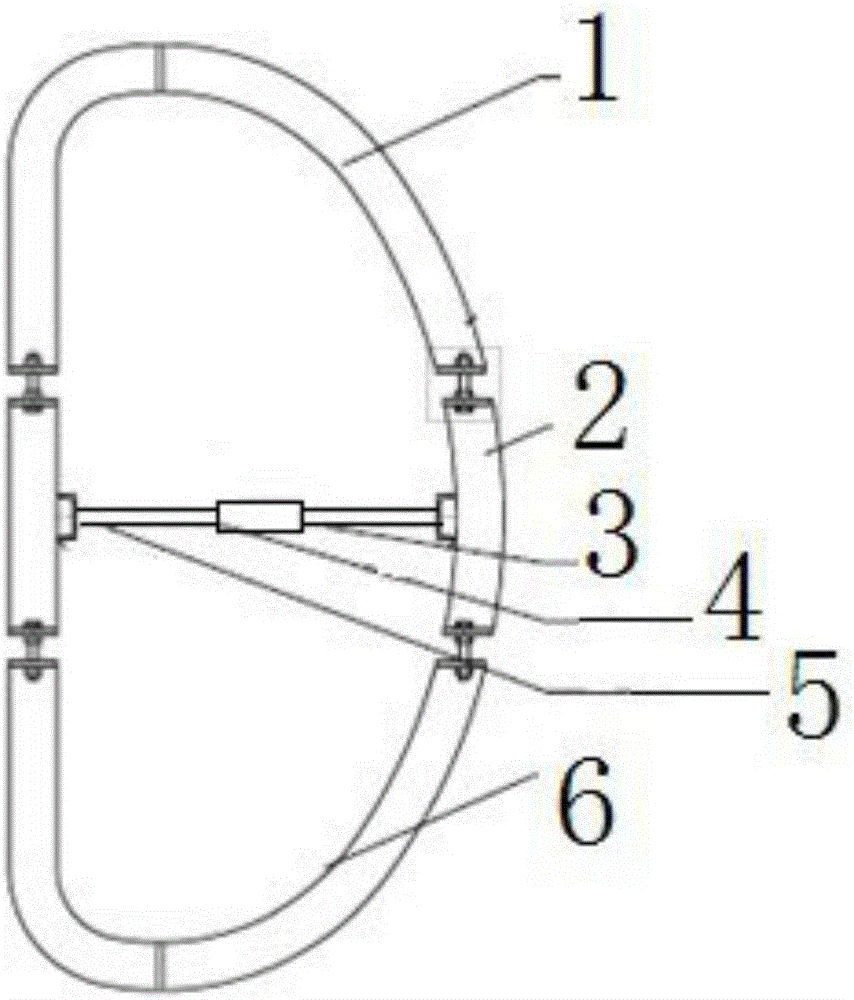

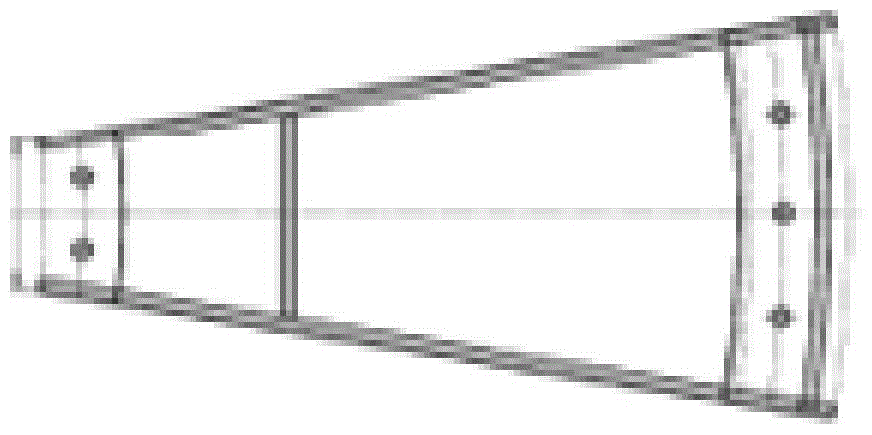

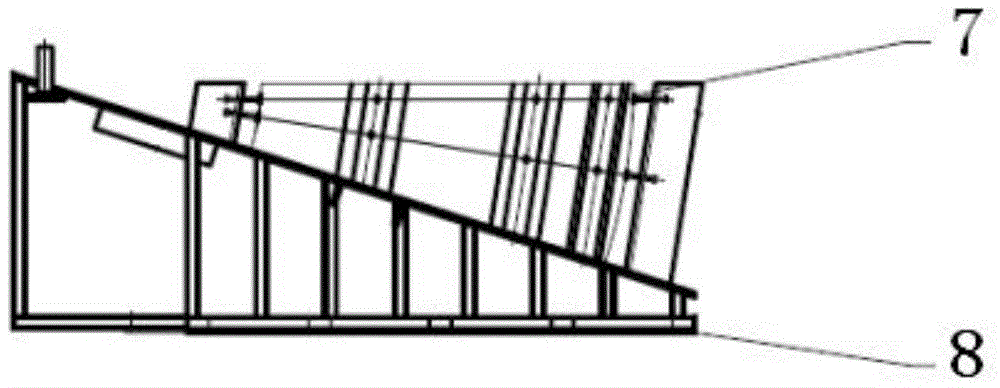

[0054] The invention discloses a method for processing the end face of a segment of a large-scale double-layer thin-walled D-shaped cross-section vacuum chamber. The large-scale double-layer thin-walled D-shaped cross-section vacuum chamber segment involved in the method is used to manufacture the vacuum of the main part in a magnetic confinement thermonuclear fusion device. The vacuum chamber is composed of 20 D-shaped cross-section vacuum chamber segments, and the 20 segments form a complete ring. Each D-shaped cross-section vacuum chamber segment is a space double-layer hyperboloid thin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com