Special die for assembling tower legs of iron tower

A technology of steel towers and molds, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of inability to assemble different types of tower feet, assembly quality and assembly efficiency, and inability to freely adjust the assembly angle of workpieces, so as to save assembly personnel, The effect of high reliability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

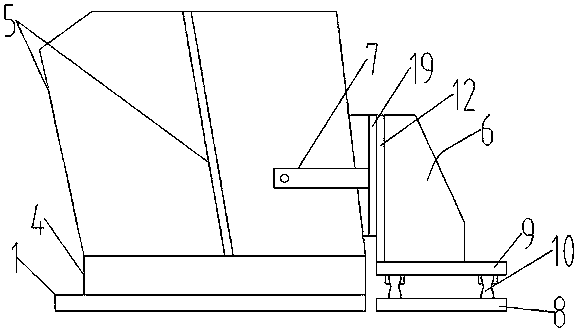

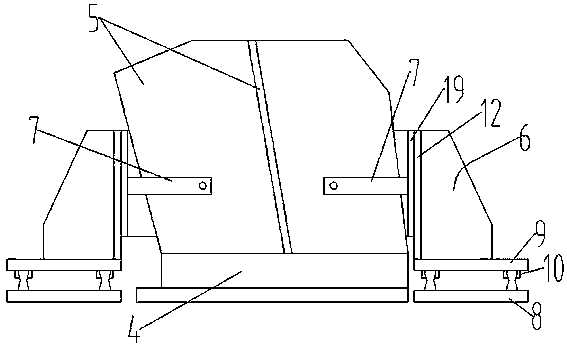

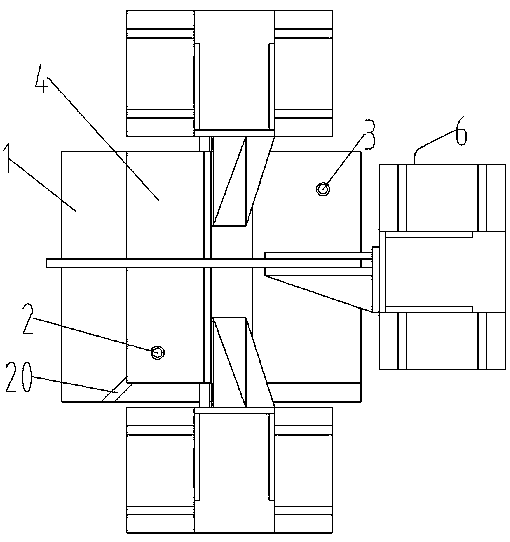

[0041] Example: such as Figure 1-3 As shown, a special mold for assembling the tower foot of an iron tower includes a tower foot base fixing plate 1, and the tower foot base fixing plate 1 is provided with a tower foot bottom plate positioning assembly for positioning the tower foot bottom plate 4, and the tower foot The outer side of the base fixing plate 1 is provided with multiple sets of three-dimensionally adjustable tower foot riser assembly molds 6 for clamping the tower foot riser 5 and positioning the tower foot riser 5 .

[0042] The overall structure of the tower foot base fixing plate 1 is rectangular, and the upper end surface of the tower foot base fixing plate 1 is obliquely provided with a chute 20 .

[0043]The tower foot bottom plate positioning assembly includes a main tower foot bottom plate main positioning member 3 fixedly arranged above the tower foot base fixed plate 1 and at an included angle of the tower foot base fixed plate 1, and a tower foot bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com