Method and equipment for providing vacuum heat insulation for solar system by negative pressure source

A technology of vacuum heat insulation and negative pressure source, applied in solar heating systems, solar thermal energy, solar thermal collectors using working fluid, etc. Expand the selection of materials and processes, and achieve good thermal insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

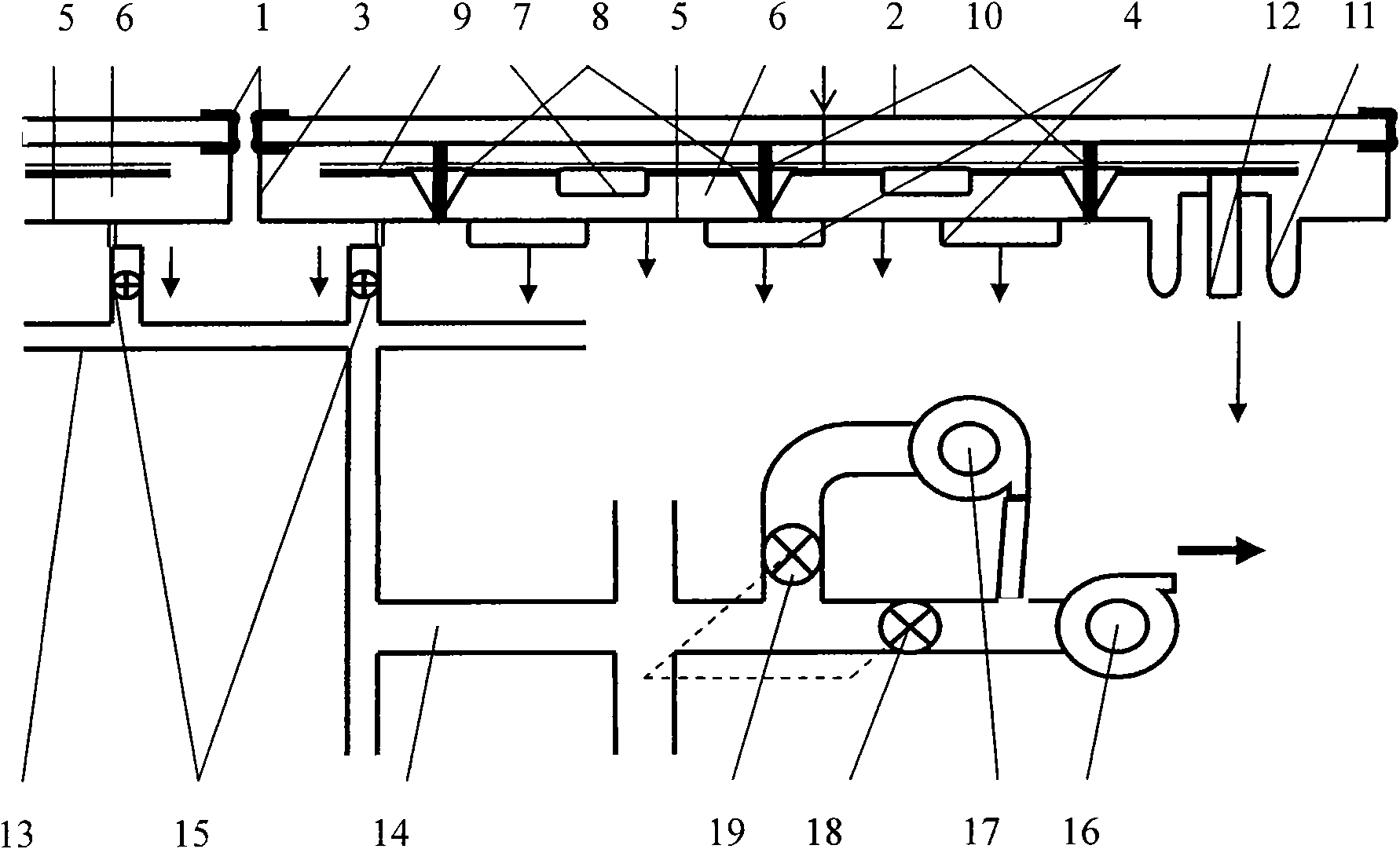

Method used

Image

Examples

Embodiment Construction

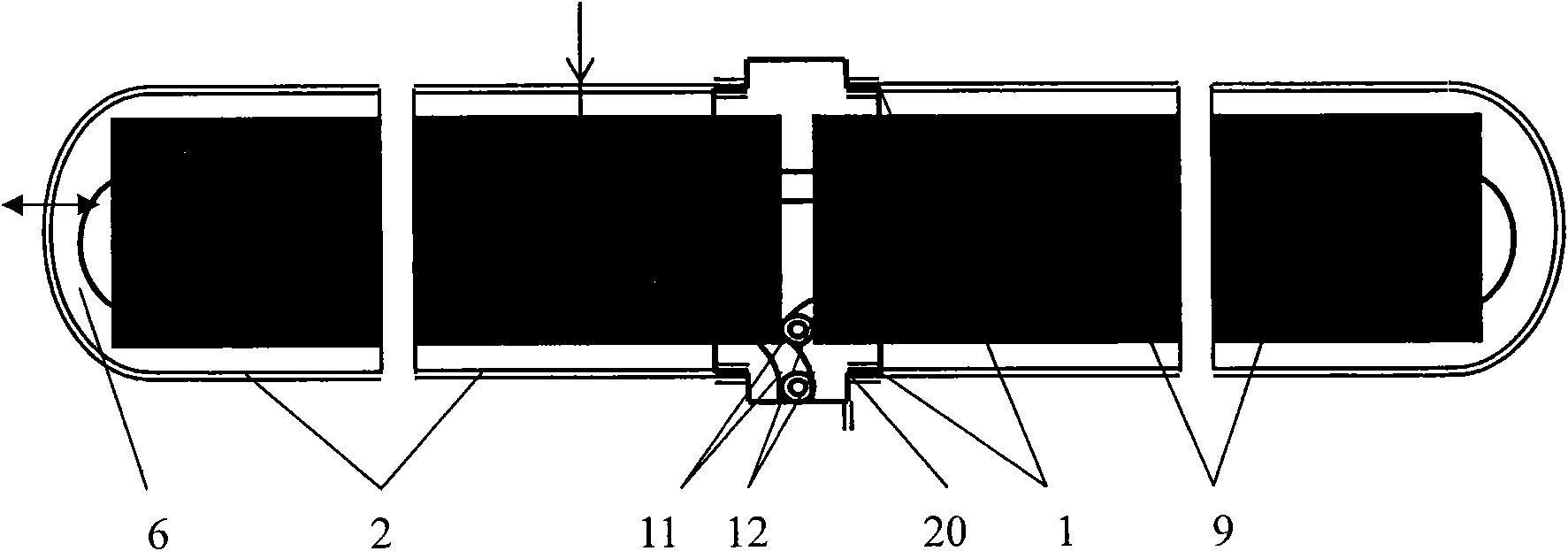

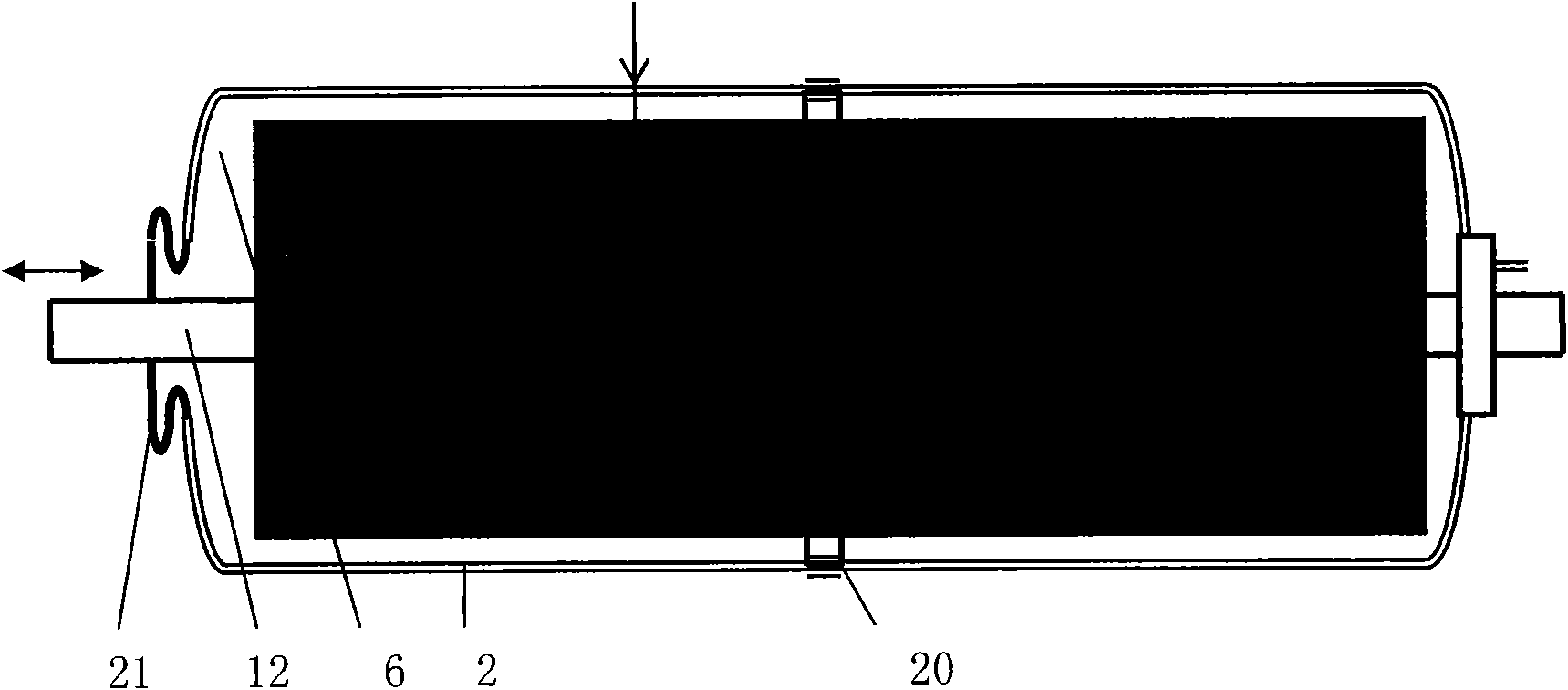

[0014] figure 1 Among them, a flat transparent body 2 bonded with an aluminum sheath 1 with a U-shaped cross-section and a shell 5 integrally manufactured with the frame 3 and the condenser 4 are bonded and sealed to form an integrated light-transmitting enclosure container6. The light-transmitting closed container 6 contains an absorber 9 which is manufactured integrally with the evaporator 7 and has many small holes 8 . Between the permeable body 2 and the housing 5, many supports 10 passing through the small holes 8 of the absorber 9 are used to support against negative pressure. The support 10 is not in contact with the pores 8 of the absorbent body 9 .

[0015] The light-transmitting closed container 6 adopts a recessed heat-insulation sleeve 11 to reduce heat loss at the junction of the inlet and outlet water barges 12 . The inner end of the heat insulating sleeve 11 is sealed and connected to the barge 12 , and the barge 12 passes through and protrudes from the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com