Plastic liner wound cylinder and manufacturing process

A technology for wrapping gas cylinders and inner liner, which is applied in the construction details of ships, fixed-capacity gas storage tanks, installation devices of container structures, etc., can solve the problems of leakage and insufficient sealing reliability of the bottle mouth, etc. High performance, not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

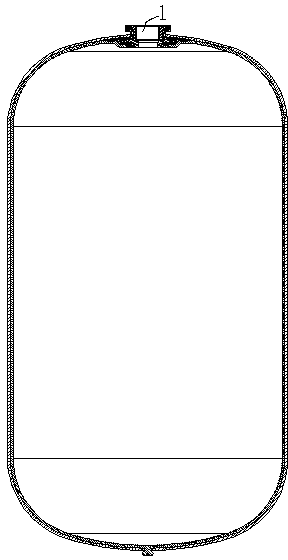

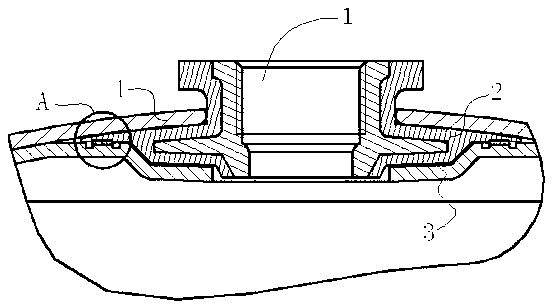

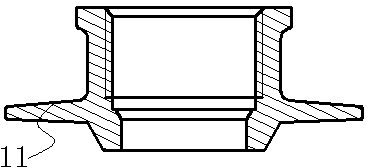

[0020] Attached below Figure 1-5 The present invention is described in further detail with the specific embodiment:

[0021] The plastic liner wraps the gas cylinder, including the bottle body and the bottle mouth. The bottle mouth includes the metal bottle mouth 1. The metal bottle mouth 1 is equipped with an injection molded part 2. The vertical height of the metal bottle mouth 1 and the injection molded part 2 is the same. The metal bottle mouth 1 is provided with an annular boss 11 on the outer side of the bottom. The upper surface of the annular boss 11 is a downwardly inclined surface. The injection molded part 2 is in the shape of a ring, and the inner shape of the ring matches the outer shape of the metal bottle mouth 1. The top of the boss 11 is provided with an outer edge body 21, the upper surface of the outer edge body 21 is inclined downward, and the thickness of the outer edge body 21 gradually decreases to 3mm-20mm along with the radial outer edge, and the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com