Lifting-type cultivation net cage

A lifting type, cage technology, applied in the field of aquaculture cages, can solve the problems of lack of survival ability and incompatibility, and achieve the effect of simple structure, complete functions of cages, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

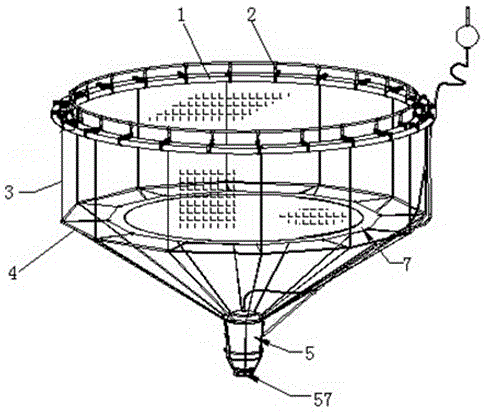

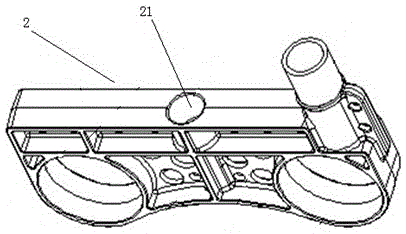

[0029] A lifting type culture net cage, comprising two floating tubes 1 and a floating tube support 2, the floating tubes 1 are connected together through the floating tube supports 2; also includes a plurality of vertical rigid suspension beams 3, a plurality of horizontal rigid beams 4. Gravity adjustment device 5 and anti-sway cloth 7; wherein, the top of the vertical rigid suspension beam 3 is connected to the floating pipe support 2, and the top of the top of the vertical rigid suspension beam 3 is provided with a spherical or hemispherical Hanging block 31, said floating pipe support 2 is provided with mounting hole 21, the bottom of said mounting hole 21 is an arc surface matched with spherical or hemispherical hanging block 31, and said vertical rigid suspension beam 3 is installed on the in hole 21. The bottom end of the vertical rigid suspension beam 3 is provided with a crossbeam corner joint 9, and the two ends of the horizontal rigid crossbeam 4 are fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com