Automatic wool top processing machine

A technology for processing machines and tops, applied in textiles and papermaking, etc., can solve problems such as low operation accuracy, low production efficiency, and high failure rate, and achieve the effects of low energy consumption, few accessories, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

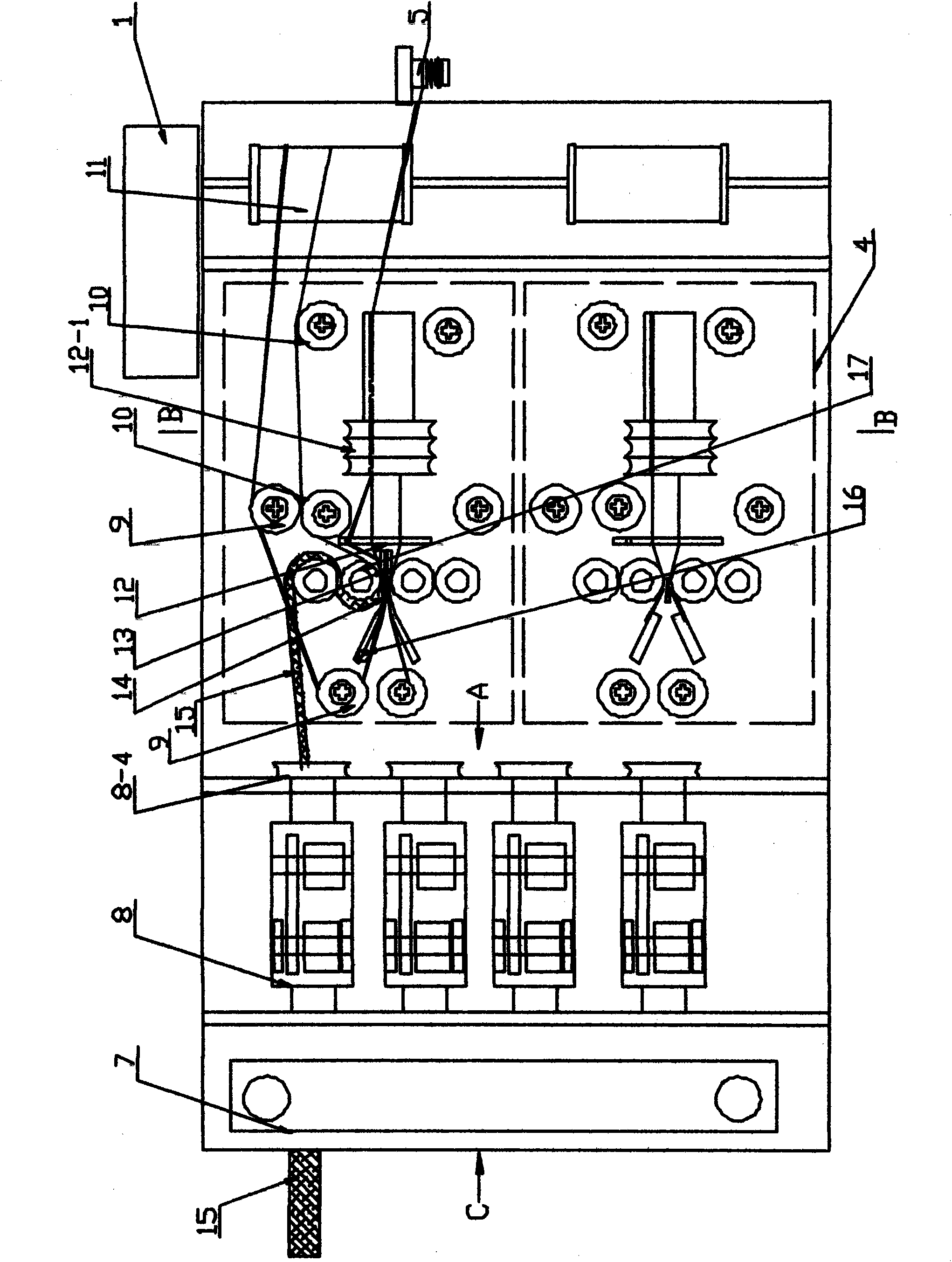

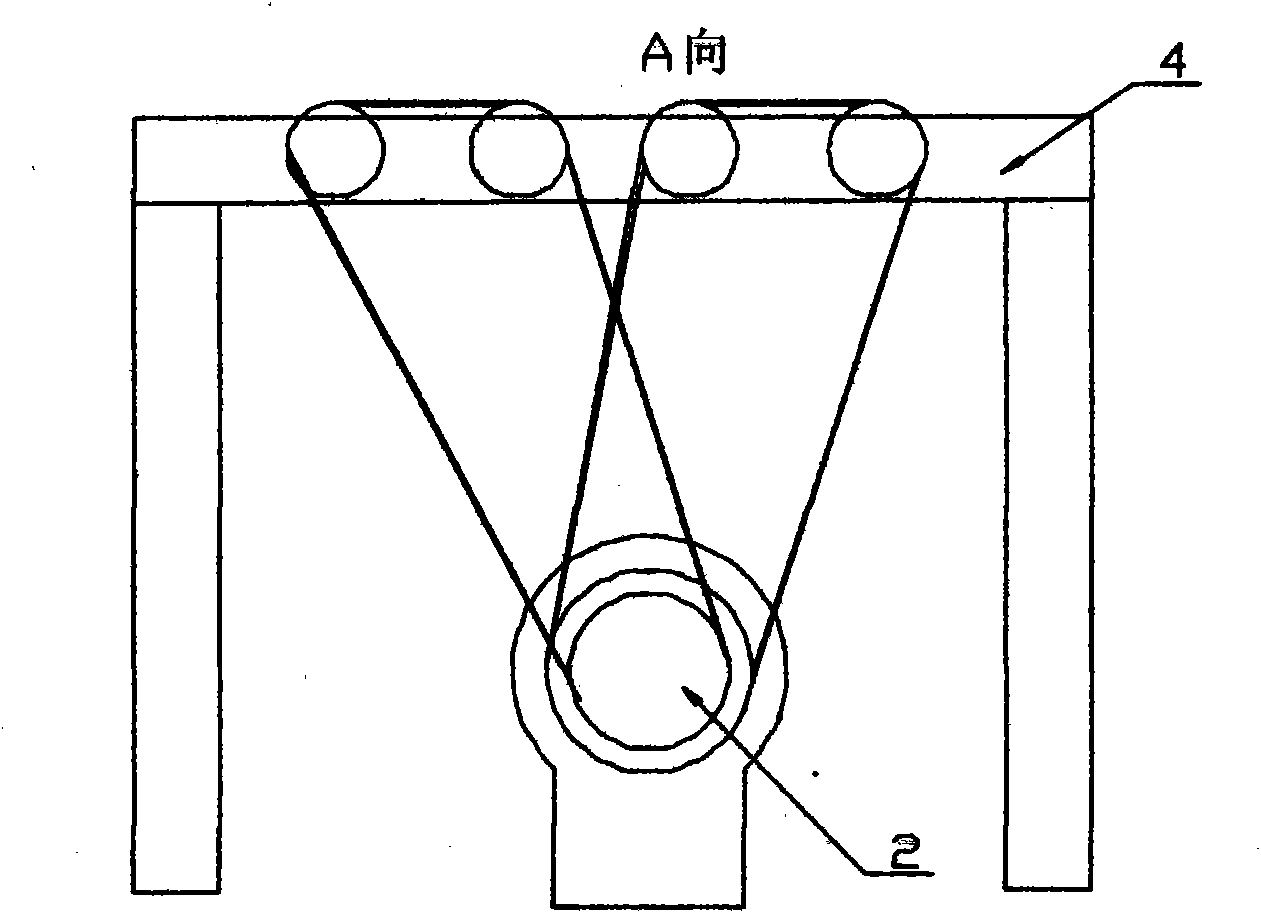

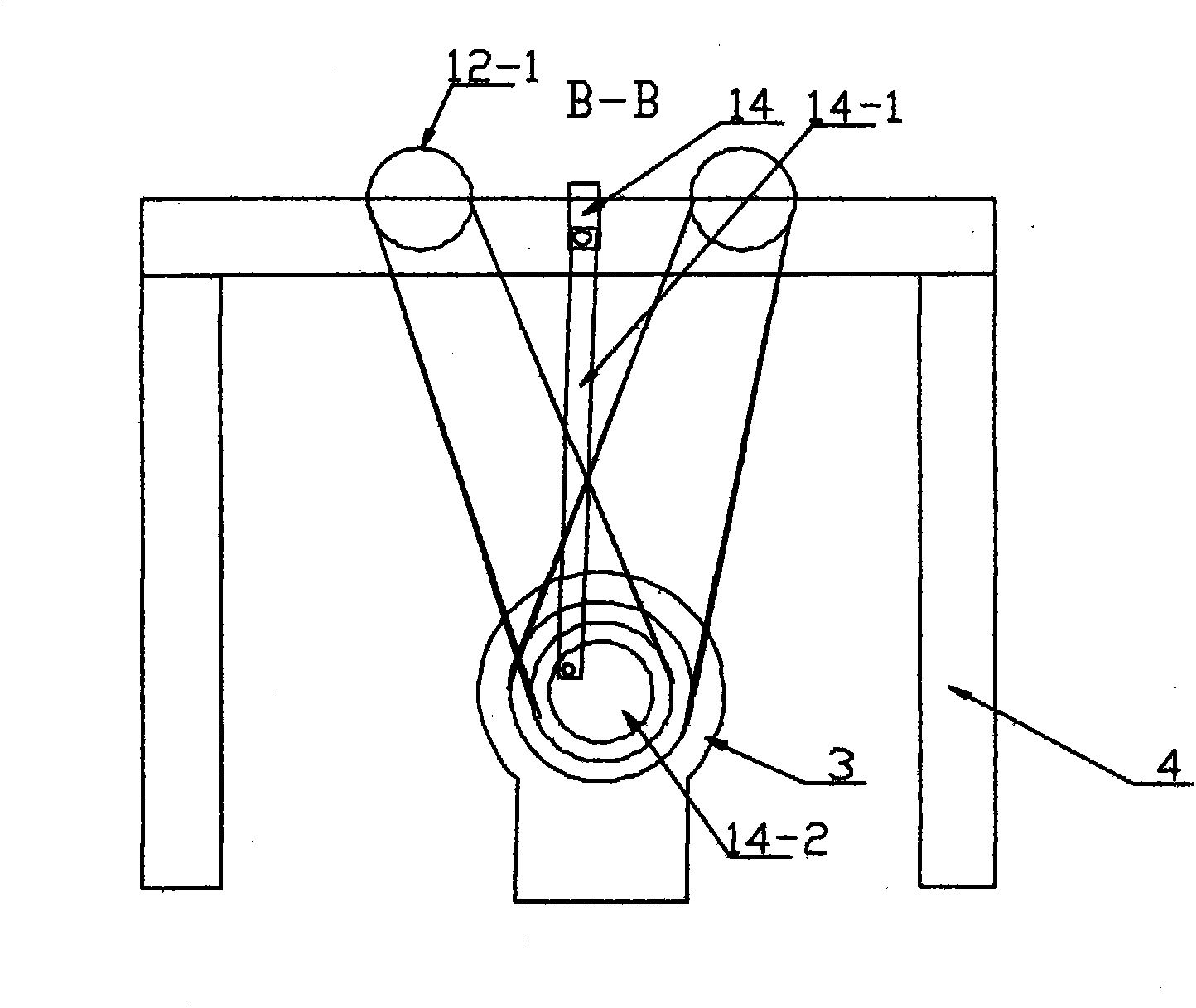

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

[0019] refer to Figure 1-Figure 6 , an automatic top processing machine, consisting of a body 4, and a power device installed on the body 4, a silk thread and an iron wire transmission device, a top processing device, a top rolling device, a top cutting device and a controller 1; the power device is installed on the body 4 Below, on the upper plane of the body 4, silk thread and iron wire conveying device, wool top processing device, wool top rolling device, and wool top cutting device are successively installed from right to left; Fault signal, alarm.

[0020] The power unit is composed of a first motor 2, a second motor 3, and a cylinder 6;

[0021] The silk thread and iron wire conveying device is used to convey the silk thread and iron wire of the top, and is composed of a thread wheel 5 and an iron wire winding drum 11. The silk w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com