Multi-focus laser laminated glass separating method and device

A laminated glass, multi-focus technology, applied in laser welding equipment, manufacturing tools, welding/welding/cutting items, etc., can solve the problems of difficult automatic cutting, reduce the dimensional accuracy and dimensional error of laminated glass, and improve the quality of cutting and separation , avoid the separation surface chipping, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

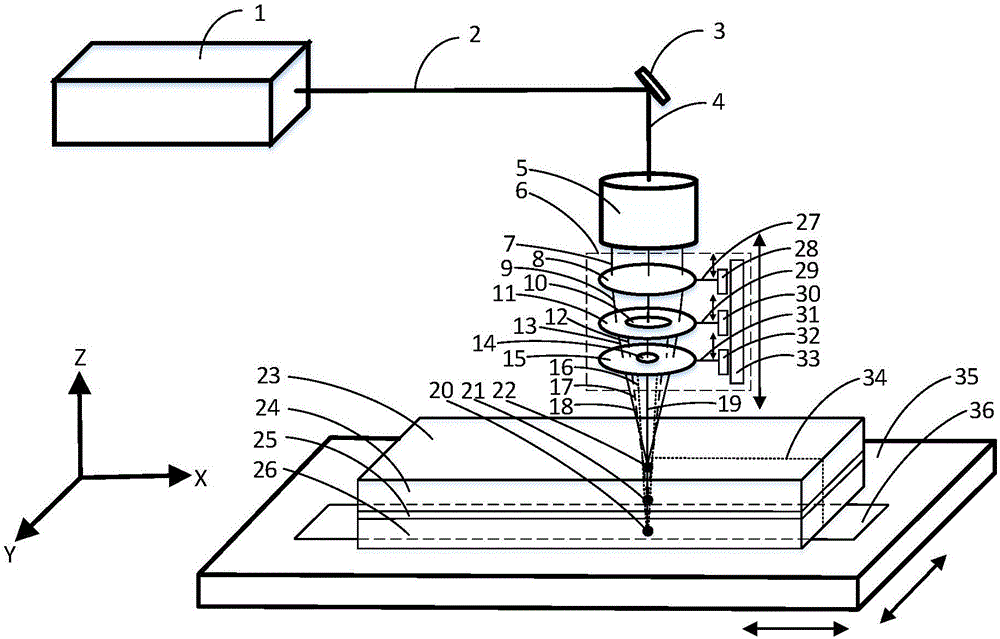

example 1

[0041] An ytterbium-doped fiber laser with an output wavelength of 1070nm is used, and the output peak laser power is 1000W. Pass the laser beam through the lens group to generate multiple focal points. The size of the separated laminated glass sample is 1000×1000mm, and the thickness is 10mm+10mm. 3-layer composite heat-insulating laminated glass for construction. Experimental method: using one of the specific implementations of multi-focus laser separation of laminated glass, adjusting the position and parameters of the laser focusing mirror to generate 3 focal points, and the distance between the focal points is 5mm. The second focal point is located at the center of the glued layer, the third focal point is located at the center of the outer glass of the lower layer of the laminated glass, and the energy distribution ratios of the first, second, and third focal points are 30%, 40%, and 30%, and the laser power is adjusted to 800W. The laser scanning speed is 1m / min, scanni...

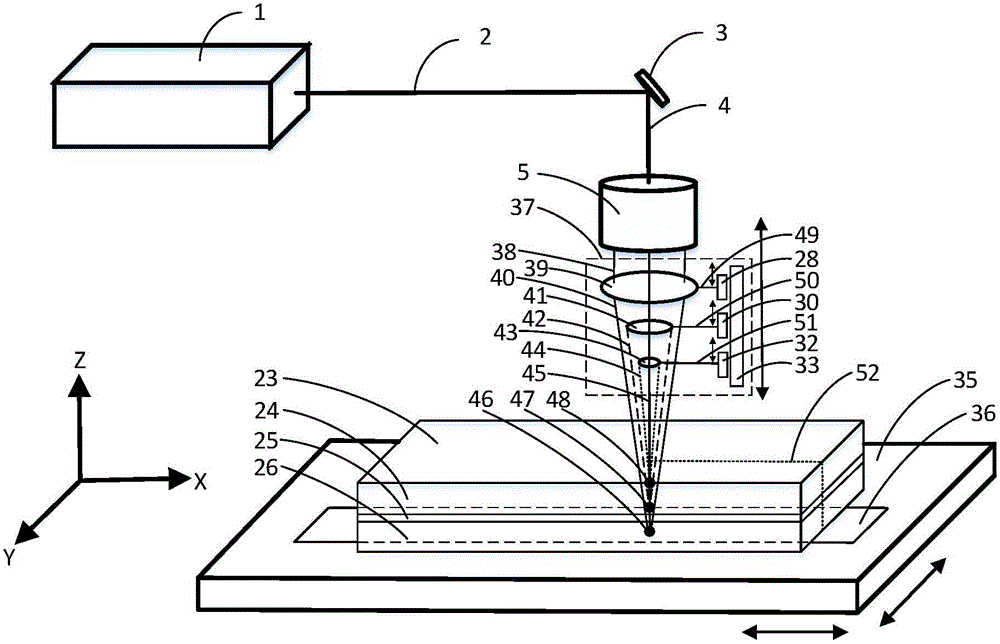

example 2

[0043] A Nd:YAG laser with an output wavelength of 1064nm is used, and the output peak power is 500W. The laser beam passes through the lens group to generate multiple focal points, and the separated laminated glass sample size is 1000×1000mm, and the thickness is 5mm+5mm. The three-layer composite sunscreen laminated glass for construction. Experimental method: Use multi-focus laser to separate laminated glass Specific implementation mode 2, adjust the position and parameters of the laser focusing mirror to generate 3 focal points, and the distance between the focal points is 2.5mm, and the position of the first focal point generated is located on the upper layer of the laminated glass. Center, the second focal point is located in the center of the interlayer, the third focal point is located in the center of the outer glass of the lower layer of the laminated glass, and the energy distribution of the first, second, and third focal points is 35%, 30%, and 35%, and the laser po...

example 3

[0045] An all-solid-state green laser with an output wavelength of 532nm is used, and the output peak power is 500W. The laser beam passes through the lens group to generate multiple focal points, and the separated laminated glass sample size is 500×500mm, and the thickness is 3mm+3mm 3-layer composite explosion-proof laminated glass for automobiles. Experimental method: using one of the specific implementations of multi-focus laser separation of laminated glass, adjusting the position and parameters of the laser focusing mirror to generate 3 focal points with a focal distance of 1.5mm, and the position of the first focal point generated is located on the upper layer of the laminated glass. Center, the second focus is located in the center of the interlayer, the third focus is located in the center of the outer glass of the lower layer of the laminated glass, and the energy distribution of the first, second, and third focus is 30%, 40%, and 30%, and the laser power is adjusted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com