Graphene film, and making method and use thereof

A graphene film and metal substrate technology, applied in the field of graphene film and its production method and use, can solve the problems of wasting raw materials, limiting the output of graphene film and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of graphene film of the present invention comprises the following steps:

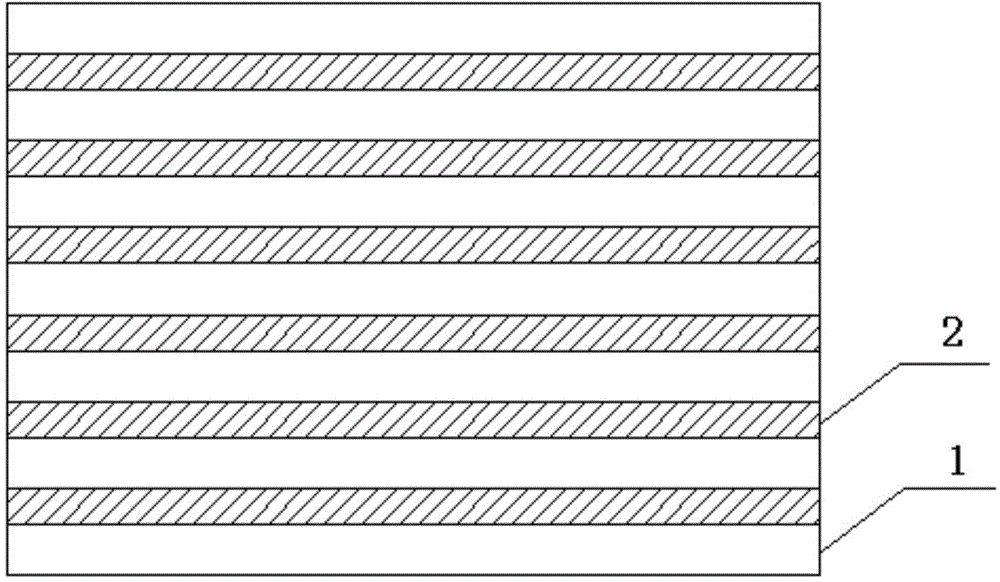

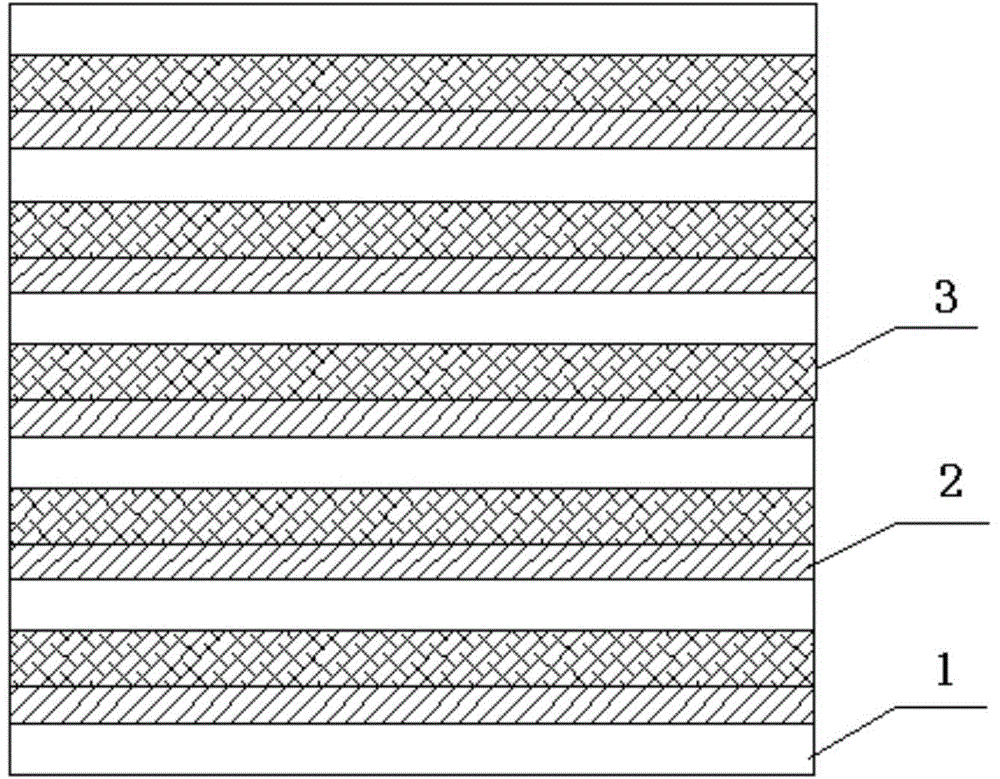

[0018] (1) Prepare a carrier for growing a graphene film, the carrier is a multi-layer separator-metal substrate structure formed by stacking separators and metal substrates at intervals;

[0019] (2) Place the carrier in a reaction furnace and heat it under vacuum or a mixture of inert gas and reducing gas;

[0020] (3) When the temperature reaches 900-1100°C, pass inert gas and reducing gas into the reaction furnace and heat-preserve and anneal, and then apply carbon source to form a graphene film on the metal substrate;

[0021] (4) Separate the separator from the metal substrate;

[0022] (5) Separate the graphene film from the metal substrate.

[0023] In a preferred embodiment of the method of the present invention, step (1) is implemented as follows: the spacer and the metal substrate are stacked at a distance of 10-100 μm, preferably 10-50 μm, more preferably 10-3...

Embodiment 1

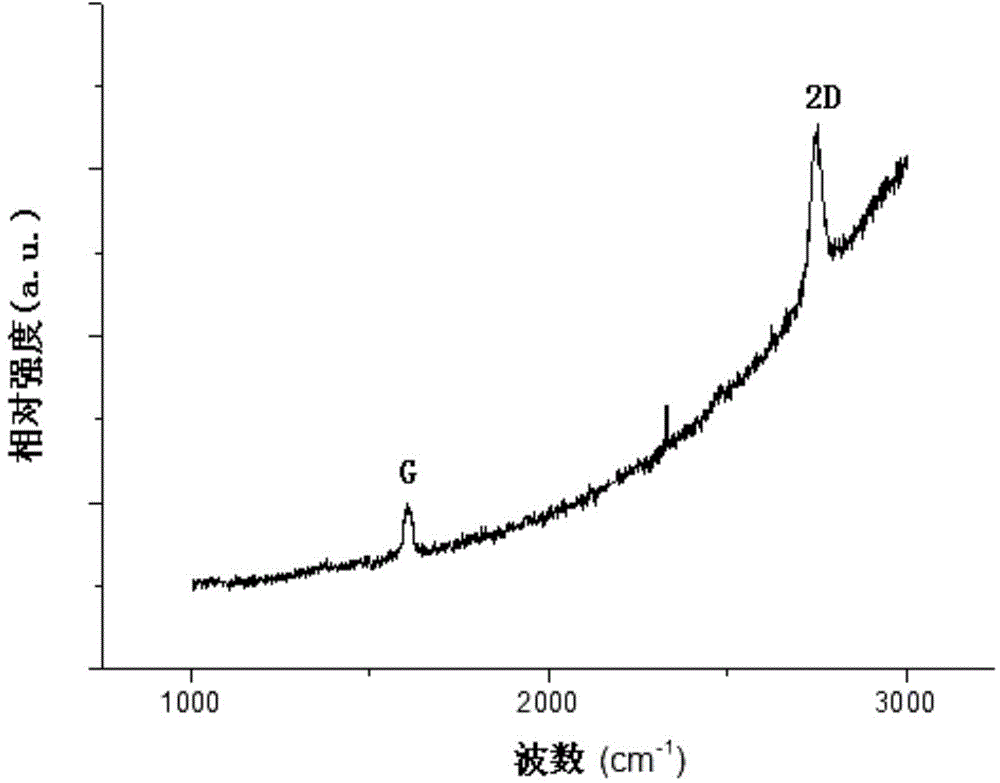

[0065] After the upper surface of the copper foil 2 (400x600x0.05mm) is polished, it is washed with deionized water and acetone in sequence, and then dried naturally. Then place the adjacent graphite plate 1 (400x600x0.1mm) and the copper foil 2 at an interval of 20 μm (the interval is realized with a square of graphite plate material), such as figure 1 The sequence shown is superimposed to form a 6-layer structured carrier. Put the prepared carrier into a 130L rectangular reaction furnace, seal the reaction furnace, and use a vacuum pump and a molecular pump to evacuate to 10 -3 Pa, then raise the temperature to 1000°C, feed hydrogen and argon at a flow rate of 20sccm (sccm refers to the flow rate in cubic centimeters per minute at 25°C and atmospheric pressure) and 500sccm, respectively, and keep warm for 30 minutes, then pass in at a flow rate of 200sccm Methane, stop the ventilation after 15 minutes and lower the temperature at 15°C / min. After cooling down to room temper...

Embodiment 2

[0069] After the upper surface of the nickel foil (400x600x0.05mm) was polished, it was washed with deionized water and acetone in sequence, and then dried naturally. Then adjacent graphite plates (400x600x0.1mm) and nickel foils are stacked sequentially at an interval of 25 μm (the interval is realized by a square of graphite plate material) to form a carrier with a 50-layer structure. Put the prepared carrier into a 130L rectangular reaction furnace, seal the reaction furnace, and use a vacuum pump and a molecular pump to evacuate to 10 -3 Pa, then raise the temperature to 1100°C, feed hydrogen and argon at flow rates of 20sccm and 500sccm respectively, keep warm for 30 minutes, then flow methane at a flow rate of 10sccm, stop ventilation after 30 minutes and cool down at 10°C / min. After cooling down to room temperature, the carrier was taken out, and the graphite plate was separated from the nickel foil using a jig to obtain a graphene film with nickel foil.

[0070] Apply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com