Continuous collection device for nanofibers spun through centrifugation and static electricity

A technology of nanofibers and collecting devices, which is applied in fiber processing, clustering of newly extruded filaments, textiles and papermaking, etc. It can solve problems such as inconsistent thickness of fiber cloth, and achieve the goals of avoiding cutting, high efficiency, and improving material utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

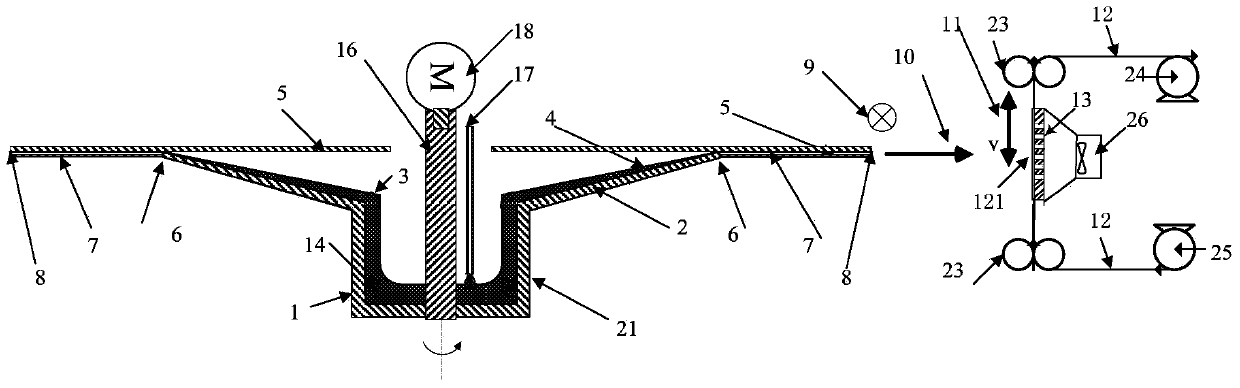

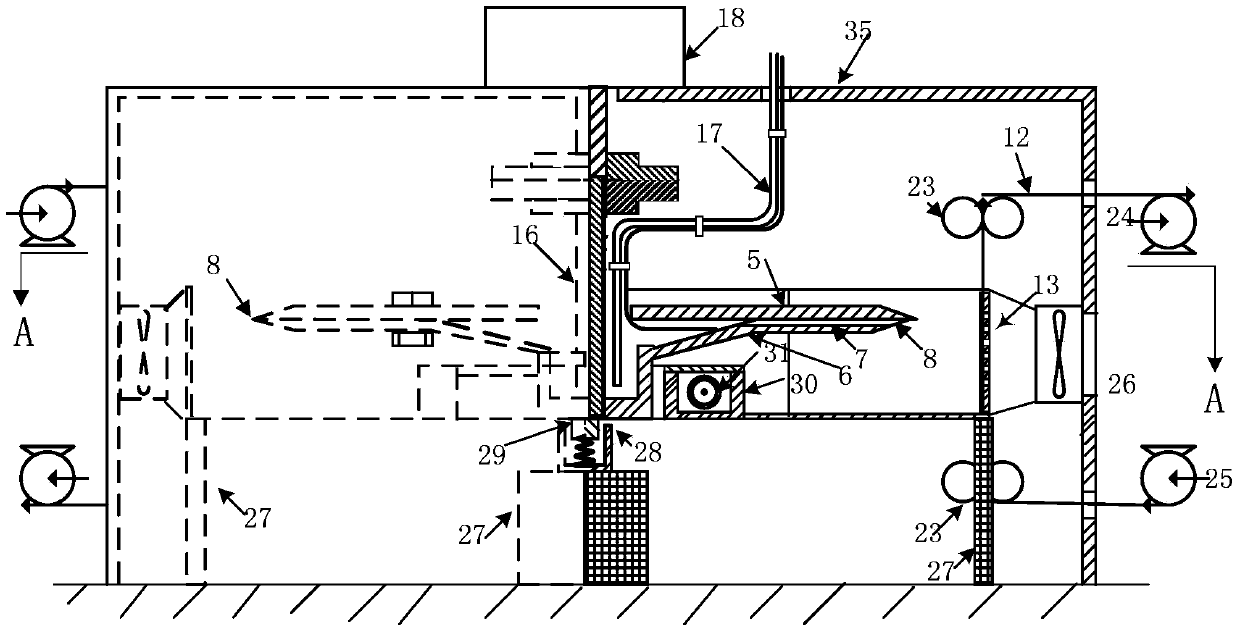

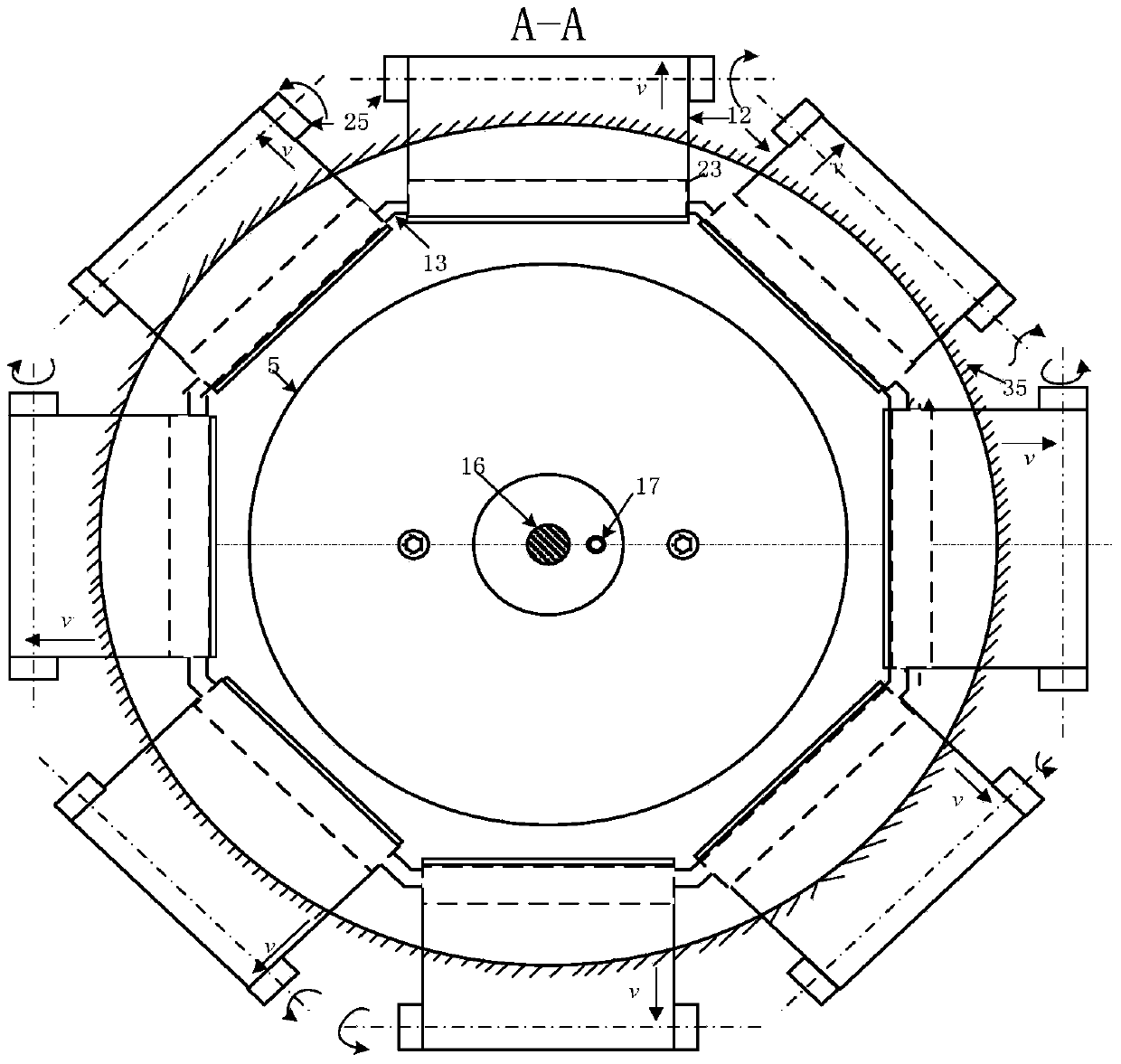

[0026] Example: Continuous collection devices for centrifugal electrospun nanofibers, such as figure 1 As shown, it includes several groups of collection mechanisms evenly distributed on the periphery of the spinning nanofiber mechanism, and each group of collection mechanisms includes a collection belt 12 driven by a transmission mechanism, and the collection belt 12 corresponds to the molten material outlet 8 on the spinning nanofiber mechanism. The position of the main collection part 121, the included angle between the plane where the main collection part is located and the rotation axis of the rotating cup 21 on the nanofiber spinning mechanism is a: 0≤a≤45 degrees. The plane where the collecting part 121 (moving direction is 11 ) is rotated on a line parallel to the tangent direction of the dissolving material outlet 8 to adjust the included angle a.

[0027] The centrifugal electrostatic continuous spinning nanofiber mechanism also includes an electrostatic Coulomb f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com