Cutting device for special outline of non-woven fabric and using method thereof

A non-woven fabric and cutting technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of inconvenient automatic assembly, high maintenance skill requirements, and high technical costs, so as to save labor costs, improve production efficiency, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

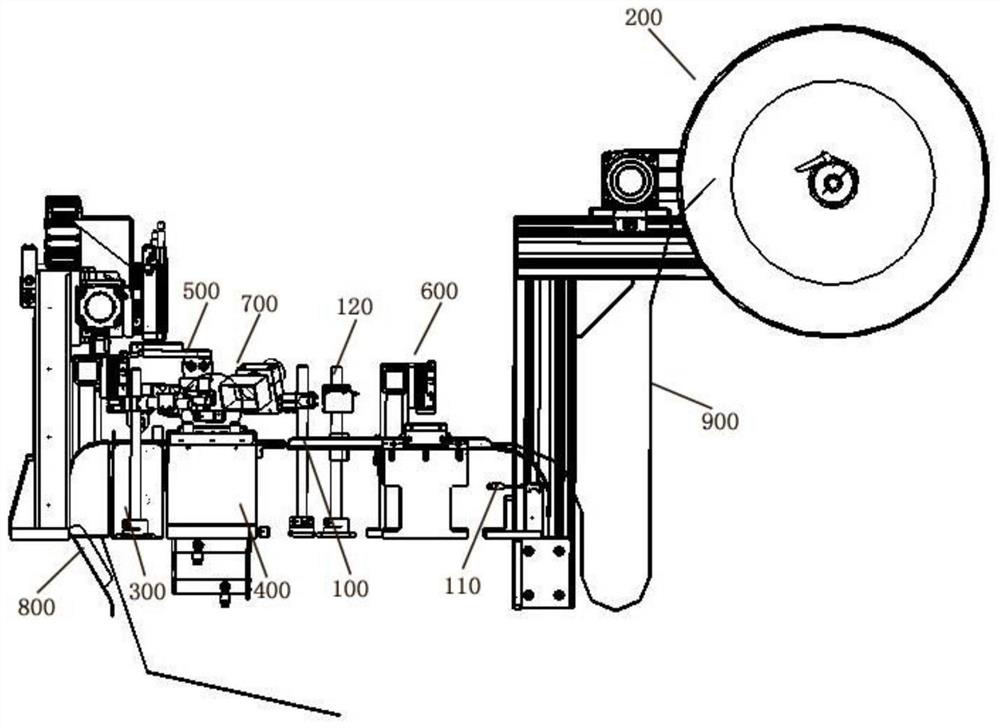

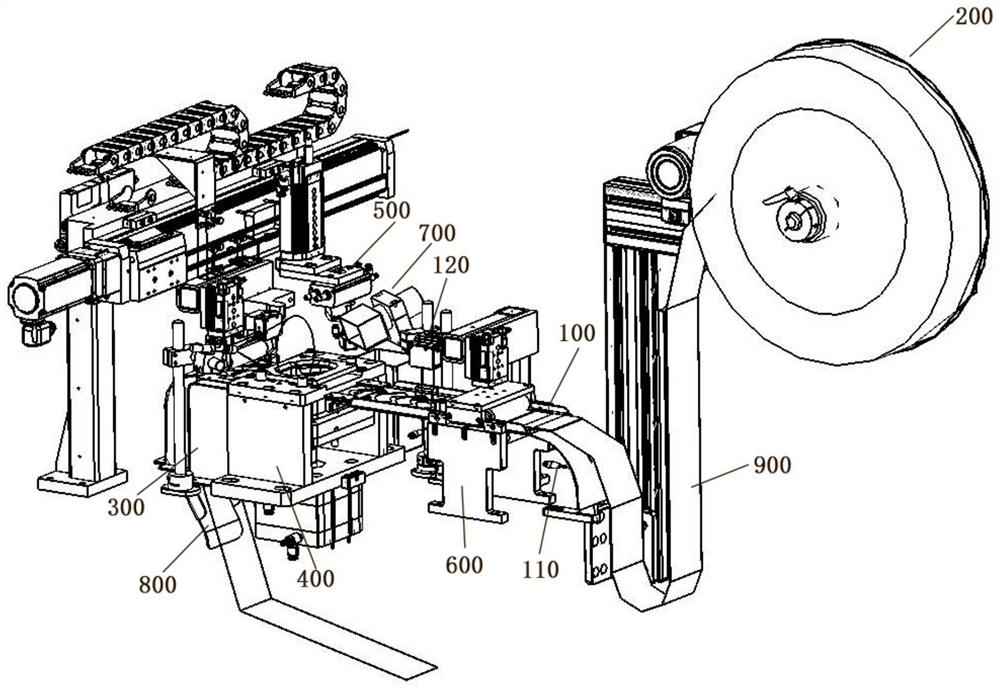

[0044] as attached figure 1 and 2 As shown, a cutting device with a special profile of non-woven fabrics includes a transmission frame 100 for carrying and transmitting non-woven fabrics 900, a feeding module 200 arranged on one side of the transmission frame 100, and a feeding module 200 arranged on the transmission frame 100. The drawing module 300 on the other side and away from the feeding module 200, the cutting module 400 for cutting the non-woven fabric 900 into a special profile, and the cutting module 400 for transferring the cut non-woven fabric 900 to the next station Reclaiming module 500.

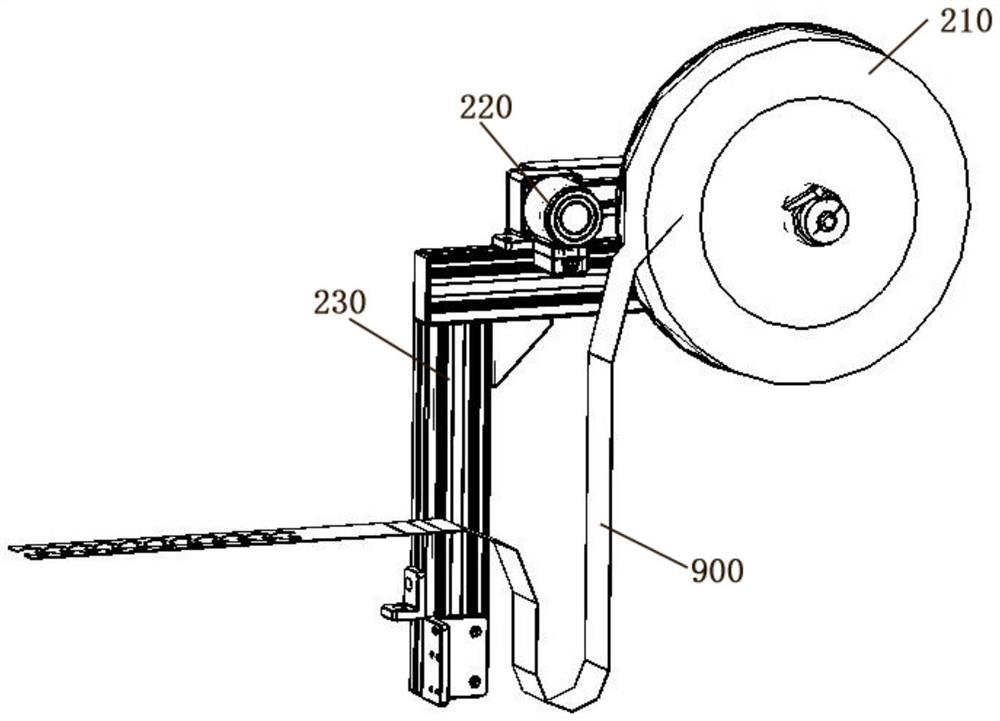

[0045] as attached image 3 As shown, the feeding module 200 is used to realize the discharging operation of the non-woven fabric 900. The feeding module 200 includes a reel disc 210 wrapped with a non-woven fabric 900 and a feeding assembly, and the feeding assembly drives the reel disc 210 rotation to realize the discharging operation.

[0046] The discharge assembly incl...

Embodiment 2

[0070] Based on the above-mentioned embodiment 1, a method for using a cutting device with a special profile of non-woven fabrics comprises the following steps:

[0071] 101. The feeding module 200 is unloading, and the unwinding component drives the reel disc 210 to rotate, so as to realize the non-woven fabric 900 unloading;

[0072] 102. One end of the non-woven fabric 900 passes through the transmission frame 100, is compressed by the pulling module 300, and the driving wheel 320 is driven by the pulling motor 310 to rotate, so as to realize the transmission of the non-woven fabric 900;

[0073] 103. The straightening module 600 flattens the curved non-woven fabric 900 through the upper roller 610 and the lower roller 620 at the feeding end of the transmission frame 100;

[0074] 104. The cutting module 400 cuts the non-woven fabric 900 transferred to the station, and the dust cleaning module 700 cleans the dust generated during the cutting process;

[0075] 105. The cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com