A sponge city permeable pavement suitable for prefabricated roadbed

A technology of sponge city and permeable pavement, which is applied to cohesive pavement paved on site, pavement details, roads and other directions, which can solve the problems of not meeting the functional requirements of the sponge city, inability to realize in-situ compensation of water flow, and low use intensity , to achieve recyclable utilization, solve the problem of insufficient stability, and reduce water accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific implementation cases of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these implementation cases.

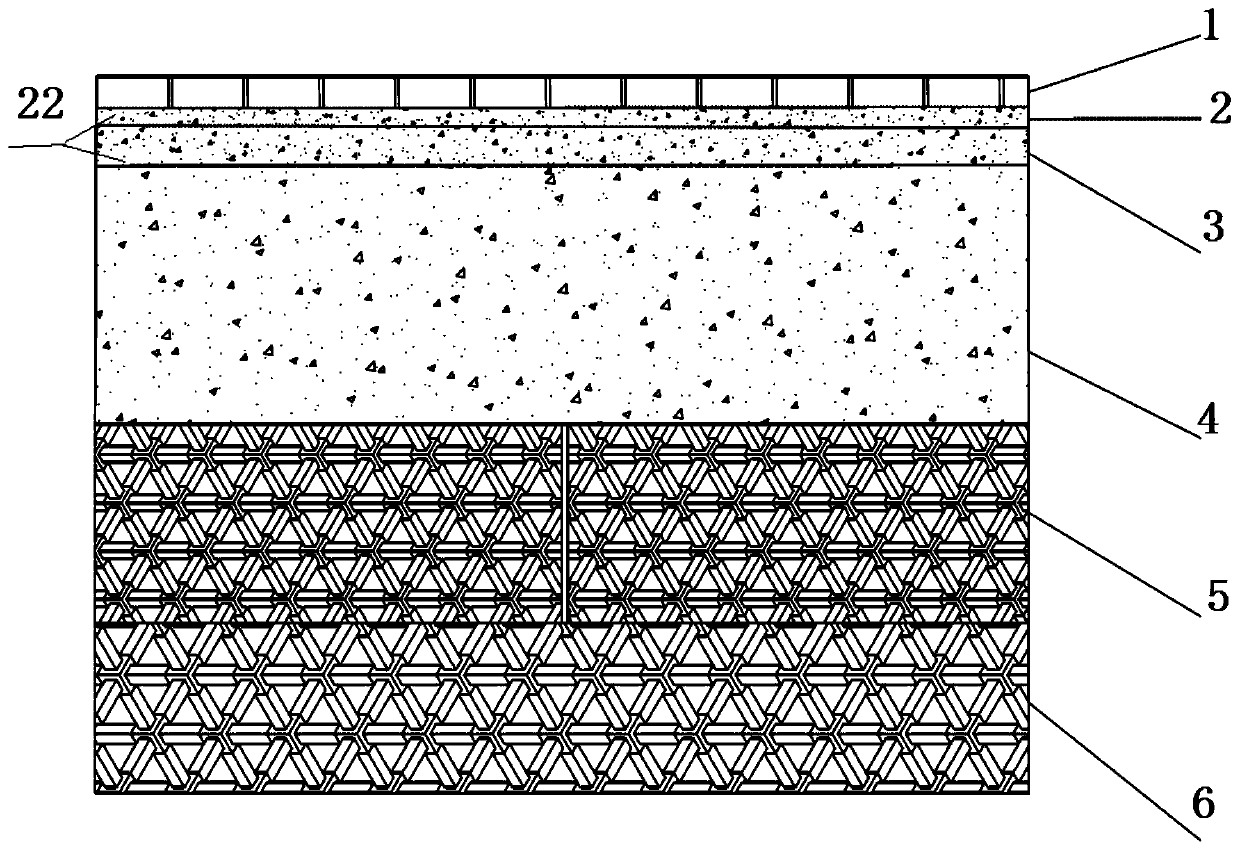

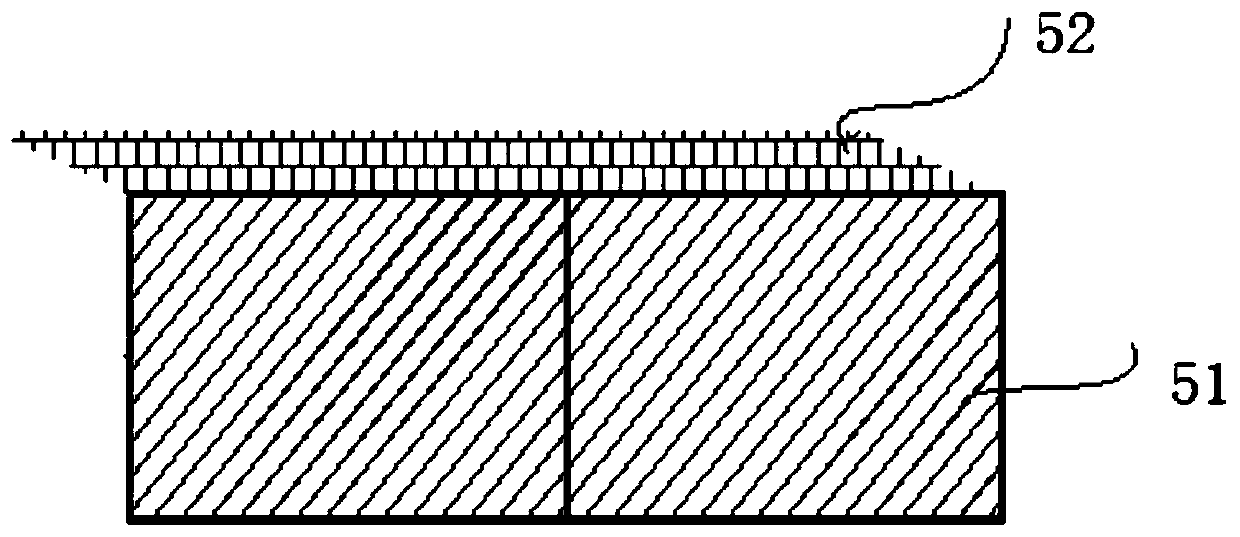

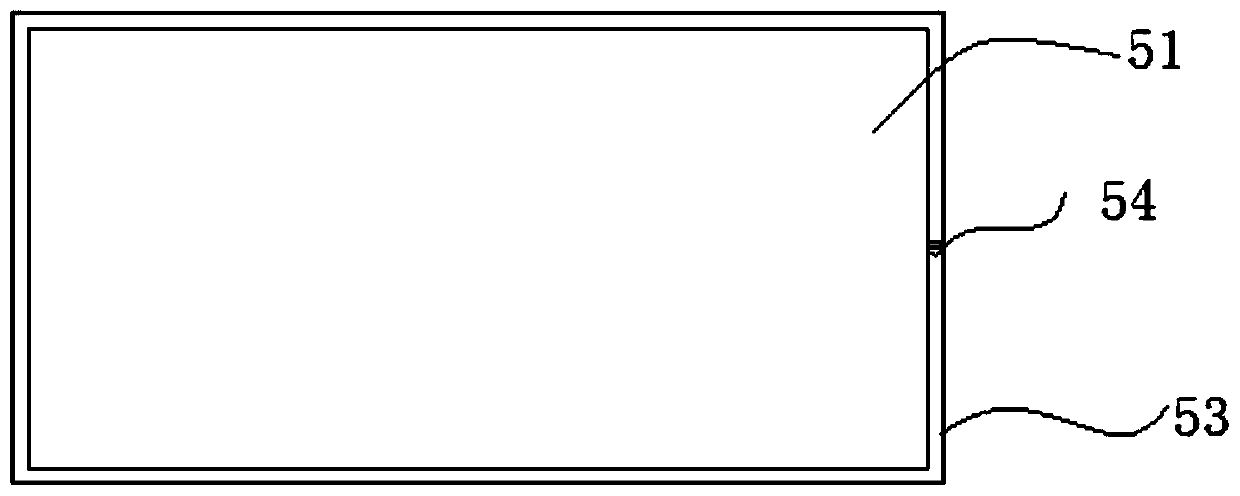

[0028] Such as figure 1 As shown, the present invention is applicable to the sponge city permeable pavement pavement of the prefabricated roadbed, which comprises a surface layer 1, a leveling layer 22, a base layer 4, a road base layer 5 and a soil base layer 6 from top to bottom, and the surface layer 1 is composed of a high-strength compact Composed of bricks; the leveling layer 22 and the base layer 4 are both composed of crushed stone structure layers; the road base 5 is composed of prefabricated and assembled roadbeds. When the pavement encounters natural rainfall, the water flows sequentially through the caulking of the surface layer 1, the porosity of the leveling layer 22 and the base 4, the caulking o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com