A method for subsequent filling of closed open field mining

A closed, empty field technology, applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of unsatisfactory filling effect, easy weathering of the upper part, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

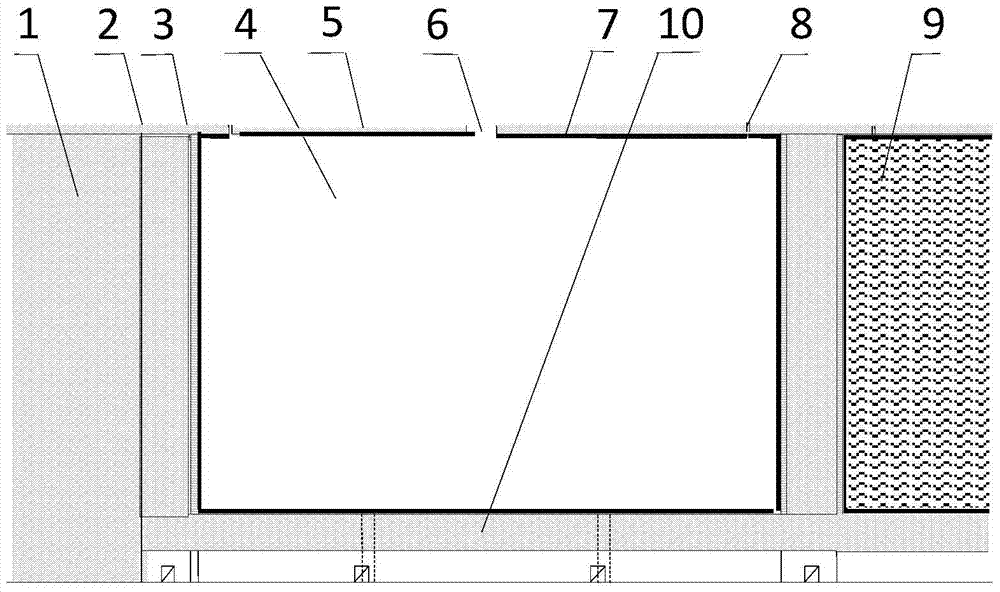

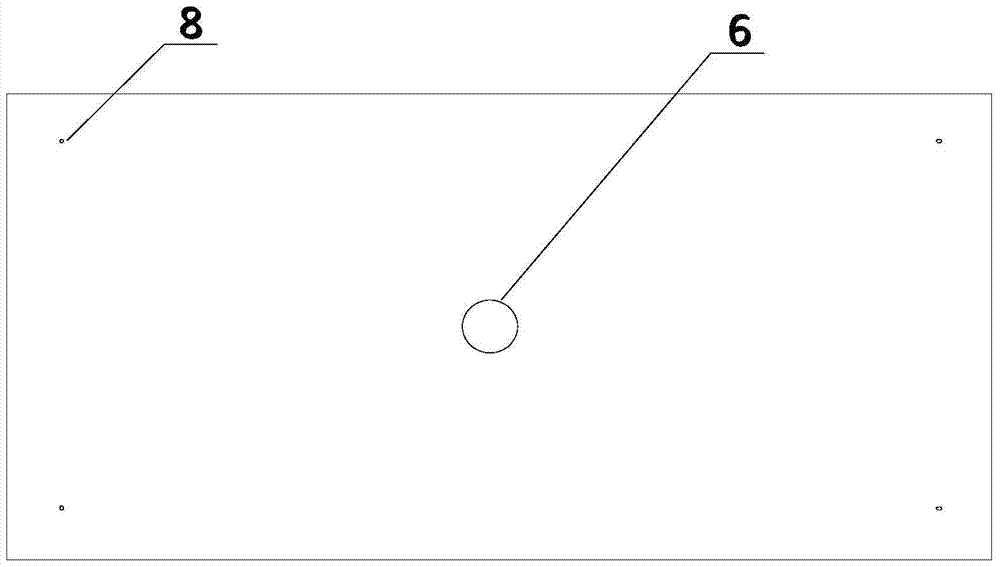

[0018] Further describe the present invention below in conjunction with accompanying drawing.

[0019] like figure 1 and figure 2 Shown, a kind of closed-type open-stop mining subsequent filling method, this method adopts the open-stop mining method to back-mining the mine house, and forms the open goaf, and it is characterized in that a filling patio 6 is excavated on the roof 5, and through filling The patio 6 lowers the filling material, lifts and transports equipment, materials, personnel and ventilation, utilizes a drilling rig to drill four exhaust holes 8 at the four corners of the top plate 5, builds a partition wall 3 around the goaf, and connects the bottom plate 10 and the top plate 5 The treatment is smooth, and the waterproof material 7 is laid on the partition wall 3, the bottom plate 10 and the roof 5 around the goaf, and the vent holes 8 and the filling well 6 are not pasted with waterproof materials. Closed filling space 4, inject the filling material into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com