Pressure filling device and method of molten metal

A technology of melting metal and pressure, applied in the direction of pressure vessels, pressure vessels/vacuum vessels used in chemical processes, etc., which can solve the problems of easy pollution and oxidation of metals, time-consuming and energy-consuming, pollution of people and the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

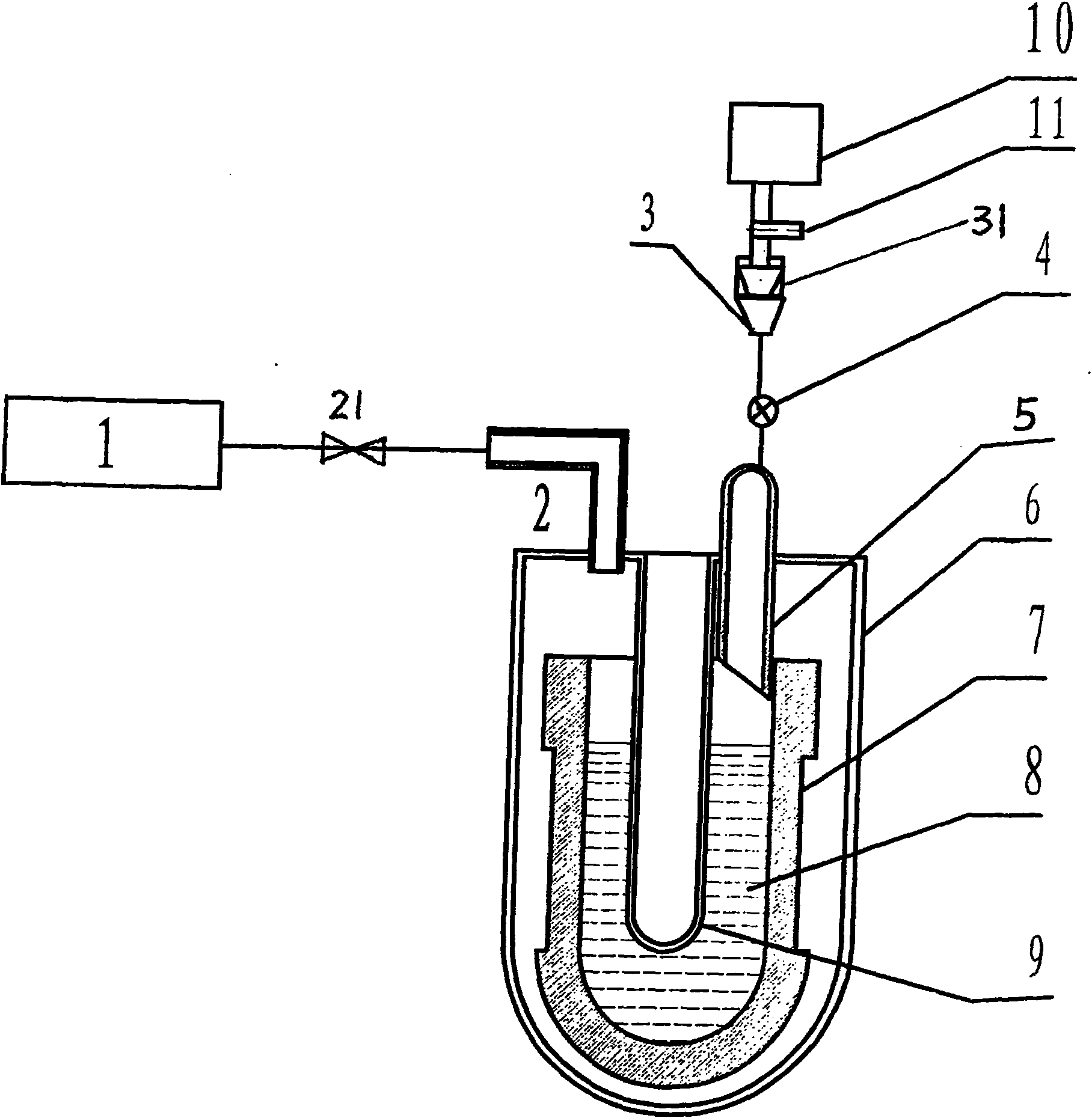

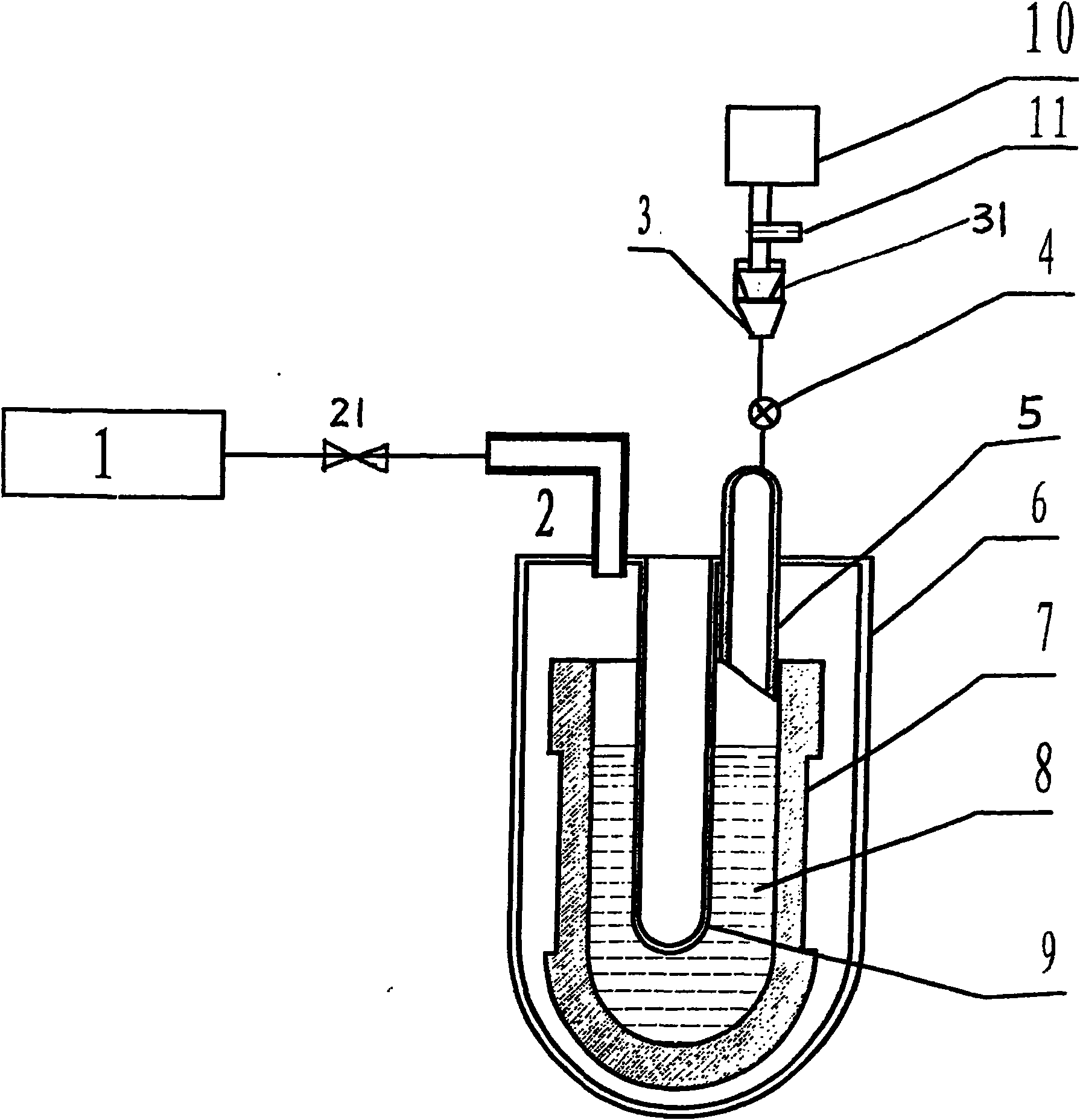

[0021] Below with regard to the step and the structure and the effect that can produce of the pressure filling device and method of molten metal of the present invention, cooperate accompanying drawing to describe in detail as follows with preferred embodiment:

[0022] First referring to Fig. 1, the pressure filling device for molten metal of the present invention includes: vacuum system 1, exhaust pipe 2, funnel 3, valve 4, liquid filling pipe 5, bulb 6 (made of glass or metal, The following description takes the glass bulb as an example), crucible 7, thermometer well 9 and air bag 10; wherein the glass bulb 6 is "U" shaped, and the U-shaped opening is the thermometer well 9; the crucible 7 is arranged in the glass bulb 6, and the crucible 7. The opening is upward, and the opening end is provided with a distance from the upper port of the U-shaped tube. The bottom of the crucible 7 is placed on the U-shaped bottom of the glass bulb 6; The other end of the tube is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com