Amphibious lng tank container reloading ship and reloading method

A technology for tank containers and hulls, applied in shipbuilding, ship fittings, ship parts, etc., can solve problems such as complex structure and unfavorable production, and achieve the effects of fast operation speed, high safety and efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

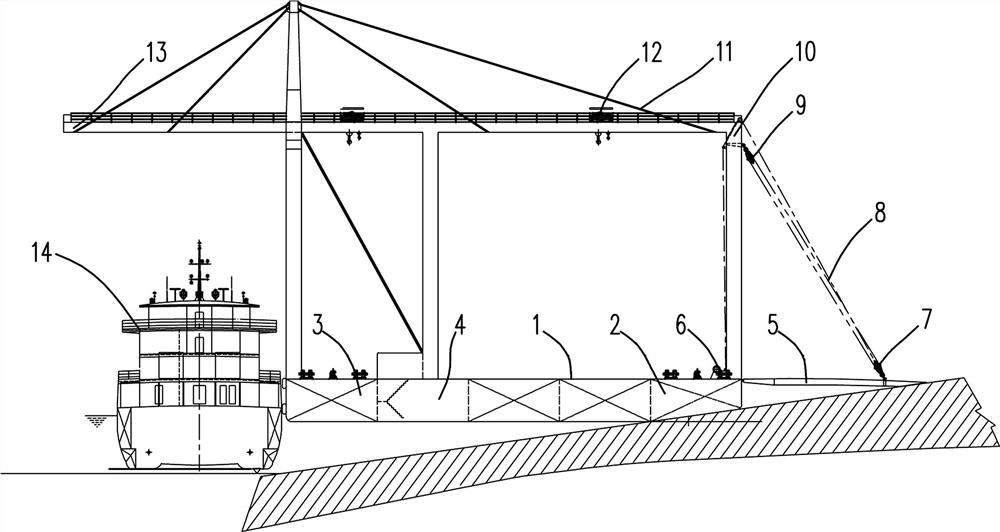

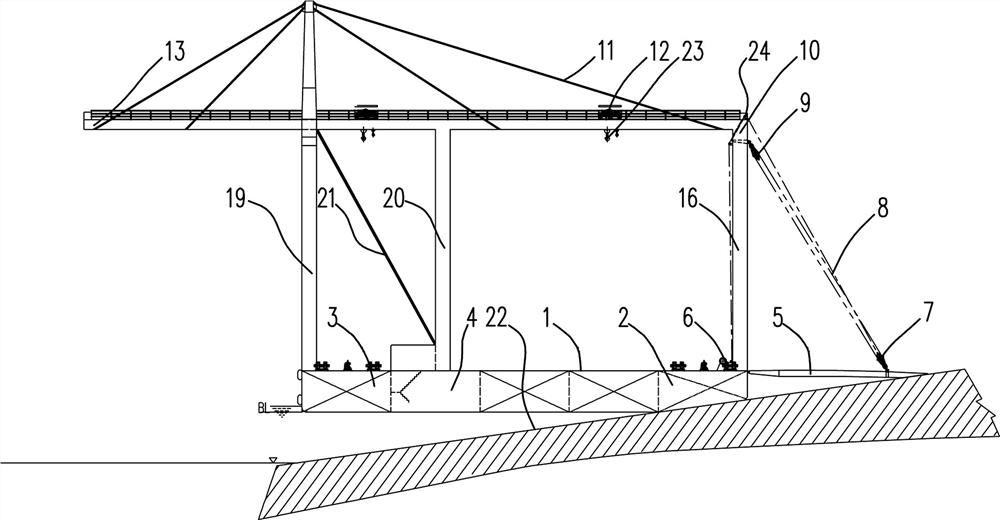

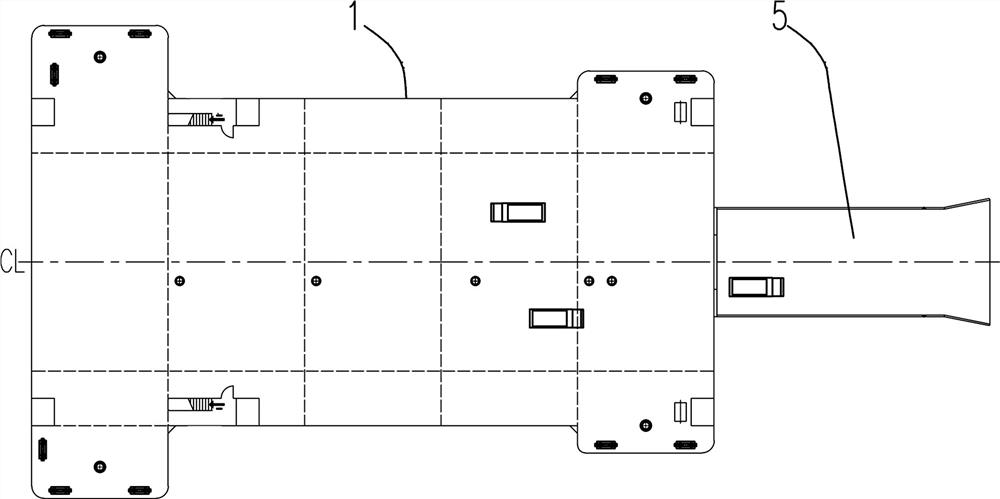

[0034] Such as Figure 2~5 Among them, an amphibious LNG reloading ship includes a hull 1, a hoisting device is arranged on the hull 1, a first ballast tank 2 is arranged at one end of the hull 1, and there are two first ballast tanks 2, and two ballast tanks at the bow of the hull One is arranged on each side, and the bottom of the first ballast tank 2 is provided with an inclined surface in contact with the ramp lane 22. Preferably, the inclination of the ramp lane 22 is 8°, and the inclined surface at the bottom of the first ballast tank 2 is also 8° accordingly. A wear-resistant material, such as rubber, is provided at the position of the slope. There is also a pump room 4 for adjusting the load in the first ballast tank 2;

[0035] An end of the hull 1 close to the first ballast tank 2 is provided with a driving ramp 5, preferably, the driving ramp 5 adopts a retractable structure. With this structure, by adjusting the load water in the first ballast tank 2, the hull 1 ...

Embodiment 2

[0045] On the basis of Example 1, such as figure 1 Among them, a method for reloading using the above-mentioned amphibious LNG reloading ship, comprising the following steps:

[0046] S1. Pull the hull 1 to the appropriate position of the ramp lane 22, and increase the load by injecting water into the first ballast tank 2 through the pump room 4, so that the bottom of the first ballast tank 2 is in contact with the ramp lane 22; The position close to the land base is towed by a cable, one end of the cable is connected to the electric winch installed at the tail of the hull 1, and the other end is connected to the ground cow on the slope lane 22, and the position of the hull 1 is realized by tightening or loosening the cable through the electric winch traction adjustment.

[0047] S2, fastening the stern and the figure-of-eight cable of the shore base, one end of the figure-of-sight cable is connected with the electric cable winch installed in the afterbody of the hull 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com