File envelope filling printer

A technology for printers and archives, applied in printing devices, printing, transfer materials, etc., can solve problems such as inability to meet office needs, low efficiency, and ordinary printers are not suitable for filling in file covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

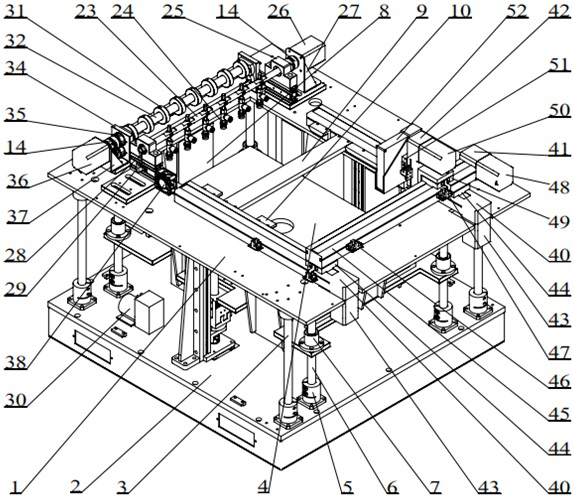

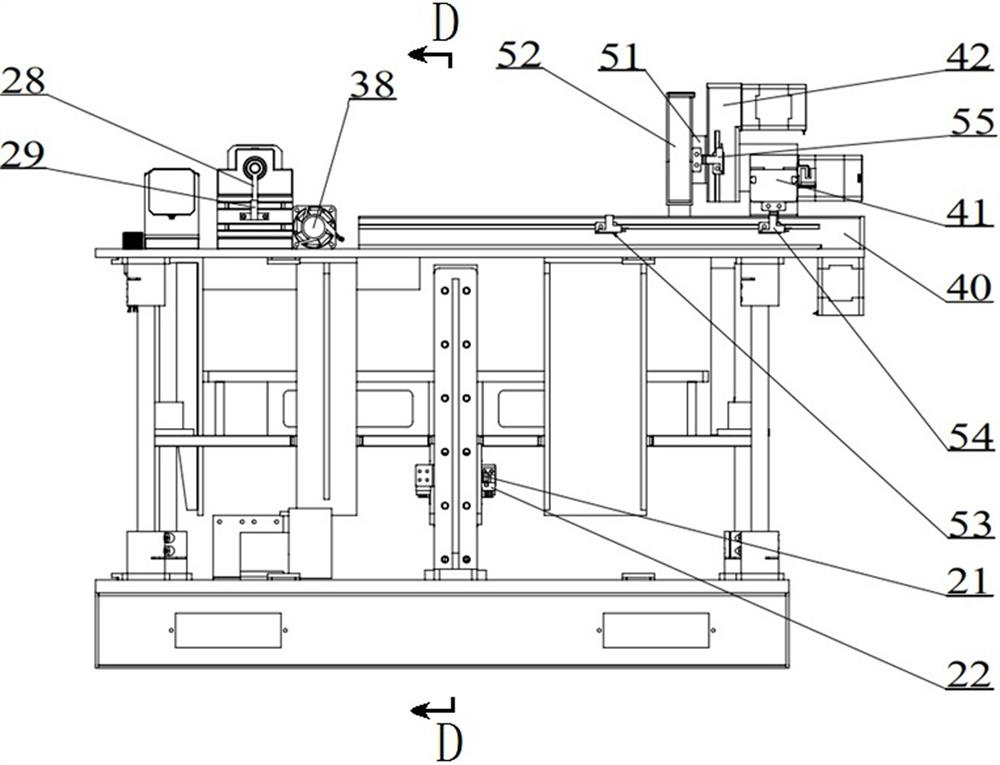

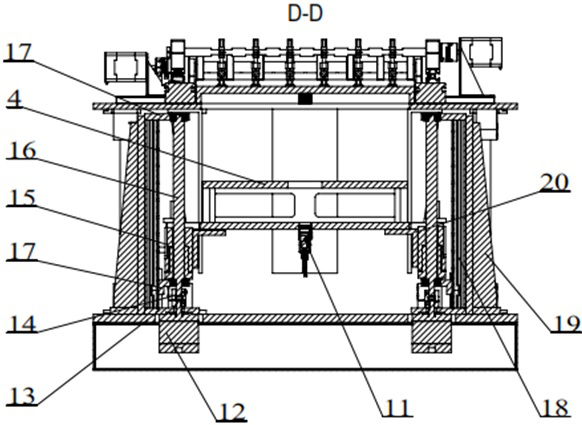

[0035] Refer to attached Figure 1-5 A file cover filling printer is composed of a fuselage body, a paper storage bin, a paper feeding and feeding mechanism, a writing and printing mechanism, and a paper taking and removing mechanism.

[0036] The fuselage body is the fixed installation basis of all functional mechanisms. The fuselage body includes structural parts such as the lower base plate 2, the support column 3, and the upper bearing plate 1, forming a box-shaped frame, and each functional mechanism component is installed and fixed on the fuselage body. corresponding position.

[0037] The paper storage bin is arranged in the middle of the fuselage body and is used for storing archive cover papers.

[0038] The paper feeding and feeding mechanism is arranged in the middle of the fuselage body, and is the feeding and conveying part of the archive cover paper.

[0039] The writing and printing mechanism is arranged on the upper part of the fuselage body, and is a printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com