Automatic loading and unloading equipment for compartment products

A product and cabin technology, applied in the field of automatic loading and unloading equipment for cabin products, can solve problems such as unusable, high labor intensity, and low efficiency, and achieve the effects of improving work efficiency, reducing labor intensity, and ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

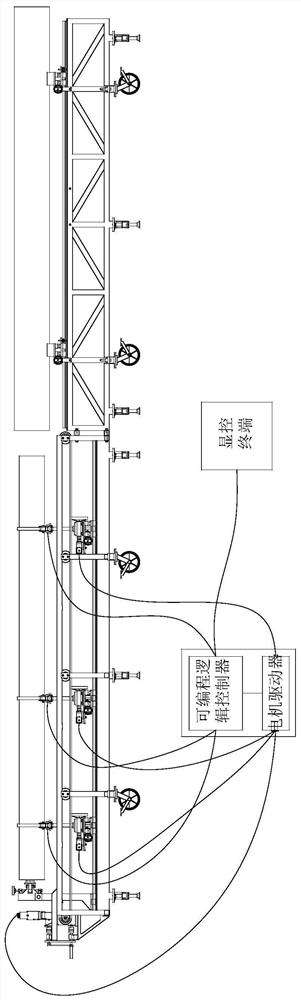

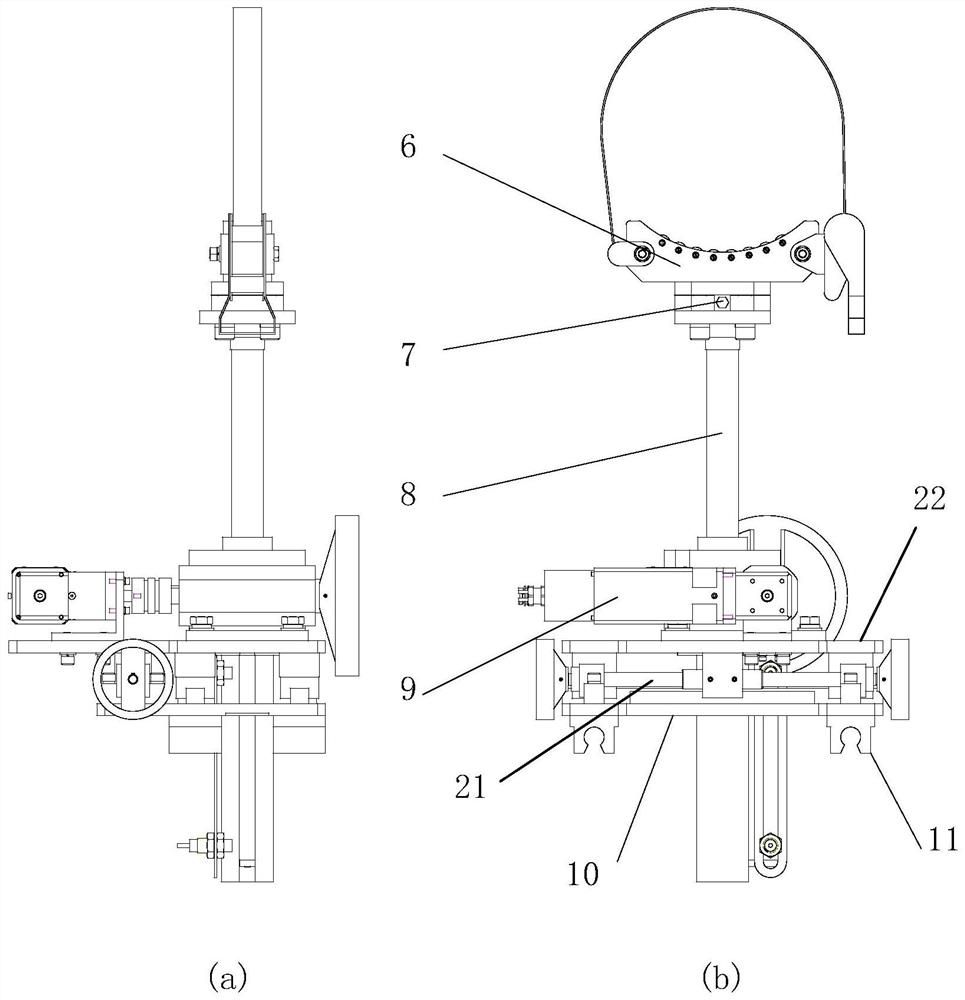

[0021] The following will combine Figure 1 ~ Figure 4 A further detailed description will be given to the automatic loading and unloading equipment for cabin products of the present invention.

[0022] figure 1 The above is a schematic diagram of the automatic loading and unloading equipment for cabin products in a preferred embodiment of the present invention.

[0023] see figure 1 , the automatic loading and unloading equipment for cabin products of the present invention includes a cabin product platform, a cylinder platform and a control system; when in use, the cabin product platform is mechanically connected to the cylinder platform, and the control system is connected to the cylinder platform. The cabin product platform is electrically connected; the cabin product is installed on the cabin product platform, and the launching tube is installed on the tube platform.

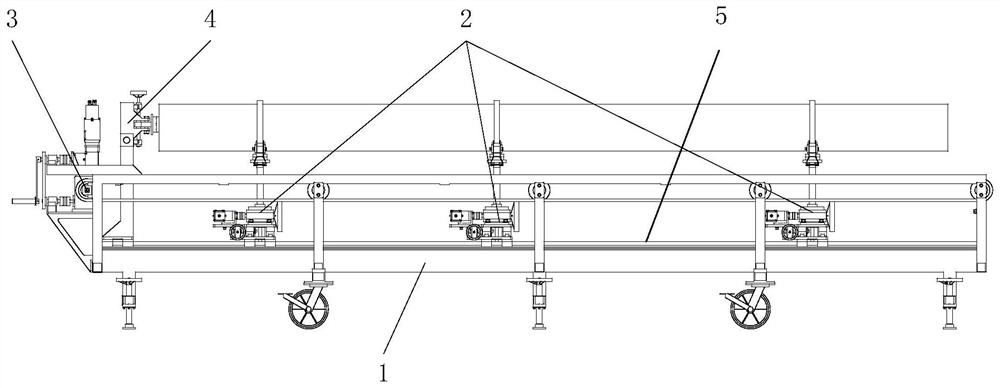

[0024] figure 2 The above is a schematic diagram of the cabin product platform in the preferred embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com