Expansion filling method based on gangue filling

A technology of gangue and backfill, which is applied in the fields of backfill, earthwork drilling, safety devices, etc., can solve the problems of low backfilling compaction strength and small range, solve the problem of backfilling, improve the filling rate, and improve resource recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention proposes an expansion filling method based on gangue filling. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

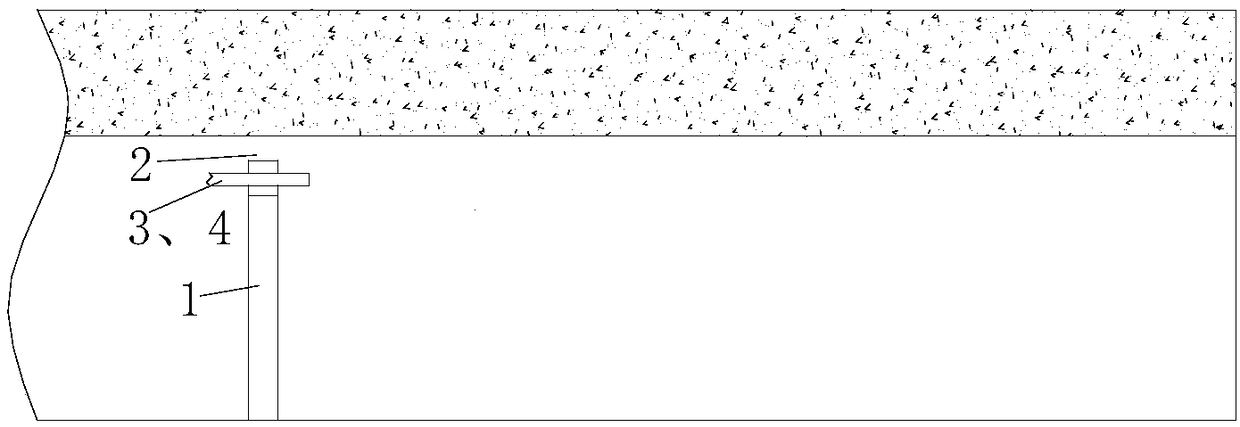

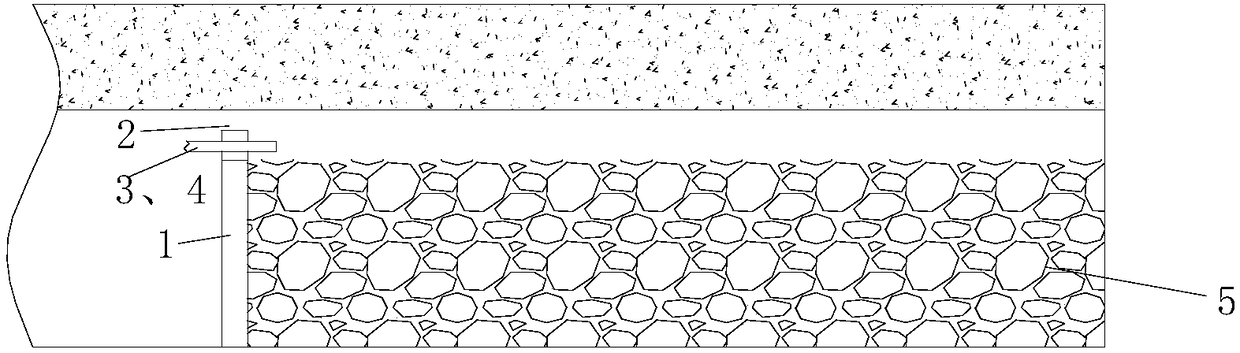

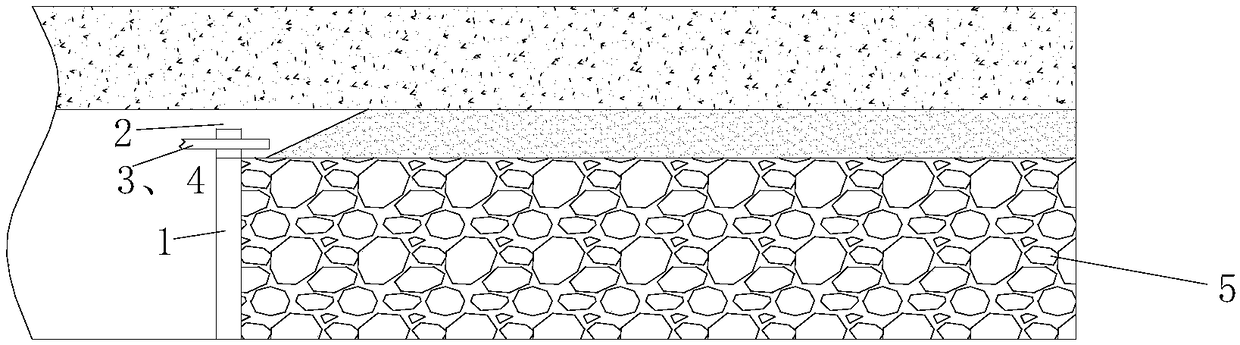

[0027] combine Figure 1 to Figure 5 Shown, the present invention a kind of expansion filling method based on gangue filling, specifically comprises the following steps:

[0028] In the first step, after the coal cutting is completed, a partition wall 1 is set in the goaf along the direction of the working face. The passage opening 2 for filling gangue and expansion materials, the diameter of the passage opening 2 is equal to 1 / 5 of the height of the goaf, and the separation wall 1 separates the goaf into a closed filling space. The partition wall 1 is spliced by a plurality of templates, and the outside of the templates are fixed by brackets.

[0029] The second step is to fill the gangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com