Heterogeneous catalytic ozonization pharmaceutical wastewater treatment device and process

A technology of ozone catalytic oxidation and pharmaceutical wastewater, applied in the direction of oxidized water/sewage treatment, non-polluted water treatment, natural water treatment, etc., can solve the problems of poor ozone mass transfer efficiency, increased water treatment cost, and limit the use of ozone. Improve the service life, improve the utilization rate of ozone, and solve the effect of secondary pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

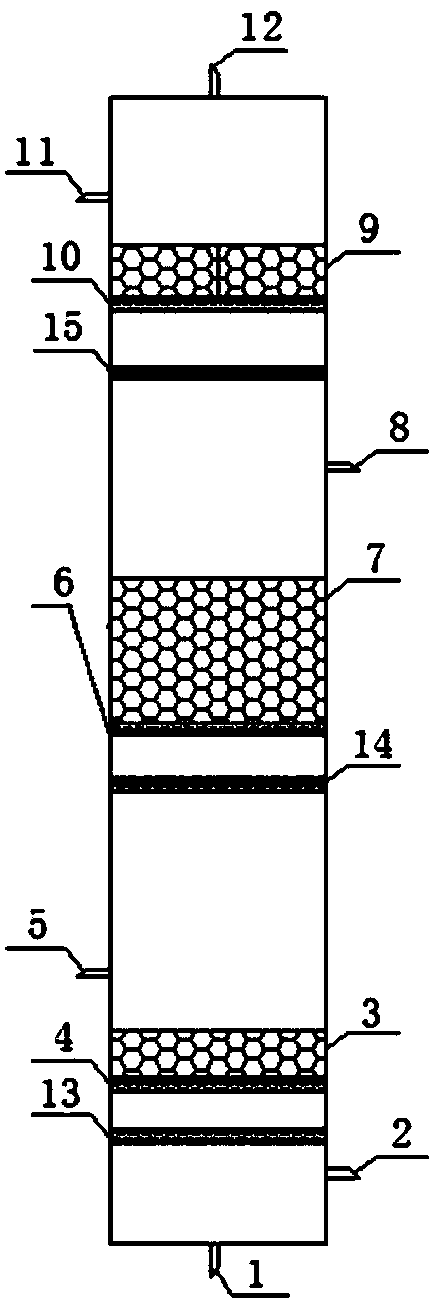

[0050] a. Immerse 20g of ceramsite carrier with a diameter of 3-5mm in a mixed solution of 1mol / L nickel nitrate and ferric nitrate for 24h, dry at 110°C, and bake at 600°C for 5h to make a finished catalyst;

[0051] b. Spread the waste water and the catalyst in three layers on the first catalyst support plate 4, the second catalyst support plate 6, and the third catalyst support plate 10 of the ozone catalytic oxidation reactor in a ratio of 1:100 (liter / gram), forming Catalyst bed, the volume ratio of the three-layer catalyst bed is 1:2:1, and then the three sections of the ozone catalytic oxidation reactor are connected tightly with flanges.

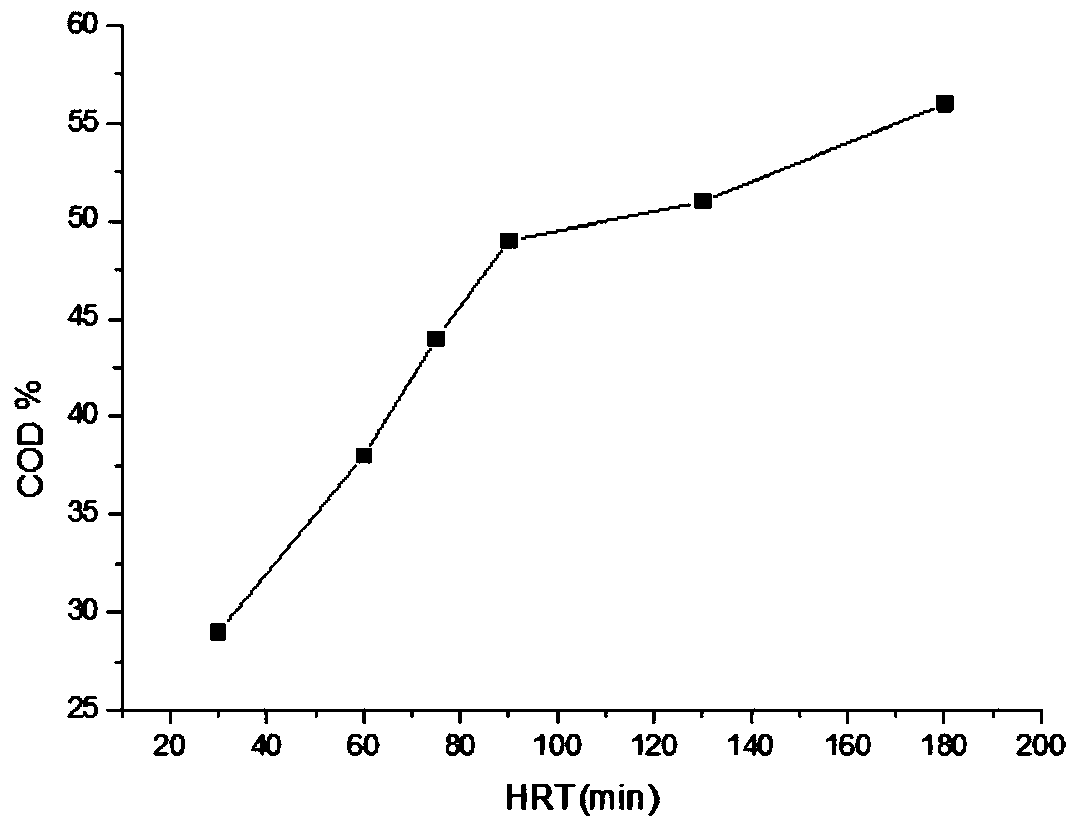

[0052] The treated pharmaceutical wastewater is 7.2L, and the COD in the wastewater is 1000mg / L.

[0053] c. Use a pump to add pharmaceutical production wastewater into the ozone catalytic oxidation reactor, and the ozone gas flows into the ozone catalytic oxidation reactor through the inlet 1 and the wastewater, and then enters the ...

Embodiment 2

[0058] a. Immerse 20 g of a ceramsite carrier with a diameter of 4 mm in a mixed solution of 1 mol / L nickel nitrate and ferric nitrate for 24 h, dry at 105 ° C, and bake at 600 ° C for 5 h to make a finished catalyst;

[0059] b. Spread the waste water and the catalyst in three layers on the first catalyst support plate 4, the second catalyst support plate 6, and the third catalyst support plate 10 of the ozone catalytic oxidation reactor in a ratio of 1:100 (liter / gram), forming Catalyst bed, the volume ratio of the three-layer catalyst bed is 1:2:1, and then the three sections of the ozone catalytic oxidation reactor are connected tightly with flanges.

[0060] The treated pharmaceutical wastewater is 7.2L, and the COD in the wastewater is 1000mg / L.

[0061] c. Use a pump to add pharmaceutical production wastewater into the ozone catalytic oxidation reactor, and the ozone gas flows into the ozone catalytic oxidation reactor through the inlet 1 and the wastewater, and then en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com