Concrete mixer

A technology for mixers and concrete, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as waste and inflexible movement of mixers, and achieve the effect of saving labor costs and moving flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention provides a concrete mixer which can move flexibly in a small area and can save manpower.

[0014] In order to achieve the above object, the present invention adopts the following technical solutions

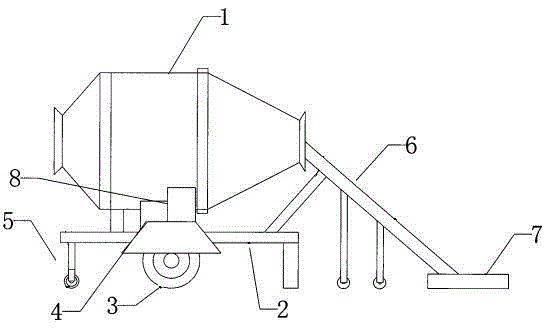

[0015] A concrete mixer, which includes a mixing bucket 1, a frame 2, wheels 3, a reduction box 4, an electric control box 8, a direction changing device 5, a transmission device 6, and a shovel box 7. Described mixing tank 1 is arranged on frame 2, and described wheel 3 is installed on the bottom of frame 2 both sides, and described reduction box 4 and electric control box 5 are installed on the top of frame 2 side, and reduction box 4 and The electric control box 8 is electrically connected together, and also includes a reversing device 5 and a conveying device 6, and the conveying device 6 includes a conveyor belt and a support frame, and the top of the conveyor belt is arranged at the feed inlet of the mixing drum 1, so that The supporting frame is suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com