Separating and recycling method and device for solvent-water mixture containing impurities prone to scale formation

A separation recovery and mixture technology, applied in the purification/separation of oxygenated compounds, separation method, separation/purification of carbonyl compounds, etc., can solve the problems of easy blockage of reboiler, high energy consumption, low yield, etc., and achieve The effect of reducing steam consumption, saving steam consumption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

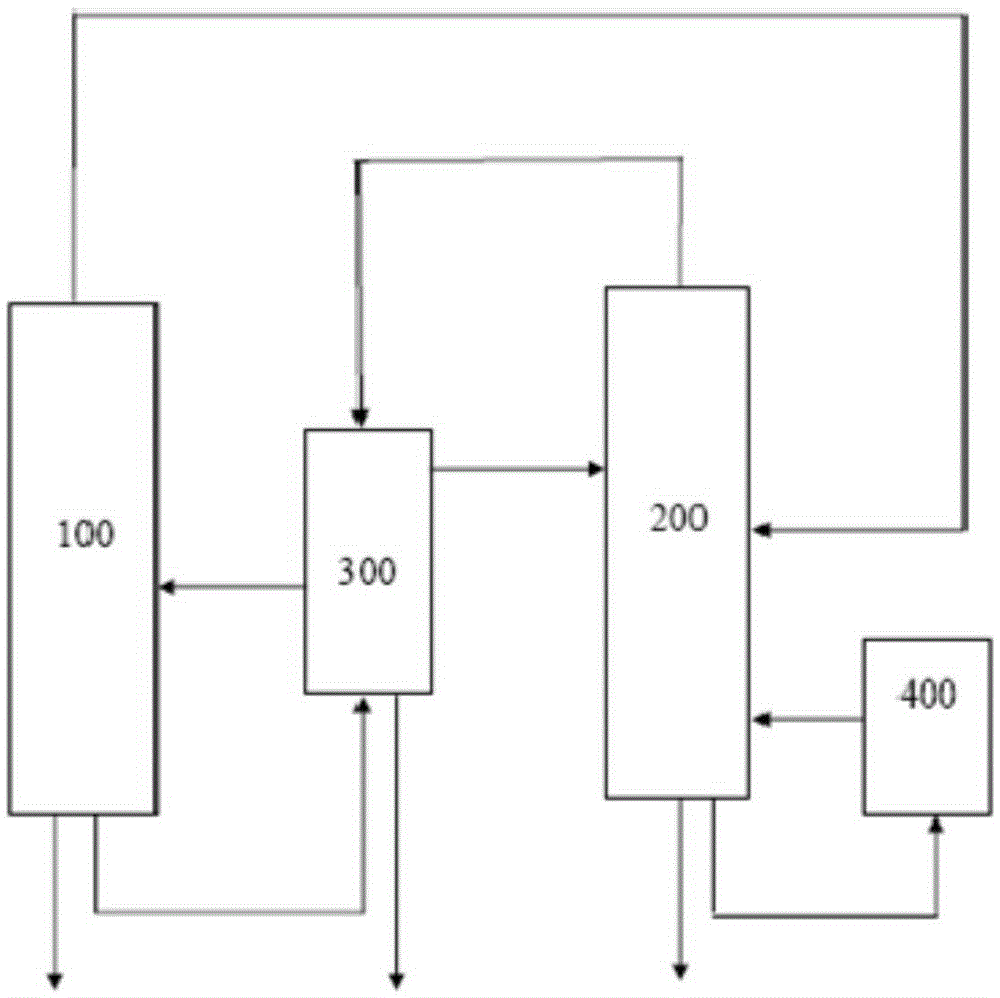

[0050] figure 1 A structural schematic diagram of a specific embodiment 1 of a separation and recovery device for a solvent-water mixture containing impurities prone to fouling is provided. The device includes a vacuum stripping unit 100 and a rectification unit 200 connected in sequence, and the rectification unit 200 is connected with The heat supply unit 400 that provides heat for the device, the heat exchange unit 300 is set between the vacuum stripping unit 100 and the rectification unit 200, the heat exchange unit 300 is used to collect the latent heat of condensation of the product of the rectification unit 200 as a vacuum lift The heat source of distillation unit 100. The waste water can be recovered from the vacuum stripping unit 100 and the rectification unit 200 , and the required solvent product can be obtained from the heat exchange unit 300 .

specific Embodiment approach 2

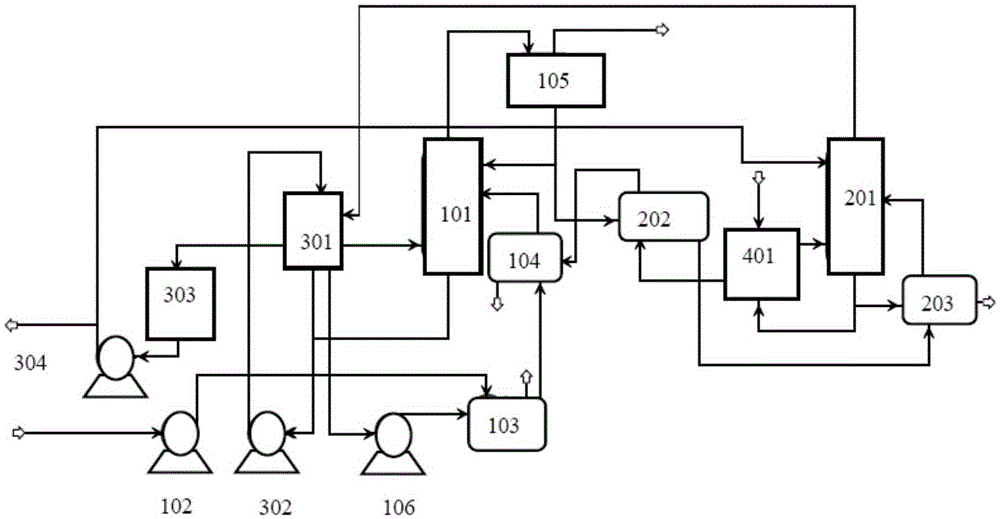

[0052] figure 2A schematic structural diagram of the second embodiment of a separation and recovery device for a solvent-water mixture containing impurities prone to fouling is provided, as described in the first embodiment, wherein the vacuum stripping unit includes: a vacuum stripping tower 101 , feed pump 102, condensation preheater 103, hot water preheater 104, tower top condenser 105, waste water pump 106; Described rectification unit comprises: rectification tower 201, condensation water preheater 202, rectification A kettle liquid preheater 203; the heat exchange unit includes: a falling film evaporator 301, a circulation pump 302, a liquid phase reflux tank 303, and a discharge pump 304; the heat supply unit is a reboiler 401.

[0053] The feed liquid is sent into the condensation preheater 103 and the hot water preheater 104 by the feed pump 102, and is sent to the feed port of the vacuum stripping tower 101 after two-stage preheating; Out into the tower top condens...

Embodiment 1

[0059] Utilize the separation and recovery device of the solvent-water mixture containing the easy-to-scale impurities provided by the second embodiment to separate the isopropanol-water mixture containing the easy-to-scale impurities, including the following steps:

[0060] 1. The feed liquid with a mass content of isopropanol of 5% is sent to the vacuum stripping tower, and the temperature is 55°C after secondary preheating; the operating pressure of the vacuum stripping tower is 15kPa, and the temperature of the top material is 50 °C, the reflux ratio is 2, and the reflux temperature is 40 °C;

[0061] 2. The top of the vacuum stripping tower is extracted and sent to the rectification tower, and the temperature is 90°C after two-stage preheating; the operating pressure of the rectification tower is 120kPa, the temperature of the top material is 85°C, and the reflux ratio is 2 , The reflux temperature is 60°C;

[0062] 3. Obtaining mass fraction after rectification is 80% i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com