Detachable chlor-alkali special valve having leakage preventing device

An anti-leakage, special valve technology, applied in the field of shut-off valve and regulating valve, can solve the problems of inability to disassemble, clean, inconvenient replacement of parts, deformation of valve stem, etc., to achieve the effect of easy disassembly, easy cleaning, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

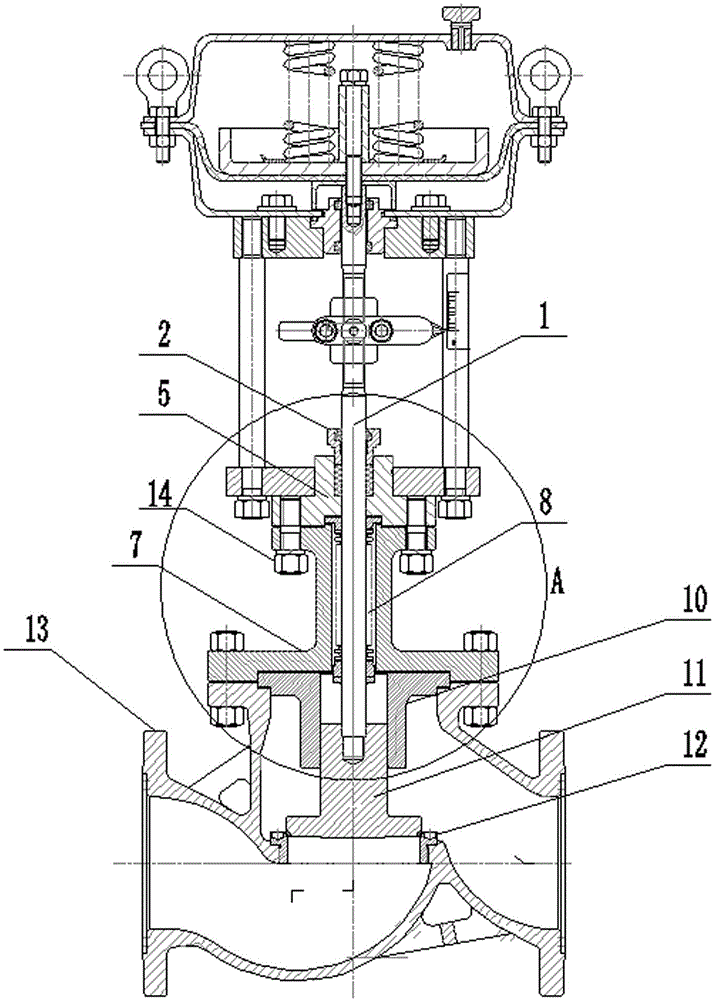

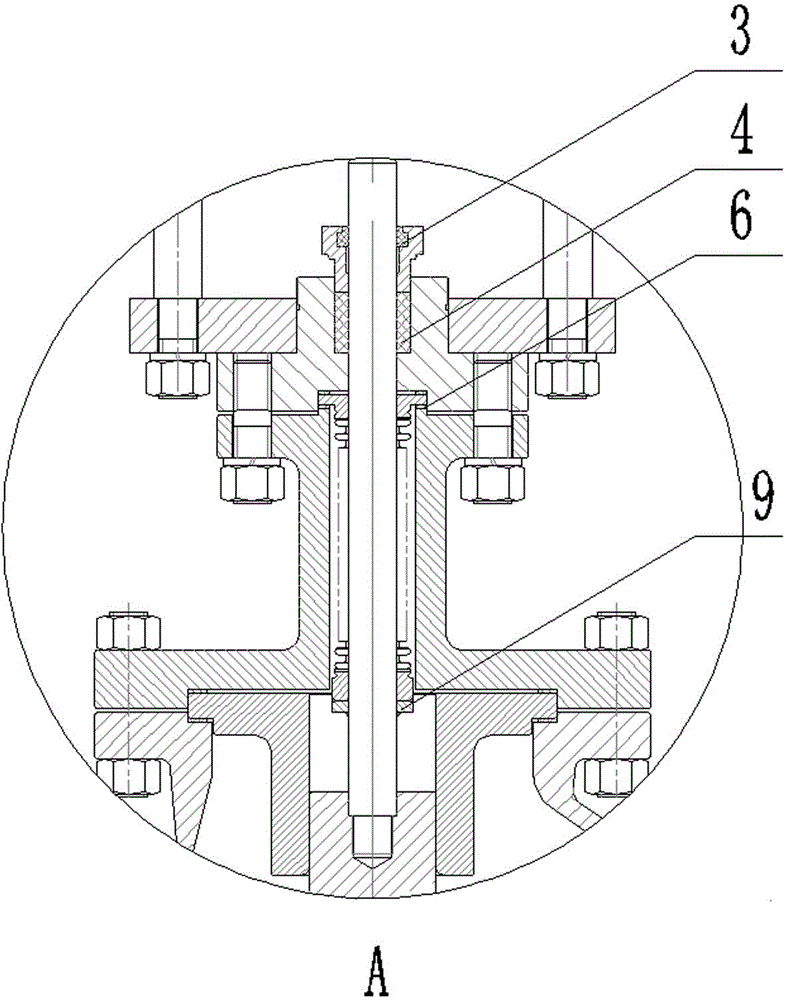

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] The present invention is a detachable chlor-alkali special valve with an anti-leakage device, which includes a special valve body, an anti-leakage device, and a control device. The special valve body includes a valve disc 11, a valve seat 12, and a valve body 13. The valve Body 13 is fixedly connected with the anti-leakage device, and the control device includes a valve stem 1, and the valve stem 1 is fixedly connected with the valve disc 11; a guide block 10 is also provided in the special valve body, and the valve The petal 11 slides along the inner cavity of the guide block 10, the anti-leakage device includes a packing gland 2, an upper valve cover 5, a lower valve cover 7, and a bellows 8, and the inner wall of the gland 2 is provided with a dust-proof ring groove , the dust-proof ring groove is provided with a dust-proof ring 3, and the valve ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com