Closed type capping method by upward filling mining

A backfill mining and closed technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of unsatisfactory filling effect and easy weathering of the upper part, and achieve the effect of solving the problem of filling and topping, low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

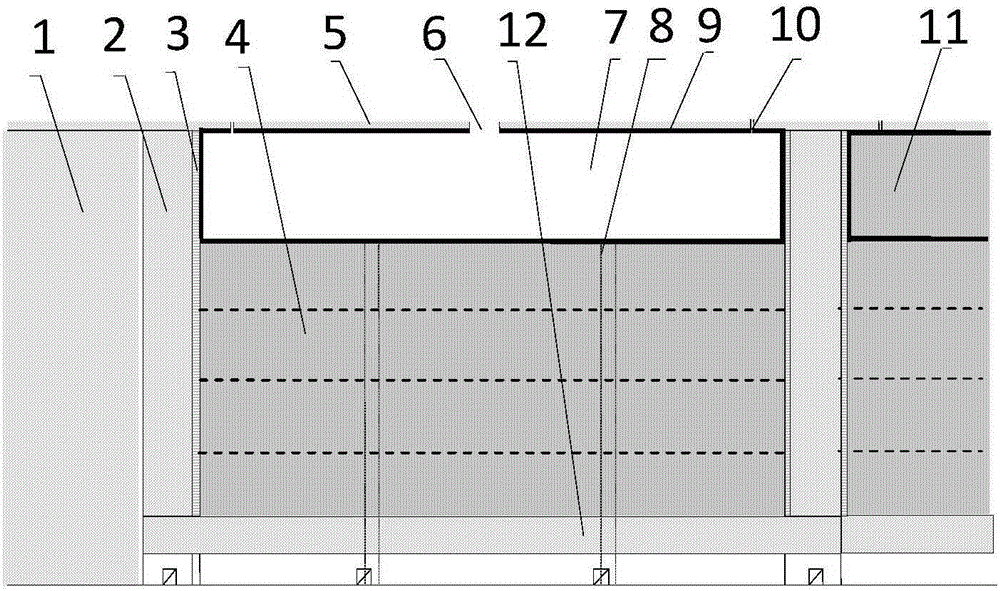

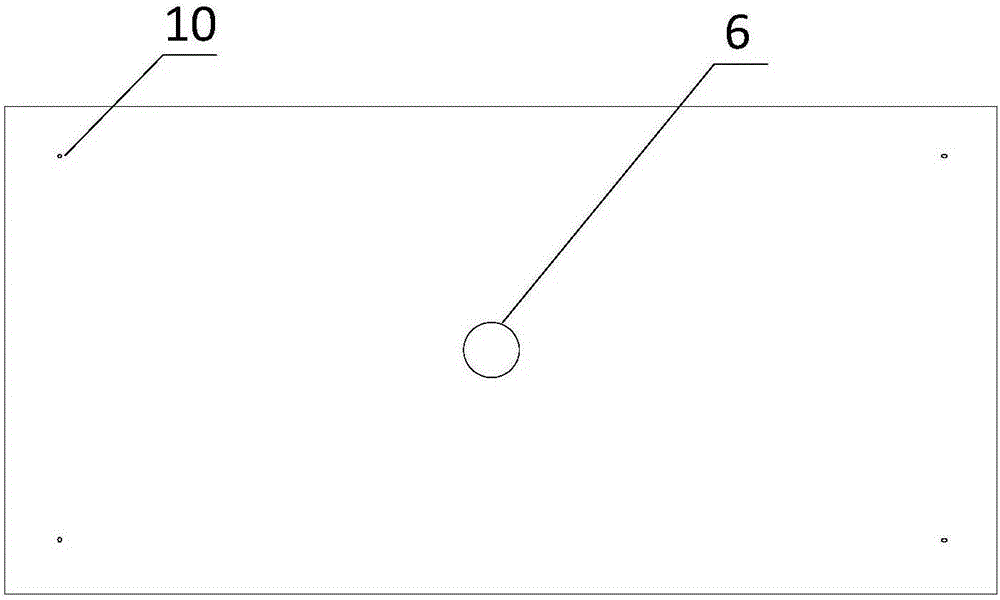

[0016] Further describe the present invention below in conjunction with accompanying drawing.

[0017] Such as figure 1 and figure 2 As shown, a closed top-capping method for upward filling mining, this method divides the ore block horizontally into layers on the vertical height, and recovers layer by layer from bottom to top. Build ore-drawing chute and pedestrian's patio 8 along the way in layer filling body 4, ore-drawing chute and pedestrian's patio 8 can be used as and discharge well. Filling wells 6 are arranged in the ore block for lowering the filling materials, and sometimes they are also used as lifting equipment, materials, ventilation and pedestrians. The mining process includes rock drilling, ore collapse, ore extraction, as well as construction of ore-drawing chutes and pedestrian patios 8, construction of partition walls 3, filling and bedding and cementing the floor. It is characterized in that after mining the last layer, use a drilling rig to drill four e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com