Dry-mixed mortar water retention thickener and preparation method thereof

A water-retaining thickener and a technology for dry-mixed mortar, which are applied in the field of water-retaining thickener for mortar, water-retaining thickener for dry-mixing mortar, and the field of preparation of the water-retaining thickener for dry-mixed mortar, which can solve the problem of not giving a guiding scheme, etc. problems, to achieve the effect of improving construction efficiency, good workability, and increased length of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

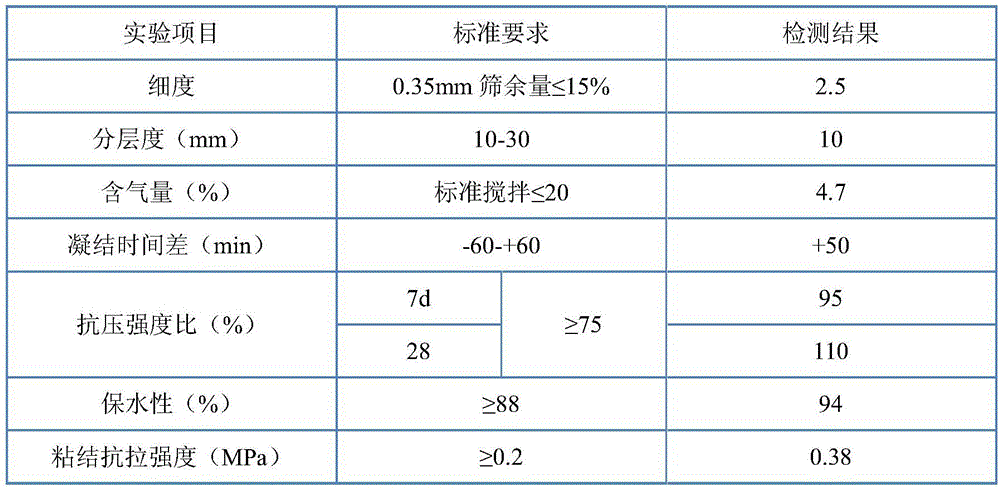

[0019]Embodiment 1: The water-retaining thickener for dry-mixed mortar of the present invention is formed by mixing the raw materials of the following components and weight percentages: 50% magnesium aluminum silicate, 6% sulfonate, 35% methyl cellulose , AES air-entraining agent 3%, AOS air-entraining agent 3%, polycarboxylate multi-polymer superplasticizer 1.5%, powder aliphatic water reducer 1.5%. Wherein, the fineness of the magnesium aluminum silicate is 300 mesh; the sulfonate is powder; the cellulose is methyl cellulose, viscosity (20°C, 2% aqueous solution): 100,000-200,000 mPa ·s; the air-entraining agent is a compound of AES air-entraining agent and AOS. The water reducer is a polycarboxylate multi-polymer high-efficiency water reducer (commercially available) and a powder aliphatic water reducer used in combination. Compared with traditional lime-based and single-mixed air-entraining additives, the present invention has improved bonding strength, good water resista...

Embodiment 2

[0021] Embodiment 2: The water-retaining thickener for dry-mixed mortar of the present invention is formed by mixing the raw materials of the following components and weight percentages: 55% magnesium aluminum silicate, 4% sulfonate, 35% hydroxyethyl cellulose %, AES air-entraining agent 2%, AOS air-entraining agent 2%, polycarboxylate multi-polymer high-efficiency water reducer 1.0%, powder aliphatic water reducer 1.0%. Wherein, the fineness of the magnesium aluminum silicate is 300 mesh; the sulfonate is powder; the cellulose is hydroxyethyl cellulose, viscosity (20°C, 2% aqueous solution): 100,000-200,000 mPa·s; the air-entraining agent is a compound of AES air-entraining agent and AOS. The water reducer is a polycarboxylate multi-polymer high-efficiency water reducer combined with a powder aliphatic water reducer. Compared with traditional lime-based and single-mixed air-entraining additives, the present invention has improved bonding strength, good water resistance, free...

Embodiment 3

[0023] Embodiment 3: The water-retaining thickener for dry-mixed mortar of the present invention is formed by mixing the raw materials of the following components and weight percentages: 51% magnesium aluminum silicate, 5% sulfonate, hydroxypropyl methylcellulose 38% prime, 2% AES air-entraining agent, 2% AOS air-entraining agent, 1.0% polycarboxylate multi-polymer superplasticizer, 1.0% powder aliphatic water reducer. Wherein, the fineness of the magnesium aluminum silicate is 350 mesh; the sulfonate is powder; the cellulose is hydroxypropyl methylcellulose, viscosity (20°C, 2% aqueous solution): 100,000 to 200,000 mPa·s; the air-entraining agent is a compound of AES air-entraining agent and AOS. The water reducer is a polycarboxylate multi-polymer high-efficiency water reducer combined with a powder aliphatic water reducer. Compared with traditional lime-based and single-mixed air-entraining additives, the present invention has improved bonding strength, good water resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com