Dry-mixed mortar and preparation method thereof

A technology of dry-mixed mortar and parts by weight, applied in the field of materials, can solve the problems of high material consumption, high maintenance costs in the later period, and low construction efficiency, and achieve the effects of improving the quality of the slurry layer, saving the amount of mortar, and improving the construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

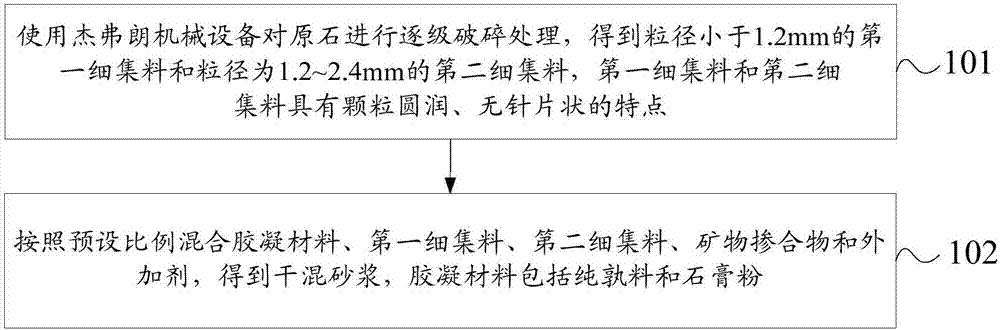

[0041] refer to figure 1 , which shows a flow chart of a method for preparing dry-mixed mortar according to an embodiment of the present invention, the method specifically includes:

[0042] Step 101, use Geoffron mechanical equipment to crush the rough stone step by step to obtain the first fine aggregate with a particle size of less than 1.2mm and the second fine aggregate with a particle size of 1.2-2.4mm, the first fine aggregate and The second fine aggregate has the characteristics of round particles and needle-free flakes.

[0043] Step 102, mixing the cementitious material, the first fine aggregate, the second fine aggregate, the mineral admixture and the admixture according to a preset ratio to obtain a dry-mixed mortar. The cementitious material includes pure clinker and gypsum powder.

[0044] When preparing dry-mixed mortar, the amount of cementitious material is 10-20 parts by weight, the amount of the first fine aggregate is 40-50 parts by weight, the amount of t...

Embodiment 1

[0054] The raw stone is crushed step by step by using Geoffron mechanical equipment to obtain the first fine aggregate with a particle size of less than 1.2 mm and the second fine aggregate with a particle size of 1.2 to 2.4 mm. The first fine aggregate and the obtained The second fine aggregate has the characteristics of round particles and needle-free flakes;

[0055] Mix 10 parts by weight of the cementitious material, 40 parts by weight of the first fine aggregate, 20 parts by weight of the second fine aggregate and 10 parts by weight of the mineral admixture to obtain a dry-mixed mortar; wherein, 10 parts by weight of the cementitious material includes 9.5 parts by weight of pure clinker and 0.5 parts by weight of gypsum powder; the mineral admixture is mineral powder.

Embodiment 2

[0057] The raw stone is crushed step by step by using Geoffron mechanical equipment to obtain the first fine aggregate with a particle size of less than 1.2 mm and the second fine aggregate with a particle size of 1.2 to 2.4 mm. The first fine aggregate and the obtained The second fine aggregate has the characteristics of round particles and needle-free flakes;

[0058] The cementitious material of 20 parts by weight, the first fine aggregate of 50 parts by weight, the second fine aggregate of 30 parts by weight, the mineral admixture of 20 parts by weight, the admixture of 0.05 parts by weight and The cyclodextrin of 0.4 parts by weight is mixed to obtain dry-mixed mortar;

[0059] Wherein, the cementitious material of 20 parts by weight includes the pure clinker of 19.2 parts by weight and the gypsum powder of 0.8 parts by weight; The stone powder, the admixture of 0.05 parts by weight includes latex powder of 0.02 parts by weight, stabilizer of 0.02 parts by weight and def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com