Al2O3-SiO2 content-graded refractory brick for stamp-charging coke oven

An al2o3-sio2, tamping coke oven technology, applied in the field of refractory materials, can solve the problems of furnace head fracture, large temperature change, high cost, etc., to ensure firmness and service life, high load softening temperature, and thermal shock resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Two, the preparation method of this specific embodiment

[0032] The preparation method of this specific embodiment is: first press the Al corresponding to each level 2 o 3 -SiO 2The high-quality raw materials are used for batching and mixed separately; then, 5~10wt% pulp waste liquid of each grade of raw materials is added to each grade of raw materials, mixed in a wet mill, and the mixed raw materials of all grades are poured into the respective mold In the corresponding space, shape and dry; then send the dried bricks into the tunnel kiln, and burn them at 1400~1500°C for 40 hours to make them. in:

[0033] The shape of the mold is the same as that of the Al 2 o 3 -SiO 2 The shape of the refractory bricks graded by quality and content, the mold is divided into n spaces by thin steel plates;

[0034] Forming is to pour the raw materials of all levels into the corresponding spaces in the mold, then take out the thin steel plate, and form it by isostatic pressing...

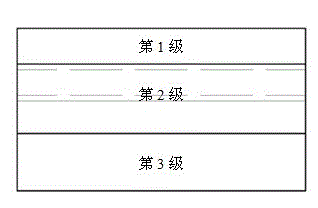

Embodiment 1

[0037] A kind of Al for tamping coke oven 2 o 3 -SiO 2 Quality content graded refractory bricks. The graded refractory bricks are made of 3 grade Al 2 o 3 -SiO 2 Made of high-quality raw materials; each grade of Al 2 o 3 -SiO 2 Al in raw materials 2 o 3 and SiO 2 The content changes step by step, that is, 3-level Al 2 o 3 -SiO 2 Among the quality raw materials:

[0038] Level 1: Al 2 o 3 Content>75wt%, SiO 2 Content<25wt%;

[0039] Level 2: Al 2 o 3 The content is 7 wt%~75wt%, SiO 2 Content 25 wt%~93wt%;

[0040] Level 3: Al 2 o 3 The content of 2 The content of >93wt%.

[0041] Except for the mould, the preparation method of this embodiment is the same as "2. The preparation method of this embodiment" in the unified description of this embodiment.

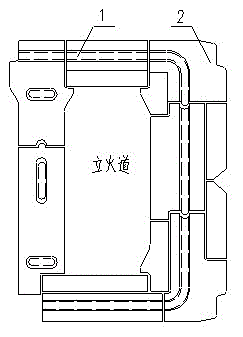

[0042] figure 1 Al for the stamping coke oven prepared in this embodiment 2 o 3 -SiO 2 Mass content graded refractory brick masonry in figure 1 At the position of 1﹟ refractory brick 1 shown, the shap...

Embodiment 2

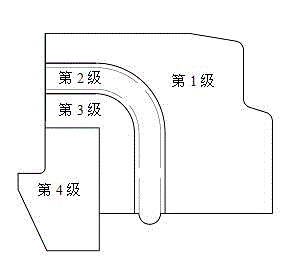

[0044] A kind of Al for tamping coke oven 2 o 3 -SiO 2 Quality content graded refractory bricks. The refractory brick is made of 4 grade Al 2 o 3 -SiO 2 Made of high-quality raw materials; each grade of Al 2 o 3 -SiO 2 Al in raw materials 2 o 3 and SiO 2 The content changes step by step, that is, 4 grades of Al 2 o 3 -SiO 2 Among the quality raw materials:

[0045] Level 1: Al 2 o 3 Content>75wt%, SiO 2 Content<25wt%;

[0046] Level 2: Al 2 o 3 The content is 41wt%~75wt%, SiO 2 The content is 25 wt%~59 wt%;

[0047] Level 3: Al 2 o 3 Content ≥ 7 wt% and 2 Content > 59wt% and ≤ 93wt%;

[0048] Level 4: Al 2 o 3 Content2 Content > 93wt%.

[0049] Except for the mould, the preparation method of this embodiment is the same as "2. The preparation method of this embodiment" in the unified description of this embodiment.

[0050] The tamping coke oven Al 2 o 3 -SiO 2 Mass content graded refractory brick masonry in figure 1 At the position of 2﹟ refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com