Method for preparing small hollow light aggregate concrete block from industrial solid waste residues

A lightweight aggregate concrete and solid waste slag technology, used in building components, buildings, building structures, etc., can solve the problems of poor thermal insulation performance, water and moisture resistance, poor forming performance of hollow blocks, and poor quality of hollow blocks. Unsatisfactory and other problems, to achieve the effect of increasing thermal insulation performance, increasing water and moisture resistance performance, and convenient masonry process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for preparing an insulating block, comprising the following steps:

[0056] (1) Construction waste granulation: Classify and place construction waste, and use jaw crusher and hammer crusher for crushing and screening respectively to obtain particles with a particle size of 1-8mm;

[0057] (2) Fine powder sedimentation: the particles obtained in step (1) are placed in a pool so that the water can completely submerge the particles, and the pool is stirred to ensure that the water and the particles can be suspended and rotated together to realize the washing of the particles. The particles are taken out and used as recycled aggregate; the pool is allowed to settle, and the upper layer of clear water is pumped out to obtain the washing soil;

[0058] (3) Preparation: mix recycled aggregate, coal-fired slag, and cement into a mixture according to volume percentage: 24% recycled aggregate, 62.3% coal-fired slag, and 13.7% cement;

[0059] (4) Moisture control in mol...

Embodiment 2

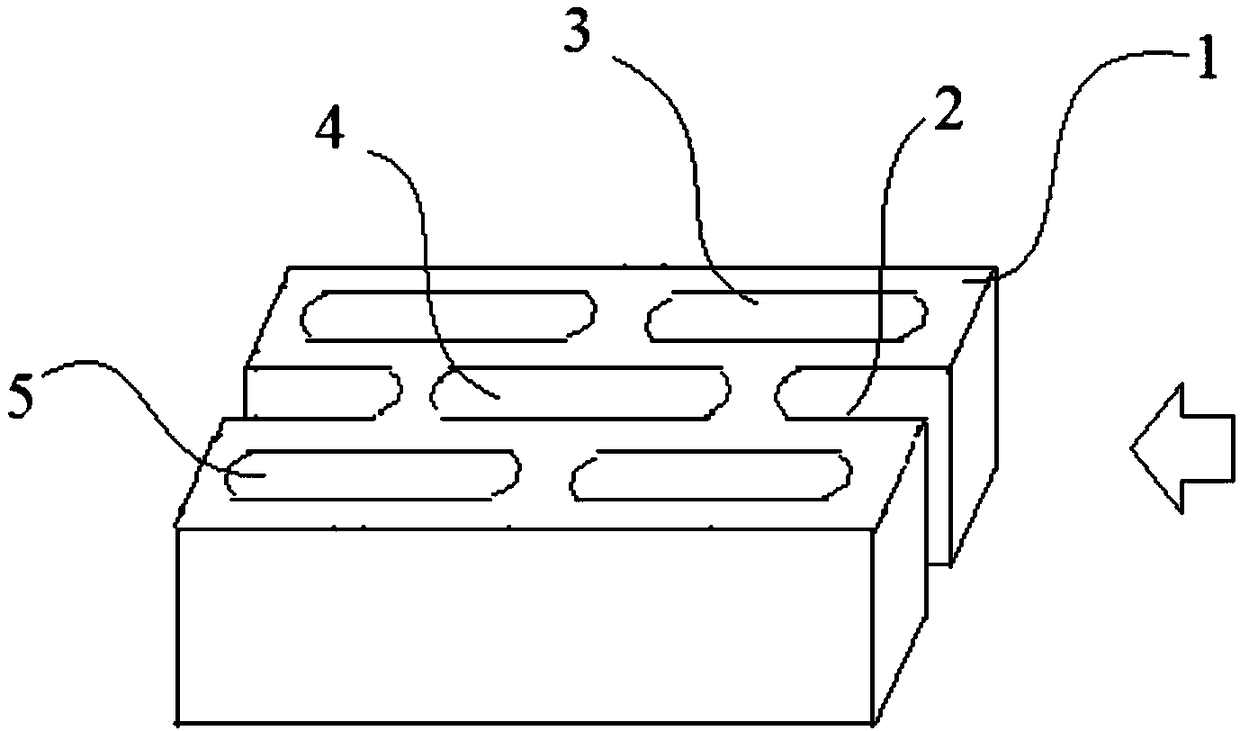

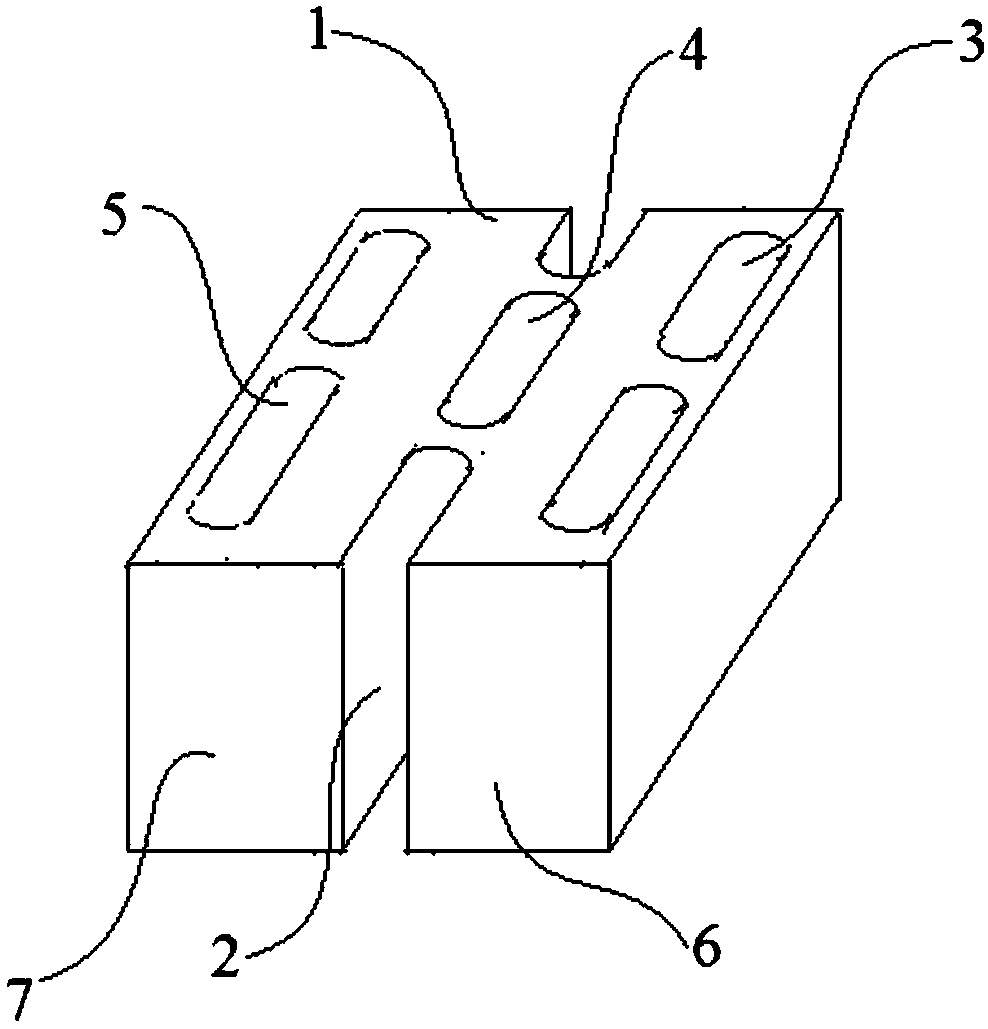

[0065] On the basis of Example 1, the construction waste was directly crushed into particles with a particle size of ≤9 mm as recycled aggregate, and prepared into thermal insulation blocks according to the preparation method of Example 1. The insulation block structure prepared by its mold is as follows: image 3 or Figure 4 shown.

Embodiment 3

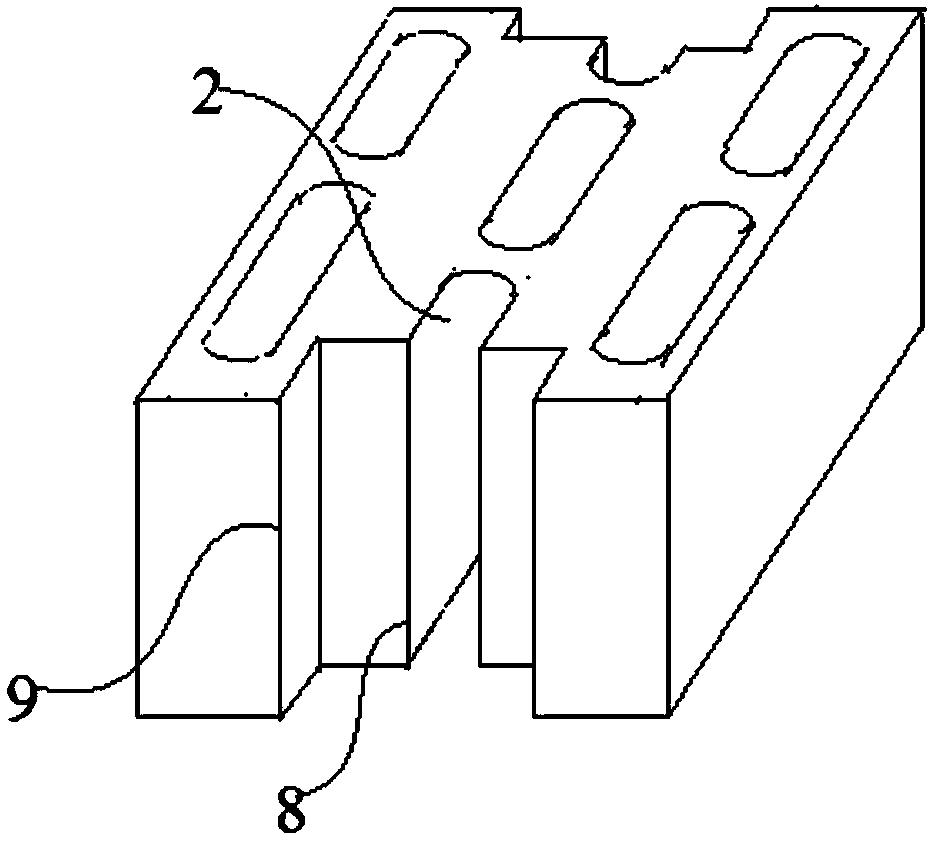

[0067] On the basis of Example 1, the vibration molding in step (4) is formed by extrusion, and conventional water vapor curing is used to prepare thermal insulation blocks. The insulation block structure prepared by its mold is as follows: Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com