High-alumina composite refractory brick

A high-alumina refractory brick technology, applied in the field of refractory materials, can solve the problems of shortened service life of refractory insulation lining, poor thermal insulation performance of refractory bricks, increased cost and construction period, etc., to reduce construction volume, excellent thermal insulation performance, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

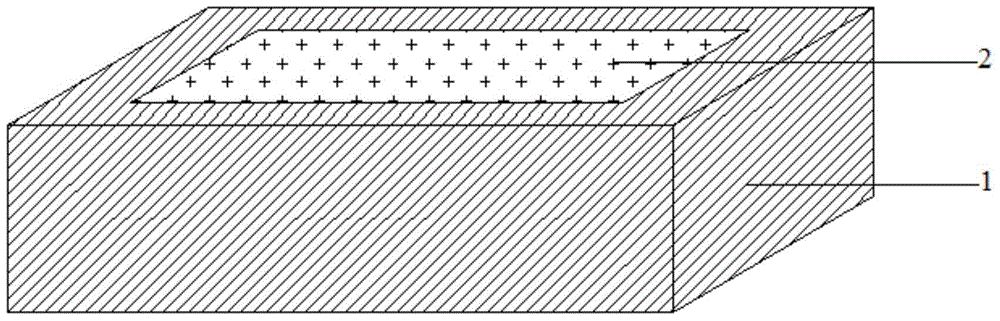

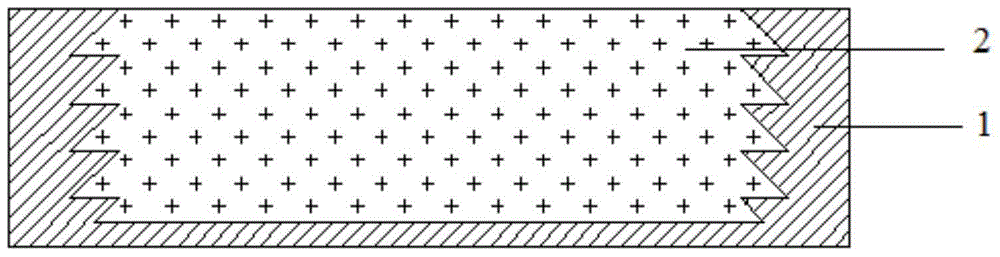

[0012] Such as figure 2 As shown, the present invention is a rectangular parallelepiped brick made of a high-alumina refractory material skeleton 1 filled with a rectangular concave surface structure and a high-alumina refractory material skeleton 1 with a zigzag corrugated structure on all four sides inside the concave surface, and a light-weight high-alumina refractory material filling layer 2 that closely fits the inside of the skeleton. body; and if figure 1 As shown, the high-alumina refractory skeleton of the brick body is flush with the upper surface of the lightweight high-alumina refractory filling layer.

[0013] The special high-alumina refractory skeleton 1 structure and the shape of the lightweight high-alumina refractory filling layer 2 ensure the stability and firmness of the combination of the two materials; the high-alumina refractory skeleton 1 plays the role of the working layer, so It has good fire resistance, high temperature structural strength, slag re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com