Vertical wedge-shaped refractory brick for rotary limestone kiln

A wedge-shaped refractory brick and wedge-shaped brick technology, applied in the field of refractory materials, can solve the problems of long maintenance time, poor refractory and thermal insulation performance, high production cost, etc., and achieve the effect of good airtight performance, good airtight performance, and flat joint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

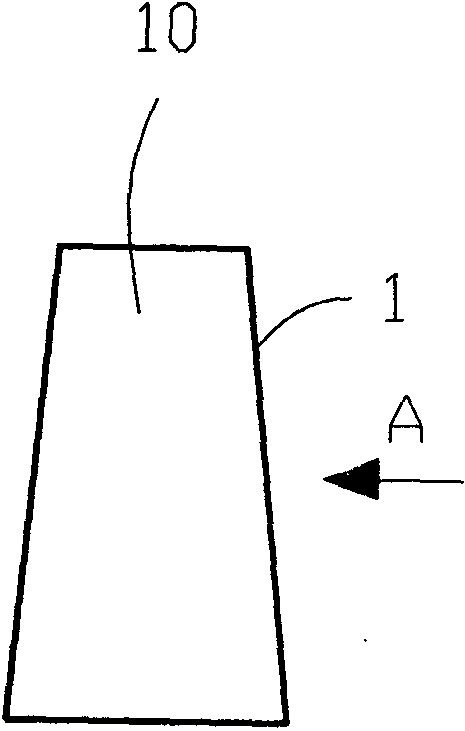

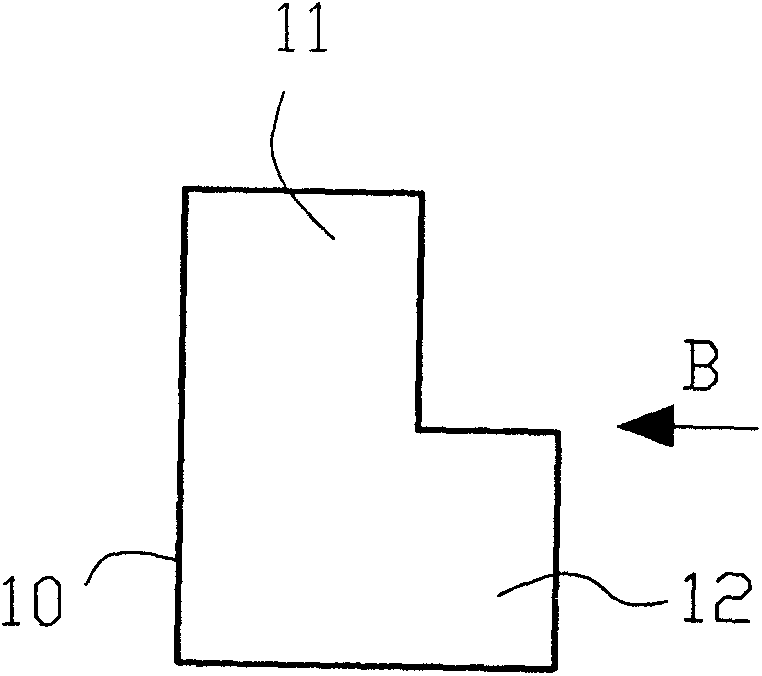

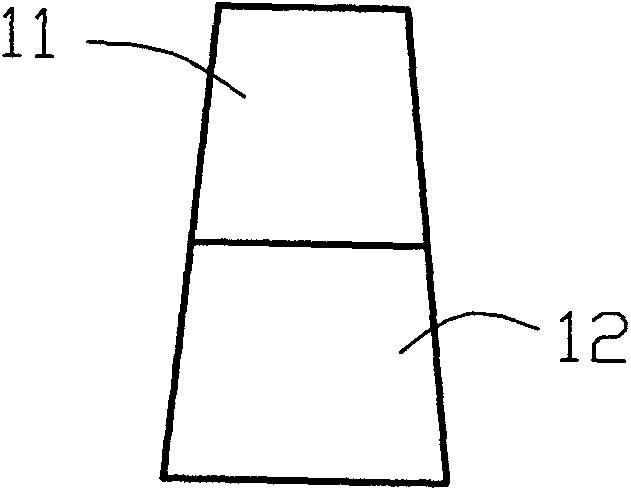

[0018] As shown in the figure, a limestone rotary kiln vertical wedge-shaped refractory brick according to the present invention is composed of a wedge-shaped port wedge-shaped brick 1, a kiln body wedge-shaped brick 2 and a tail-end wedge-shaped brick 3. It is characterized in that the port wedge-shaped brick 1 consists of The wedge tip 11 and the wedge bottom 12 are composed of one side of the port wedge brick 1 with a wedge-shaped end face 10, and one side of the wedge tip 11 and the wedge bottom 12 is provided with a step matching the kiln body wedge brick 2; the kiln body wedge brick 2 is composed of The wedge-shaped block 20 and the wedge-bottom block 21 are composed of an integrated structure. The bricks 3 match the steps; the wedge-shaped brick 3 at the tail end is composed of a wedge-shaped plug block 30 and a wedge-shaped bottom plug block 31, and one side of the wedge-shaped brick 3 at the tail end is a wedge-shaped tail surface 32, and the wedge-shaped plug block 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com