Flame-proof pouring material special for tertiary air tube shut-off device

A technology for refractory castables and gates, applied in the field of building materials, can solve problems such as affecting production efficiency, spalling of gate castables, poor wear resistance, etc. Good shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The special refractory castable for tertiary air duct shutter consists of the following components, expressed in weight percentage,

[0039] Mullite M70: 72%

[0040] Aluminum oxynitride: 8%

[0041] Pure calcium aluminate cement: 6%

[0042] a-AL 2 o 3 : 4%

[0043] Silica fume: 4%

[0044] Water: 6%.

[0045] In the preparation process, it is also necessary to additionally add dodecacalcium heptaaluminate, accounting for 2% of the total mass of the six components mixed, as a coagulant.

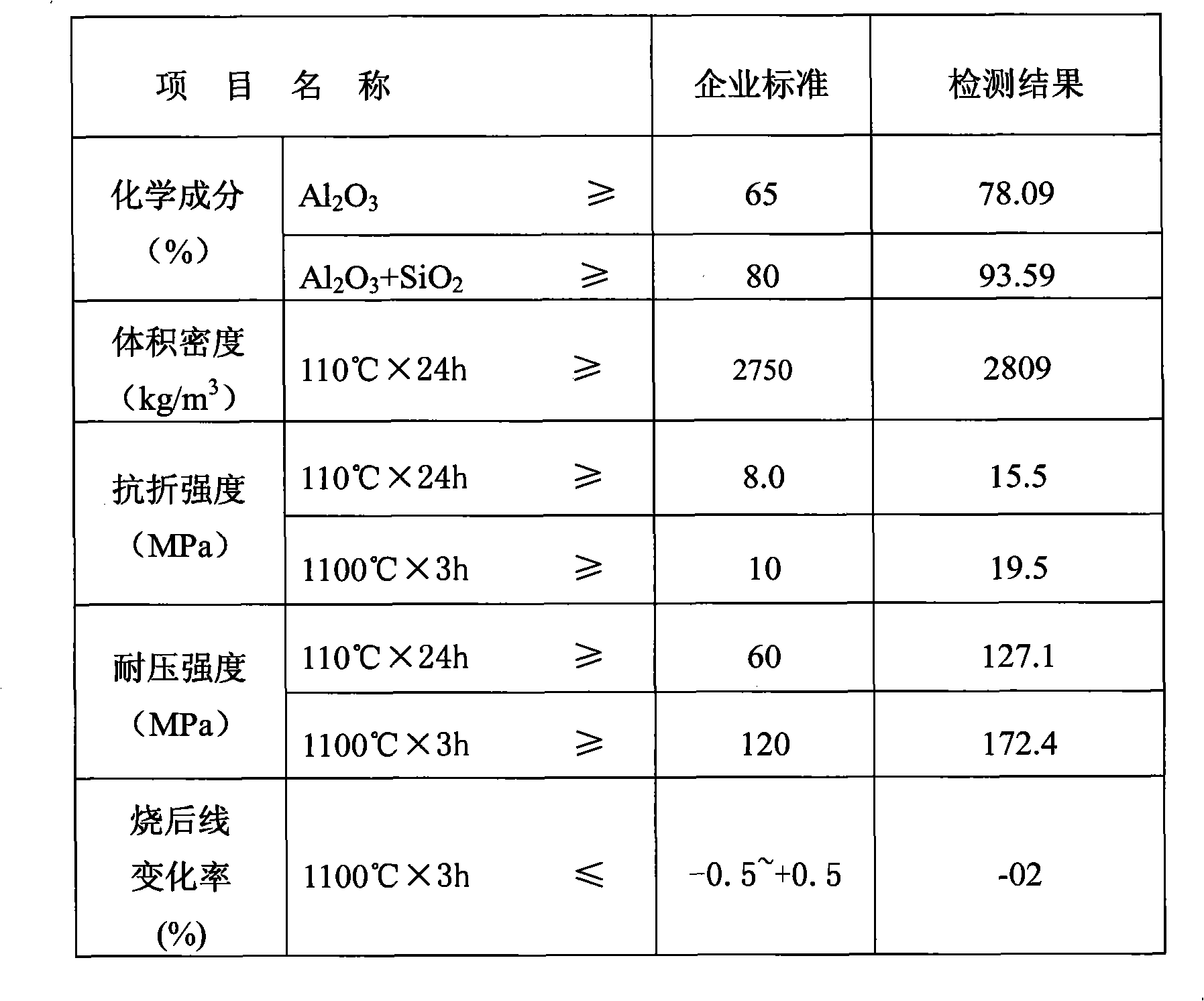

[0046] The special refractory castable for the tertiary air duct shutter of the present invention adopts high-quality raw materials with high purity, low impurities and high refractoriness, and strictly controls the composition of the matrix so that it forms a mullite crystal phase at high temperature. This kind of mullite The crystal phase is a columnar crystal with high strength and can form a mullite network skeleton structure, so it has extremely high wear resistance and th...

Embodiment 2

[0051] Consists of the following components, in percent by weight,

[0052] Mullite M70: 75%,

[0053] Aluminum oxynitride: 5%,

[0054] Pure calcium aluminate cement: 7%,

[0055] a-AL 2 o 3 : 3%,

[0056] Silica fume: 5%,

[0057] Water: 5%.

[0058] In the preparation process, it is necessary to additionally add dodecacalcium heptaaluminate, accounting for 2% of the total mass of the six components after mixing, as a coagulant.

[0059] Under such a ratio condition, the content of mullite M70 is the highest.

Embodiment 3

[0061] Mullite M70: 70%

[0062] Aluminum oxynitride: 10%

[0063] Pure calcium aluminate cement: 6%

[0064] a-AL 2 o 3 : 4%

[0065] Silica fume: 3%

[0066] Water: 7%.

[0067] In the preparation process, it is necessary to additionally add dodecacalcium heptaaluminate, accounting for 2% of the total mass of the six components after mixing, as a coagulant.

[0068] Under such a ratio condition, the content of mullite M70 is the lowest, and the cost is saved without reducing the use effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com