Corbel structure of coke dry quenching furnace

A technology of dry quenching coke oven and corbel, which is applied in the field of coking, can solve the problems of poor shear resistance of refractory bricks, increased gap 11, fracture of facing bricks, etc., and achieves the effects of small investment, improved production efficiency, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

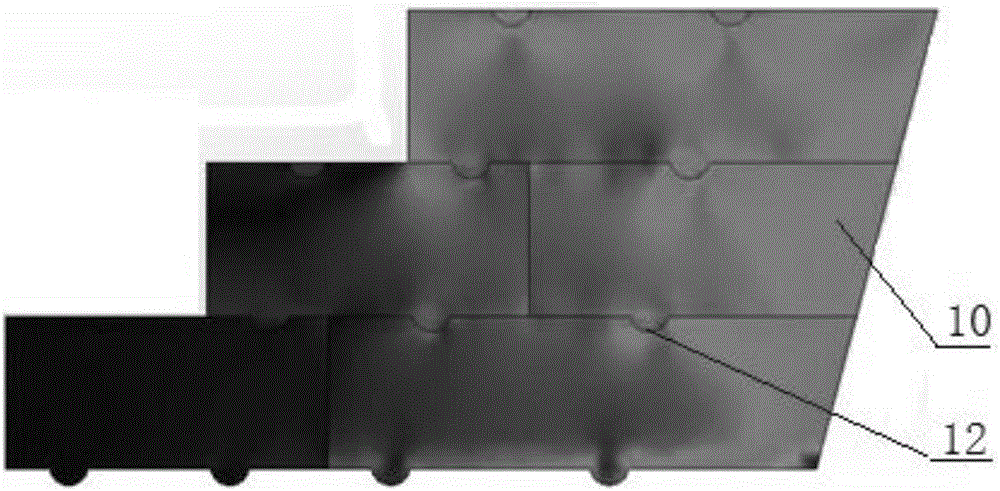

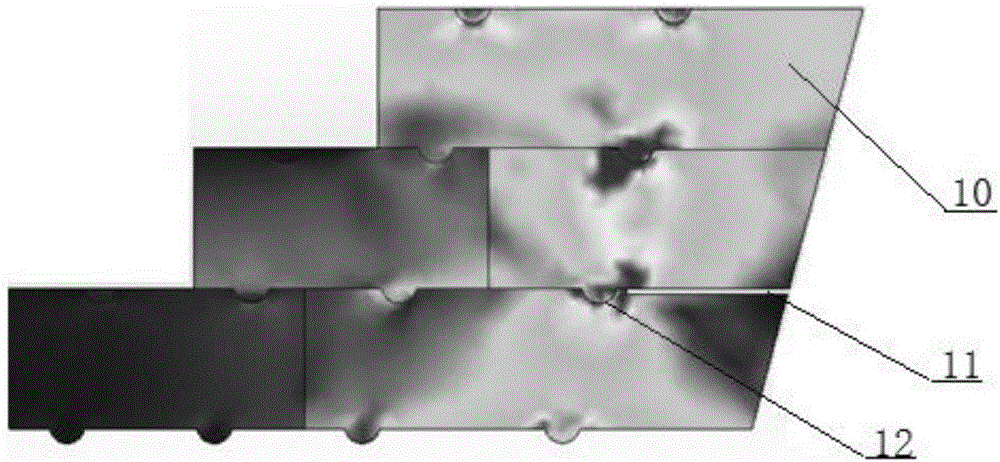

[0026] Such as image 3 As shown, a CDQ coke oven corbel structure according to the present invention includes a corbel column composed of masonry in the CDQ coke oven chute area, and the masonry includes corbel supporting bricks 1 and facing bricks 3 The facing brick 3 is a T-shaped structure, and the T-shaped facing brick 3 and the corbel supporting brick 1 on the corresponding side are built at intervals; An overall protective layer is formed on the outside.

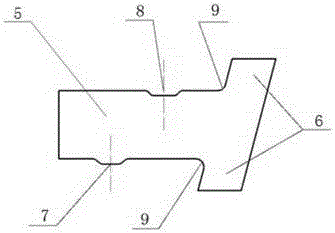

[0027] The T-shaped facing brick 3 is composed of a main body 5 and a wing plate 6 that is arranged at one end of the main body 5 and protrudes to both sides. The main body 5 is built horizontally, and the wing plate 6 is arranged obliquely. The outer side of the corbel support brick 1 that is built at intervals with the T-shaped facing brick 3 has a slope that matches the angle of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com