GGJ low-voltage reactive power compensation cabinet

A compensation cabinet, low-voltage technology, applied in substation/distribution device housing, fire rescue, etc., can solve the problems of damage to electronic devices, failure to extinguish fire in time, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

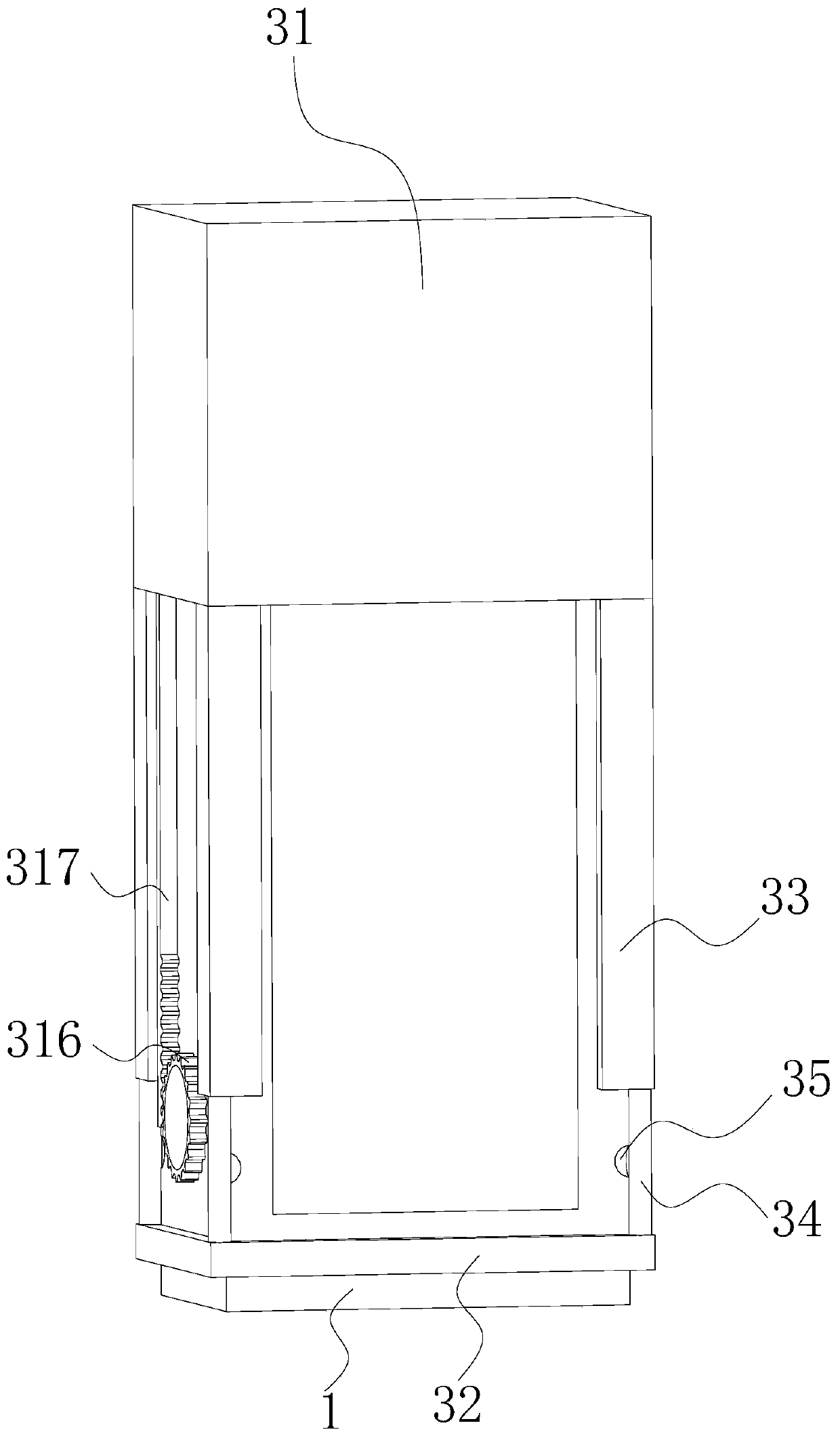

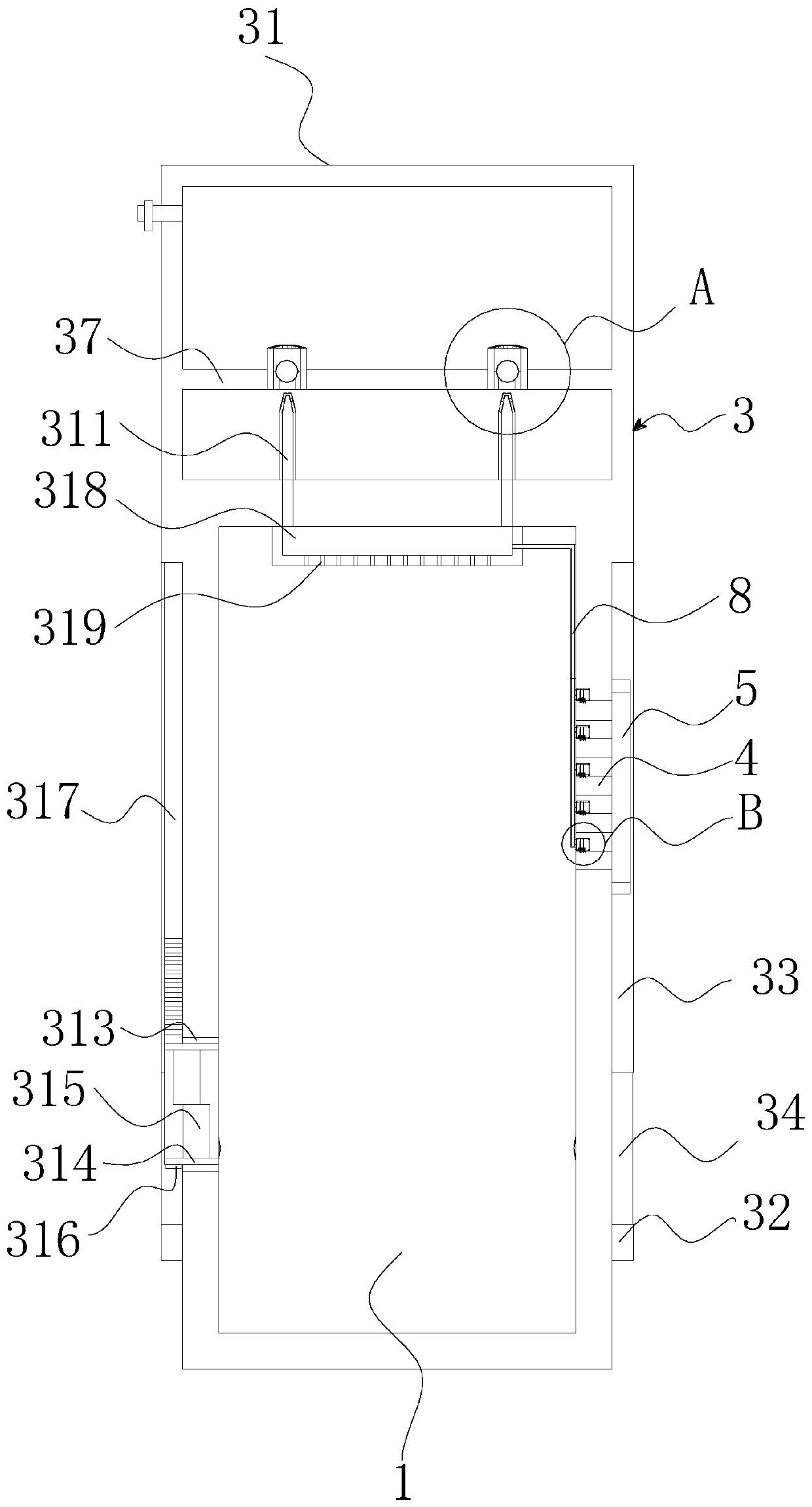

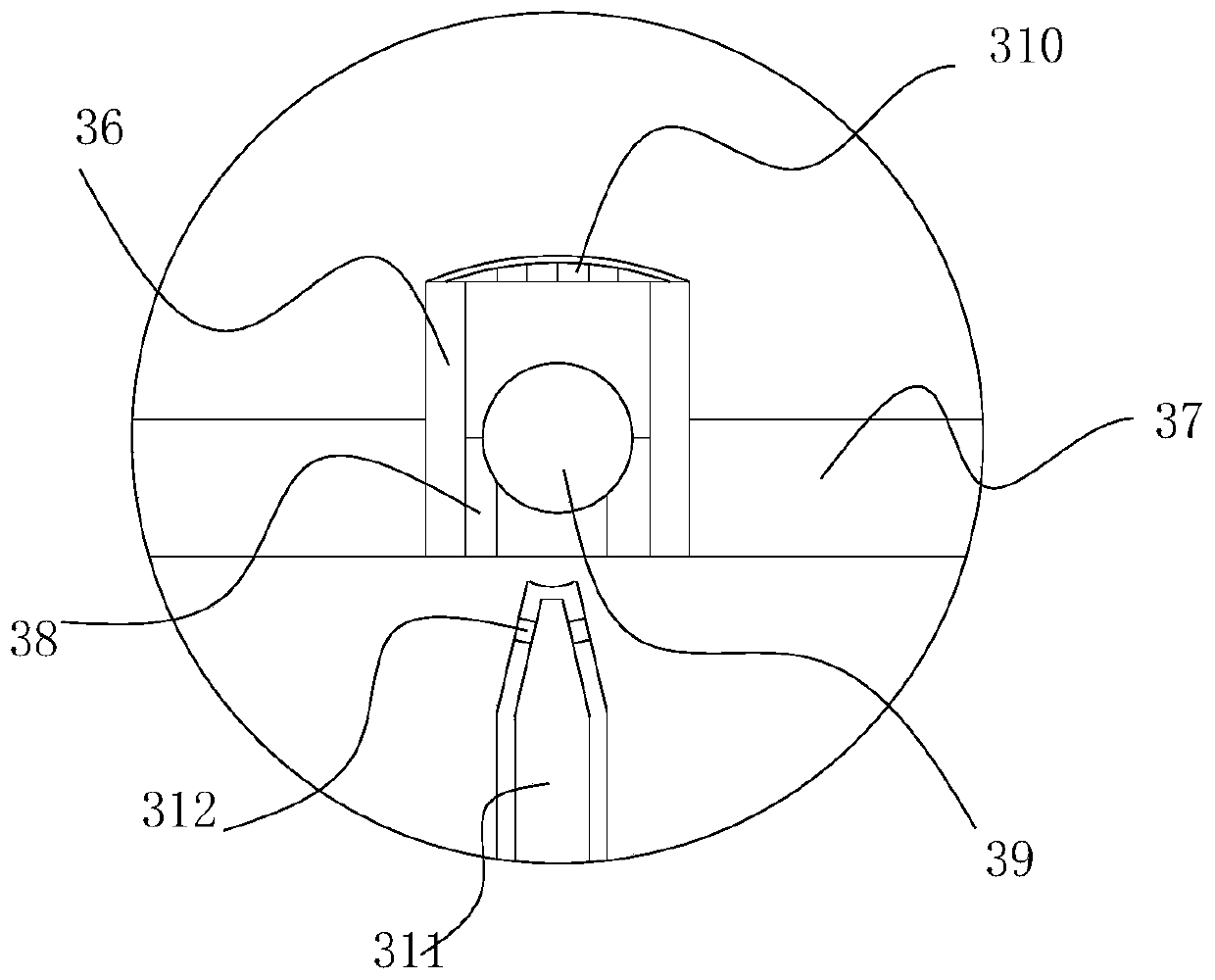

[0024] see Figure 1-4 , the present invention provides a technical solution: a GGJ low-voltage reactive power compensation cabinet, including a cabinet body 1, a feedback sealing air bag 2, a gas exchange fire extinguishing mechanism 3, the front of the cabinet body 1 is hinged with a cabinet door, and the right wall of the cabinet body 1 There are five strip-shaped heat dissipation holes 4 arranged in sequence from top to bottom on the upper side. A heat dissipation fan 5 is installed on the right side of the cabinet body 1 corresponding to the position of the strip-shaped heat dissipation holes 4. The feedback sealing airbag 2 is bonded to the strip-shaped heat dissipation In the gap inside the top wall of the hole 4 , the gas exchange fire extinguishing mechanism 3 is arranged outside the cabinet body 1 .

[0025] The feedback sealing airbag 2 is columnar, and the inner top wall and the inner bottom wall of the feedback sealing airbag 2 are bonded by the covering film 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com