Steamship provided with rollover self-rescuing system

A technology for ships and rollovers, which is applied in the directions of ship safety, ships, transportation and packaging, etc., can solve the problems that ships do not have structures and systems to prevent overturning, consume a lot of manpower and material resources, and cannot withstand the swivel nest.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

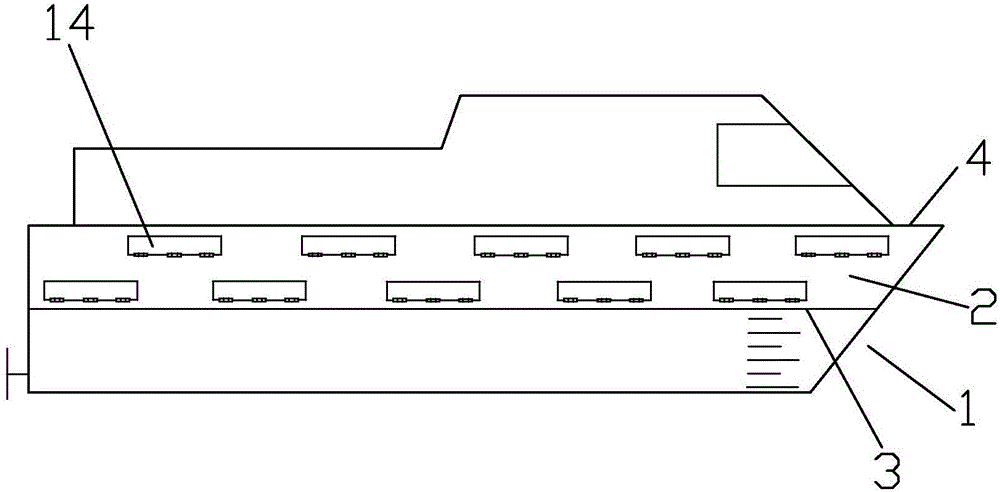

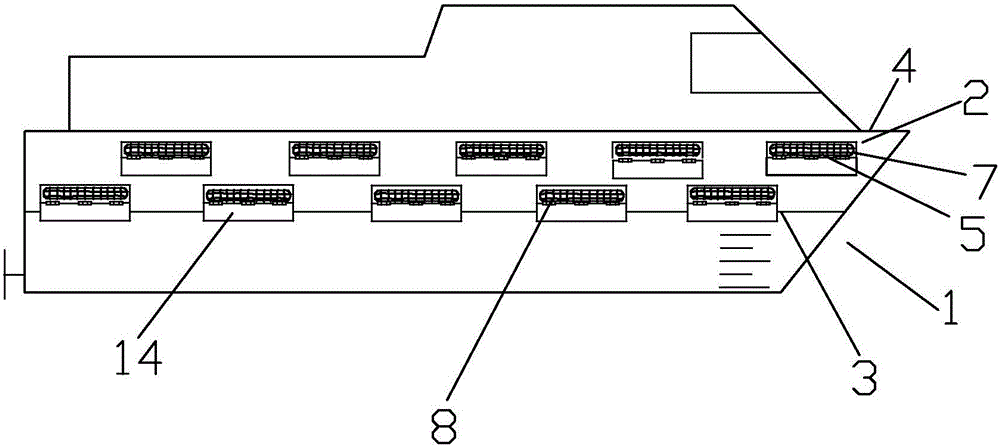

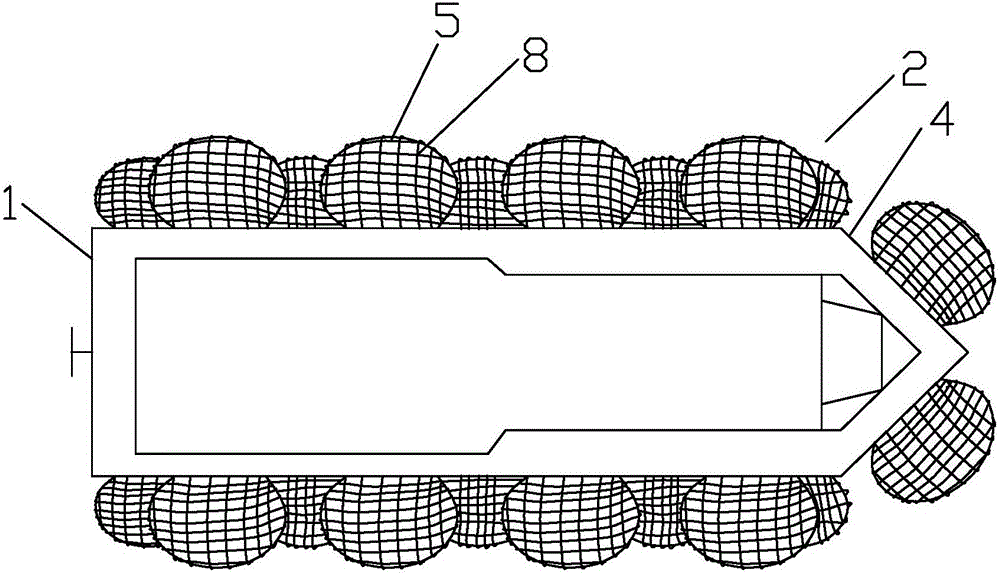

[0017] The following is figure 1 The embodiment represented by -4 further describes the present invention:

[0018] Including the ship 1, the ship 1 is equipped with a ship rollover self-rescue system 2, 20 airbags 5 arranged on both sides of the ship's side 4 above the waterline 3 of the ship, a hoist 6 for fixing and retracting the 20 airbags 5, and an airbag inflation system 7; the airbag 5 is fixedly connected to a stay rope 9 after covered by a nylon net 8, and the other end of the stay rope 9 is connected to the hoist 6, and the hoist 6 is arranged on the ship 1; the airbag is inflated System 7 is to be connected with high-pressure gas cylinder 12 by described airbag 5 through electronic valve 10 and pipeline 11; One can automatically control electronic valve 10, hoist 6 action automatic control system 13 and The electronic valve 10 and the hoist 6 are connected; the ship 1 is provided with a groove 14 for placing the air bag 5 when it is not inflated on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com