Temperature control system of semiconductor coating device

A technology of coating equipment and temperature control system, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of low heat conduction efficiency and achieve good heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

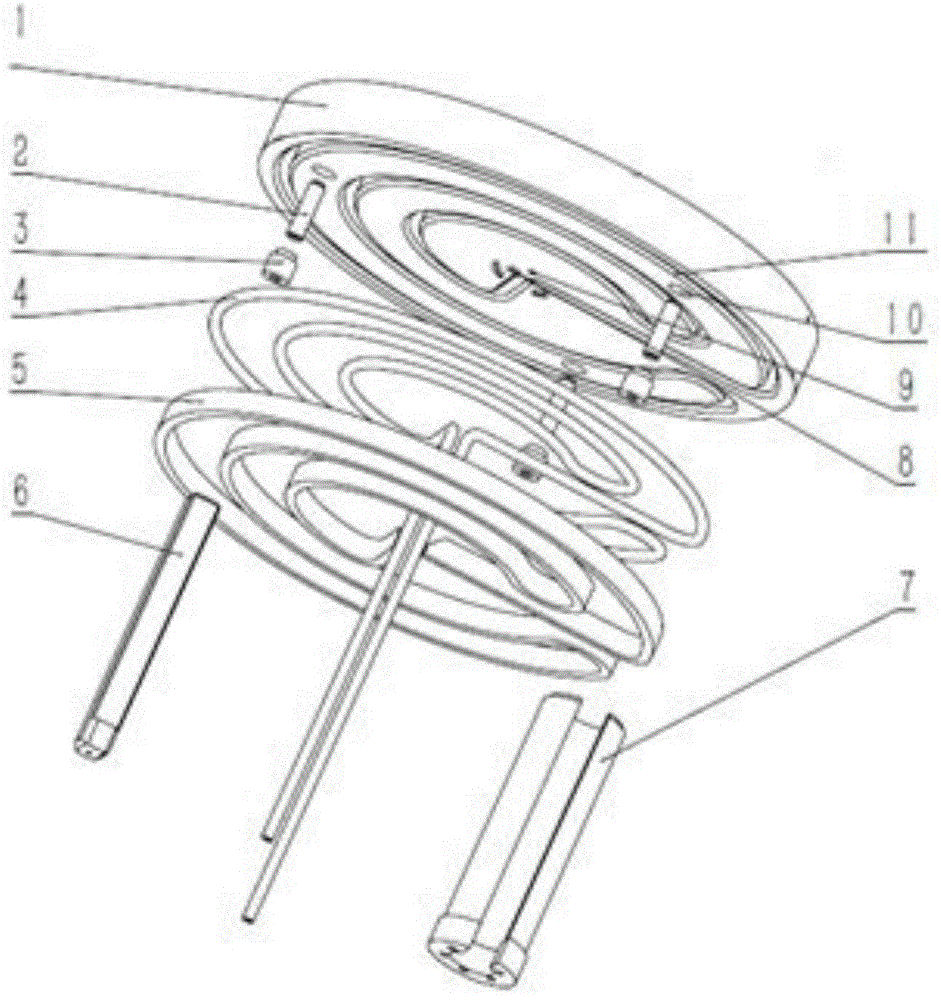

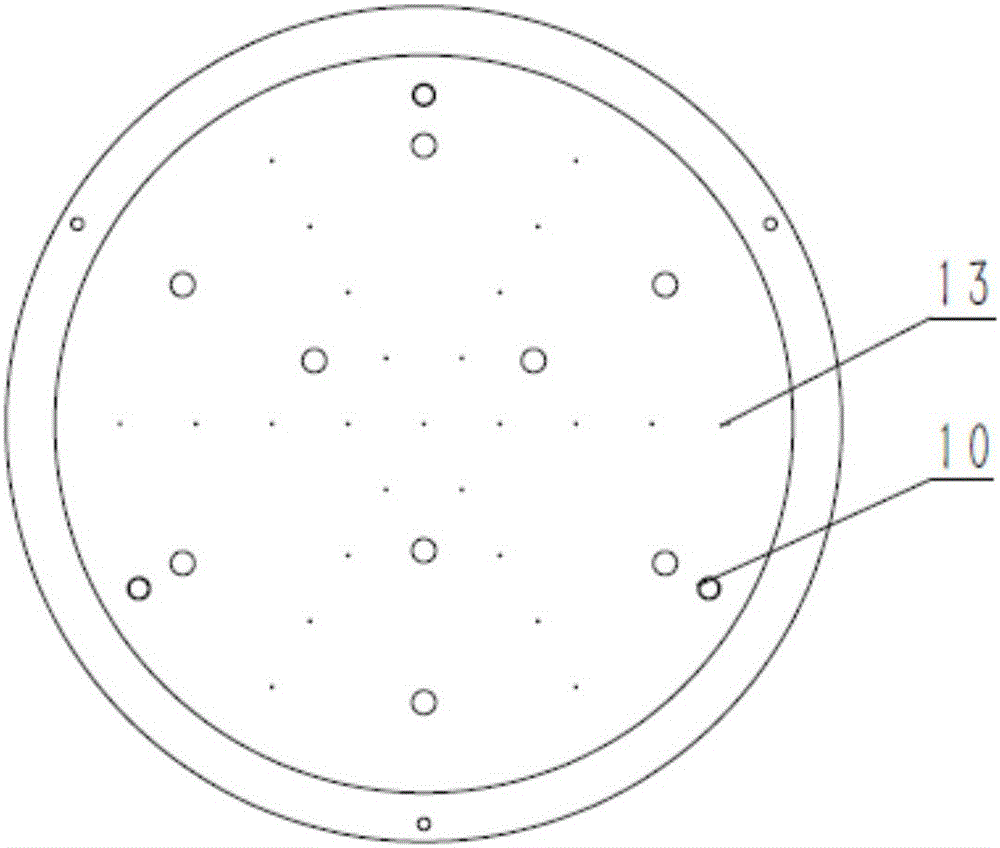

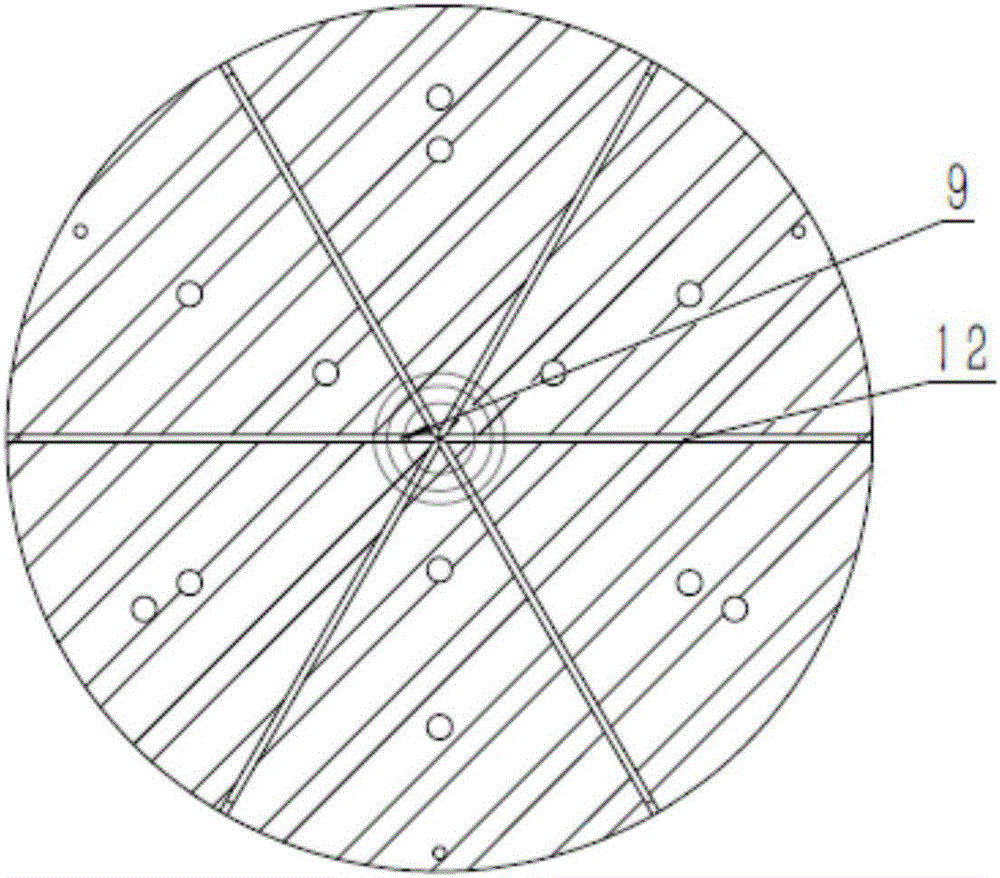

[0020] refer to Figure 1-4 , the temperature control system of semiconductor coating equipment, including a heating plate body 1, a heating plate medium pipeline groove 11 is opened on the lower surface of the heating plate body 1, the shape of the heating plate medium pipeline groove 11 matches the shape of the medium pipeline 4, Insert the medium pipe 4 into the medium pipe groove 11 of the heating plate, and then press the medium pipe pressing plate 5 with the same shape into the groove. The medium pipeline pressing plate 5 is fixedly connected with the heating tray body 1 . A thermocouple mounting hole 8 and a heat conduction gas inlet distribution hole 9 are formed at corresponding positions near the center of the lower plate surface of the heating plate body 1 . The above-mentioned thermocouple installation hole 8 is used to connect an external thermocouple, and the heat transfer gas inlet distribution hole 9 is connected to the heat transfer gas inlet pipe 6 as a gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com