Temperature control disc

A technology of warm plate and plate body, applied in the field of semiconductor thin film deposition application and manufacturing, can solve the problems of uneven wafer temperature, low heat exchange efficiency and productivity, and film failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

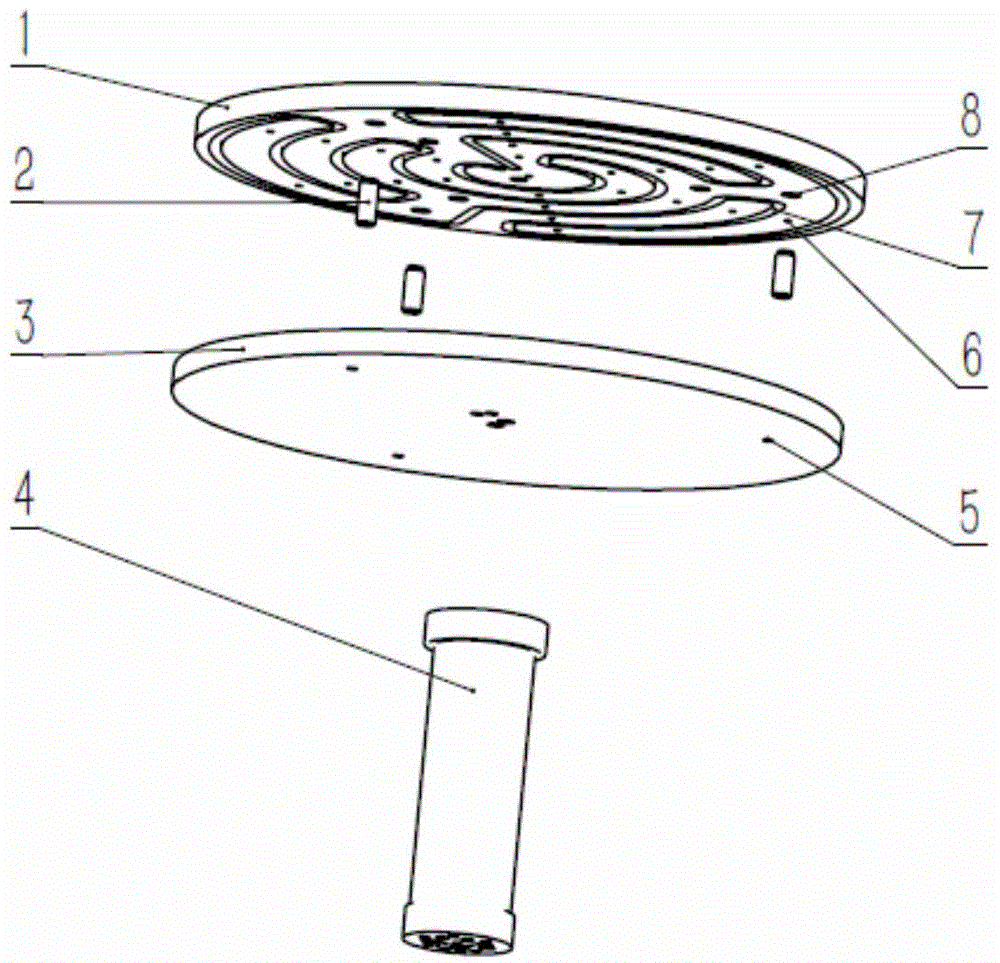

[0016] Such as Figure 1-4 As shown, the temperature control plate mainly includes three parts, namely: the upper plate body 1 of the heating plate, the lower plate body 3 of the heating plate and the base 4 of the heating plate.

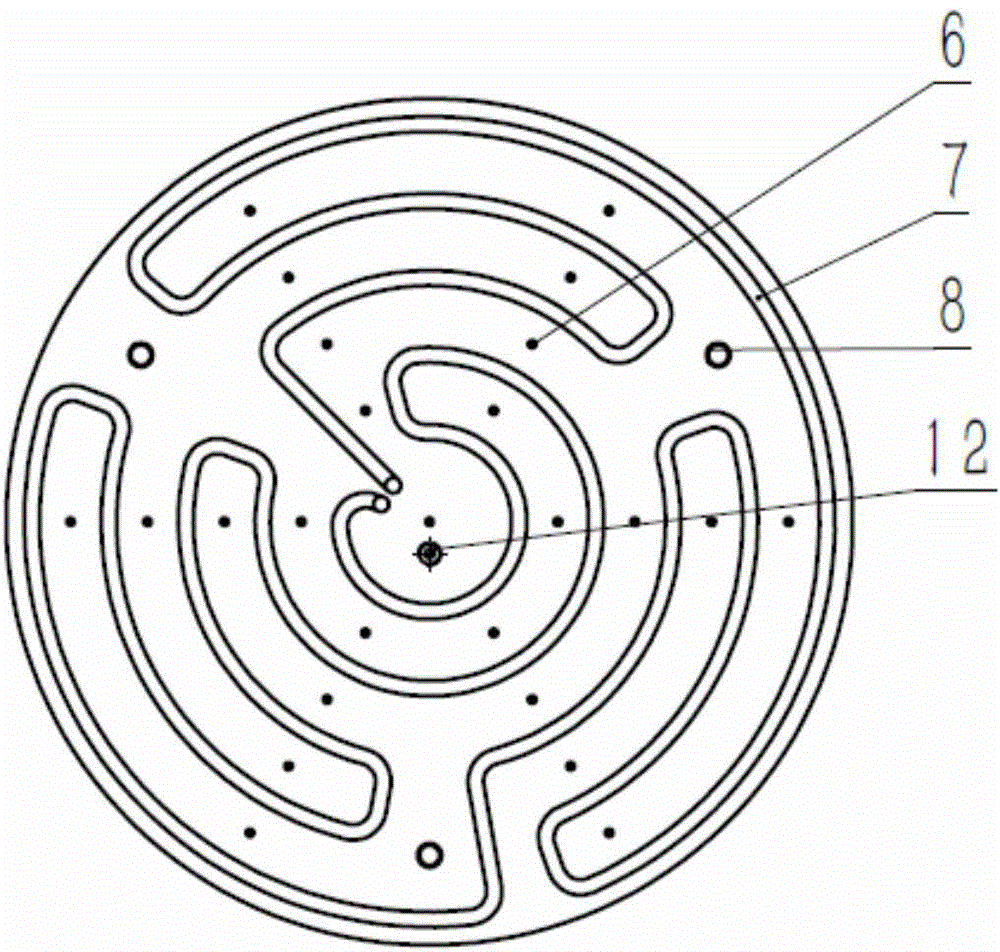

[0017] The lower surface of the upper plate body 1 of the heating plate has a medium channel hole 7 (the layout of the medium channel is as follows: figure 2 Shown); the lower surface of the upper plate body 1 of the heating plate is also provided with a heat conduction gas hole 6 and a thermocouple hole 12 distributed in the shape of rice; the lower surface of the upper plate body 1 of the heating plate is formed with a ceramic column hole 8 .

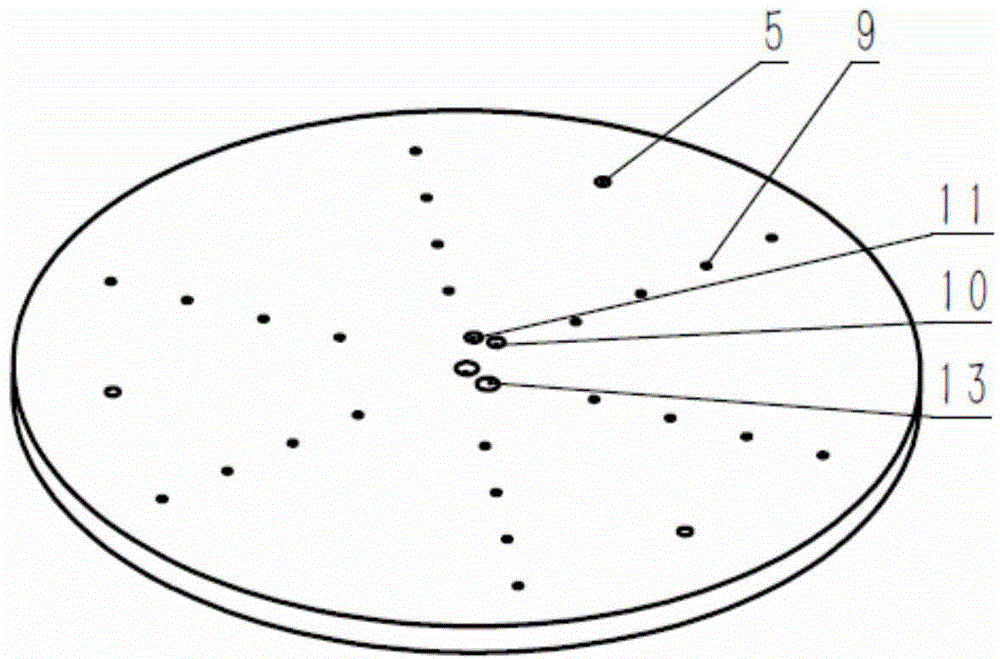

[0018] The lower plate body 3 of the heating plate is provided with a heat conduction gas distribution channel 14 for distributing the conduction gas. The cross-sectional view is shown in Figure 4 shown. There are heat conduction gas outlet holes 9 on the disk surface corresponding to the heat conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com