Extrusion feeding mechanism and extrusion injection molding machine

A technology of feeding mechanism and injection molding machine, which is applied in the field of extrusion injection molding machine, can solve the problem that the feeding stroke cannot meet the actual needs, and achieve the effect of speeding up the injection molding time, reducing the production cost and speeding up the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

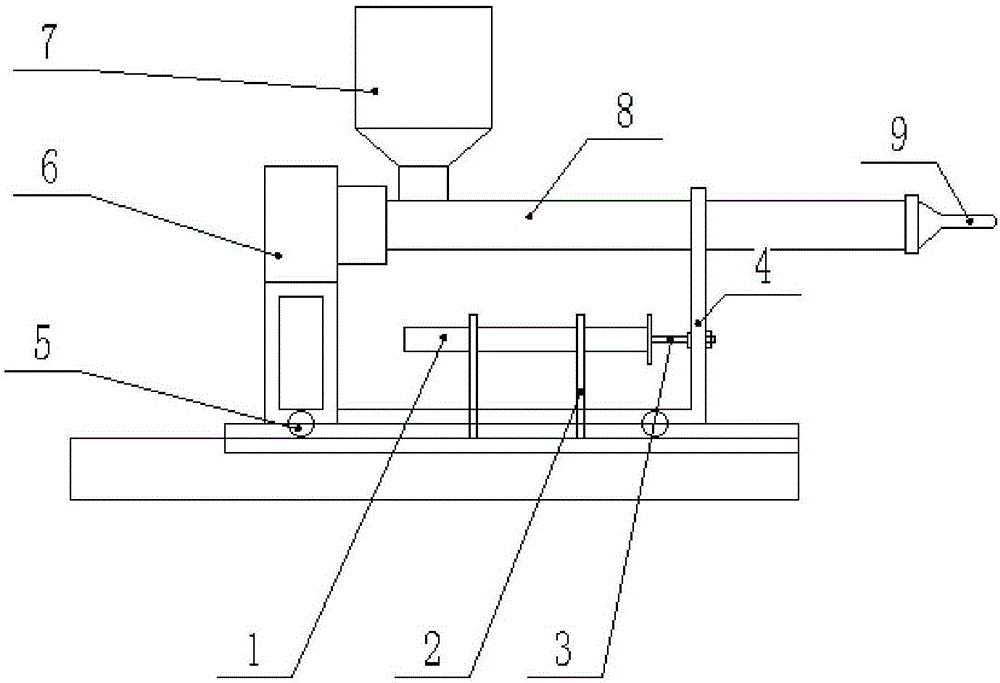

[0035] The specific implementation of the extrusion feeding mechanism provided by the present embodiment is as follows:

[0036] Such as figure 1 As shown, an extrusion feeding mechanism provided in this embodiment includes a propulsion component, a sliding component and an extrusion component, and the propulsion component drives the extrusion component to perform linear reciprocating motion through the sliding component;

[0037] The propulsion assembly includes a first support frame 2, a first oil cylinder 1 erected on the first support frame 2, and a connecting plate 4 capable of rectilinear reciprocating motion under the push of the first oil cylinder 1. The connecting plate 4 is provided with a The channel through which rack 2 passes;

[0038] The sliding assembly includes a base plate and a sliding part, and the first support frame 2 passes through the connecting plate 4 and is fixedly connected to the base plate;

[0039] The extruding assembly is provided with an ext...

Embodiment 2

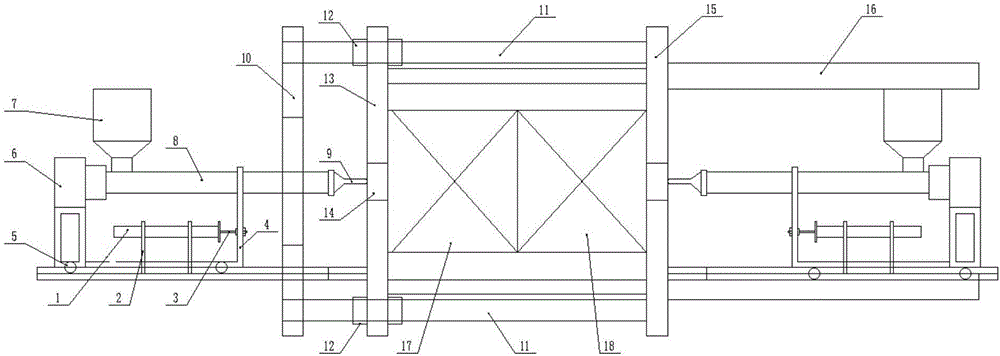

[0047] Such as figure 2 As shown, the extrusion injection molding machine provided in this embodiment includes the extrusion feeding mechanism of the above-mentioned embodiment 1. There are two extrusion feeding mechanisms, which are respectively arranged on both sides of the injection mold, and respectively correspond to the first An injection molding port 14 and a second injection molding port 19.

[0048] The optional technical solution of this embodiment is that the injection mold adopts a horizontal mold, and is provided with a moving mold body and a static mold body, a guiding device is arranged between the moving mold body and the static mold body, and the second oil cylinder 16 passes through the guiding device Drive the dynamic mold body to open the mold.

[0049] The optional technical solution of this embodiment is that the guide device includes a guide post 11, a guide sleeve 12 and a ball, and a point contact rolling interference fit is adopted between the guide...

Embodiment 3

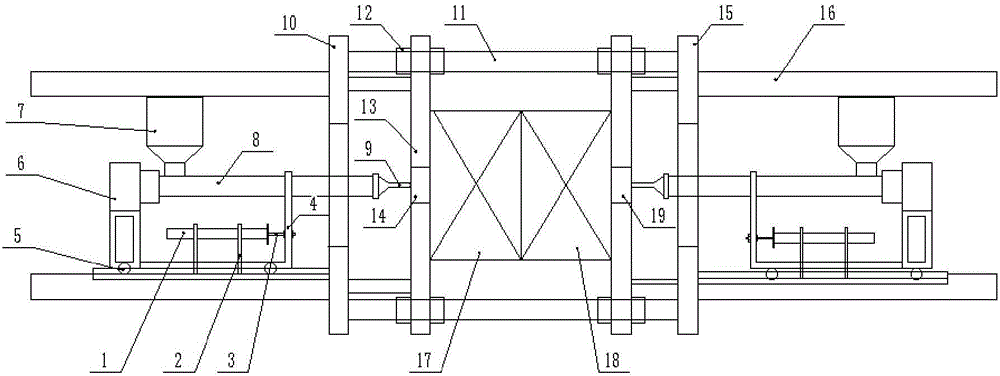

[0053] Such as image 3 As shown, the extrusion injection molding machine provided in this embodiment includes the extrusion feeding mechanism of the above-mentioned embodiment 1. There are two extrusion feeding mechanisms, which are respectively arranged on both sides of the injection mold, and respectively correspond to the first An injection port 14 and a second cavity 19 .

[0054] The optional technical solution of this embodiment is that the injection mold adopts a horizontal mold, and two movable mold bodies are provided, and a guide device is arranged between the two movable mold bodies, and the second fixed plate 16 drives the two movable mold bodies through the guide device. body mold.

[0055] The optional technical solution of this embodiment is that the guide device includes a guide post 11, a guide sleeve 12 and a ball, and a point contact rolling interference fit is adopted between the guide post 11, the guide sleeve 12 and the ball, and the guide post 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com