Flame retardant polyol composition and preparation method and application thereof

A flame-retardant polyol and composition technology, applied in the field of polyurethane foam, can solve the problems of complex preparation process, high flame-retardant cost, and general flame-retardant effect, and achieve good comprehensive performance, low oxygen index, and improved flame-retardant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The second embodiment of the present invention discloses the preparation method of the above-mentioned flame retardant polyol composition, which specifically includes the following steps:

[0074] Add epoxy-based substances into the reactor, and keep the reaction temperature in the reactor at 70-80°C;

[0075] Add phosphorus-containing small molecules dropwise, and the dropwise addition is completed after 0.5-1 hour. Raise the temperature of the reactor to 90°C and react for 3-5 hours;

[0076] Reduce the temperature of the reactor and discharge.

[0077] The third embodiment of the present invention discloses the application of the above-mentioned flame-retardant polyol composition or the flame-retardant polyol composition obtained by the above-mentioned preparation method in the preparation of polyurethane rigid foam.

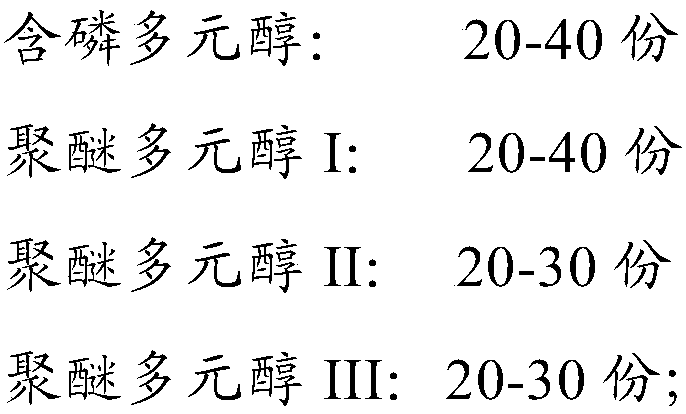

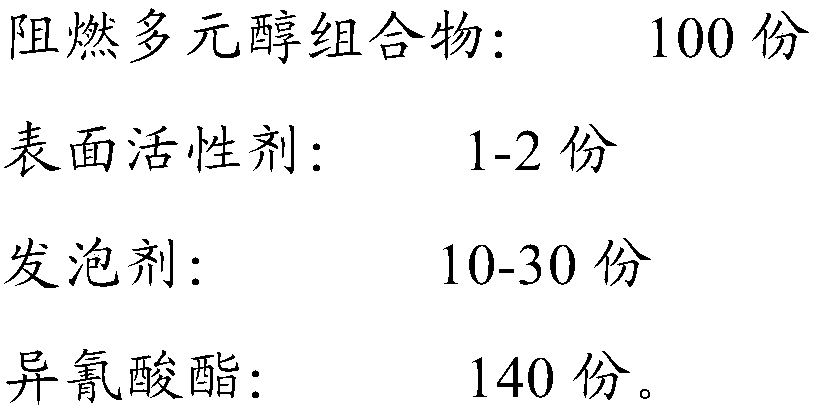

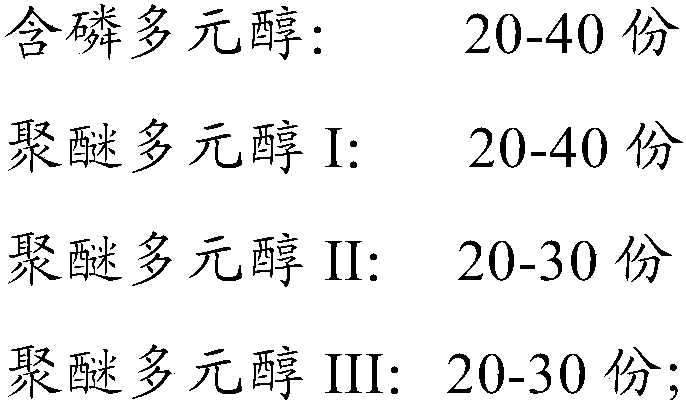

[0078] Wherein, the parts by weight of the raw materials of the above-mentioned polyurethane rigid foam plastics are as follows:

[0079]

[0080...

Embodiment 1

[0088] The phosphoric acid small molecule that the embodiment of the present invention selects is diethyl phosphate, the epoxy-based substance is epoxy resin E51, and molecular weight is polyethylene glycol glycidyl ether of 300;

[0089] The preparation method of the flame-retardant polyol is as follows: 380g of epoxy resin E51 and 300g of polyethylene glycol glycidyl ether are added to the reaction kettle, then the reaction temperature is raised to 70°C, and 600g of diethyl phosphate is added dropwise. After the hour dropwise addition was completed, the temperature was raised to 90° C., the reaction was carried out for 4 hours, and the temperature was lowered to discharge.

[0090] The prepared flame-retardant polyol has a viscosity of 1500-2000mpa.s and a hydroxyl value of 550-600mgKOH / g.

Embodiment 2

[0092] The phosphoric acid small molecule that the embodiment of the present invention selects is dibutyl phosphate, and the epoxy-based material is the polyethylene glycol glycidyl ether that epoxy resin E51, molecular weight are 200;

[0093] The preparation method of the flame-retardant polyol is as follows: 380g of epoxy resin E51 and 200g of polyethylene glycol glycidyl ether are added to the reaction kettle, then the reaction temperature is increased to 70°C, and 800g of diethyl phosphate is added dropwise. After the hour dropwise addition was completed, the temperature was raised to 90° C., the reaction was carried out for 4 hours, and the temperature was lowered to discharge.

[0094] The prepared flame-retardant polyol has a viscosity of 1300-1600mpa.s and a hydroxyl value of 530-550mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com