Reducing series-parallel connection channel plate type pulsating heat pipe

A pulsating heat pipe and parallel technology, applied in the field of heat transfer enhancement, can solve the problems of poor fluidity of the working medium, no lateral communication, and difficulty in eliminating radial temperature differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

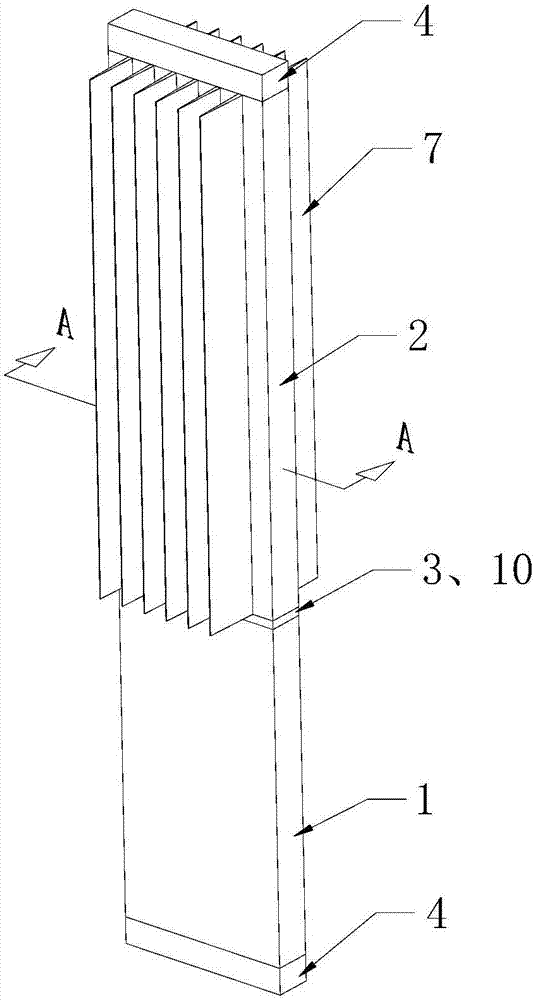

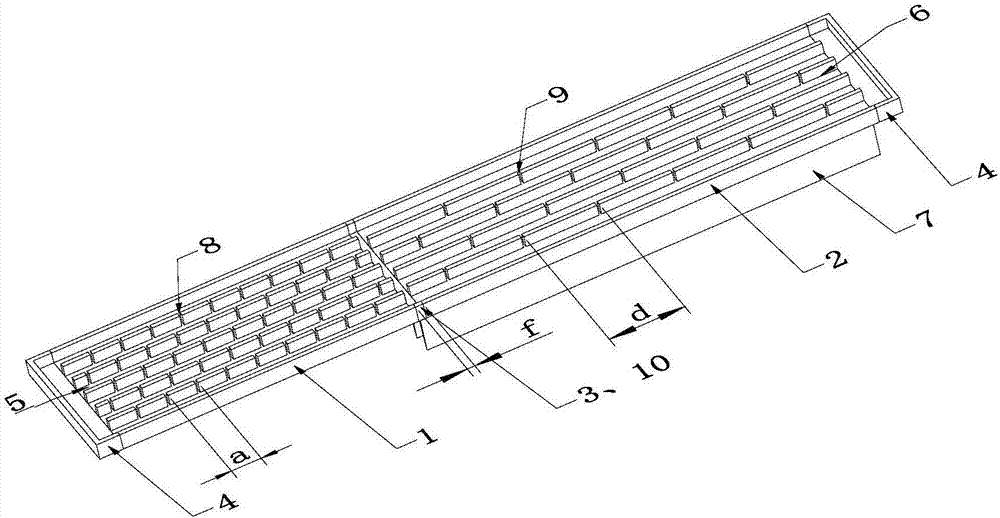

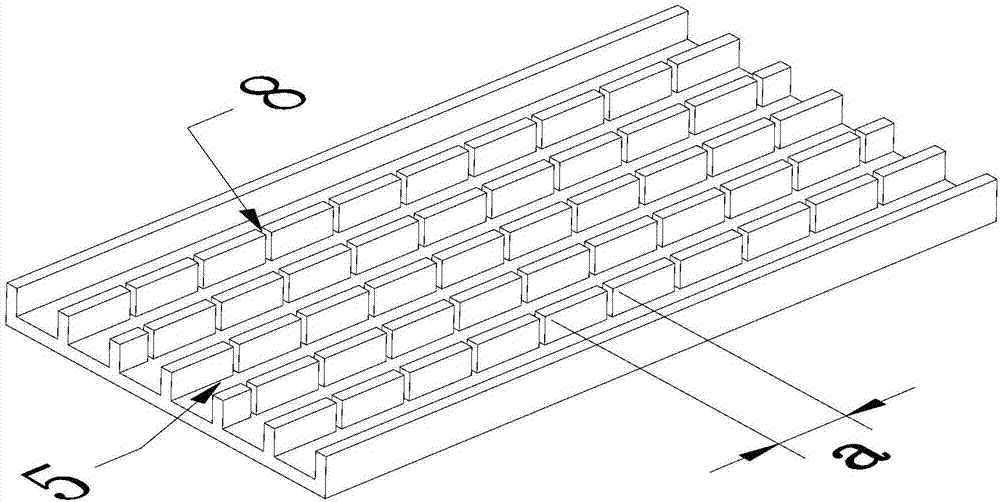

[0050] See attached figure 1 , 2 , 3, 4, 5, 6, the variable-diameter series and parallel channel plate type pulsating heat pipe includes one of the hot ends 1, one of the cold ends 2, and one of the type I intermediates 3, The two heads 4 are characterized in that: the hot end 1 is a rectangular flat plate with uniformly distributed equal-diameter hot-end channels 5 inside; the cold end 2 is a rectangular flat plate with uniformly distributed equal-diameter cold-end channels 6 inside; The equivalent diameter of the channel 6 at the cold end is 2.67 times the equivalent diameter of the channel 5 at the hot end; the hot end 1 and the cold end 2 are connected through the intermediate body 3 .

[0051] A balance hole 8 is provided on the partition wall of the adjacent hot end channel 5 in the hot end 1 , and a balance hole 9 is provided on the partition wall of the adjacent cold end channel 6 in the cold end 2 .

[0052] One end of the hot end 1 is connected to the intermediate ...

Embodiment 2

[0068] See attached image 3 , 4 , 6, 7, 8, the variable-diameter series and parallel channel plate type pulsating heat pipes include 1 of the hot ends 1, 2 of the cold ends 2, 1 of the type II intermediates 3, 3 The head 4 is characterized in that: the hot end 1 is a rectangular flat plate with uniformly distributed equal-diameter hot-end channels 5; the cold end 2 is a rectangular flat plate with uniformly distributed equal-diameter cold-end channels 6; The equivalent diameter of the channel 6 at the cold end is 1.67 times the equivalent diameter of the channel 5 at the hot end; the hot end 1 and the cold end 2 are connected through the intermediate body 3 .

[0069] A balance hole 8 is provided on the partition wall of the adjacent hot end channel 5 in the hot end 1 , and a balance hole 9 is provided on the partition wall of the adjacent cold end channel 6 in the cold end 2 .

[0070] One end of the hot end 1 is connected to the intermediate body 3, and the other end is p...

Embodiment 3

[0086] See attached image 3 , 4 , 6, 9, 10, the variable-diameter series, parallel channel plate type pulsating heat pipe includes 1 of the hot end 1, 3 of the cold end 2, 1 of the III-type intermediate 3, 4 The head 4 is characterized in that: the hot end 1 is a rectangular flat plate with uniformly distributed equal-diameter hot-end channels 5; the cold end 2 is a rectangular flat plate with uniformly distributed equal-diameter cold-end channels 6; The equivalent diameter of the channel 6 at the cold end is 1.13 times the equivalent diameter of the channel 5 at the hot end; the hot end 1 and the cold end 2 are connected through the intermediate body 3 .

[0087] A balance hole 8 is provided on the partition wall of the adjacent hot end channel 5 in the hot end 1 , and a balance hole 9 is provided on the partition wall of the adjacent cold end channel 6 in the cold end 2 .

[0088] One end of the hot end 1 is connected to the intermediate body 3, and the other end is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com