A tire mold casting device

A technology of tire molds and metal molds, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve the problems of high tire mold manufacturing costs, easy shrinkage, poor heat dissipation of gypsum, etc., and achieve mold quality assurance, The effect of prolonging the service life and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

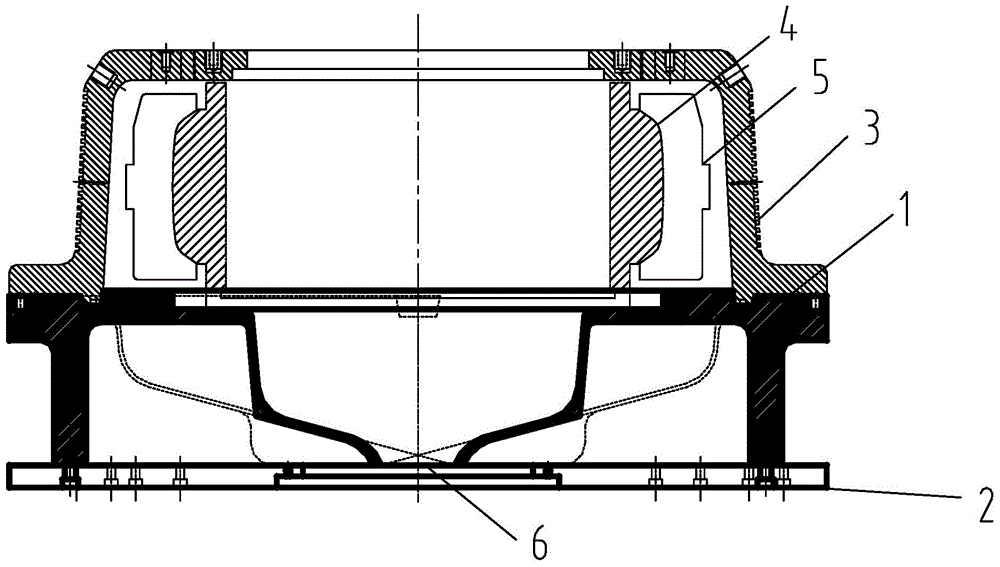

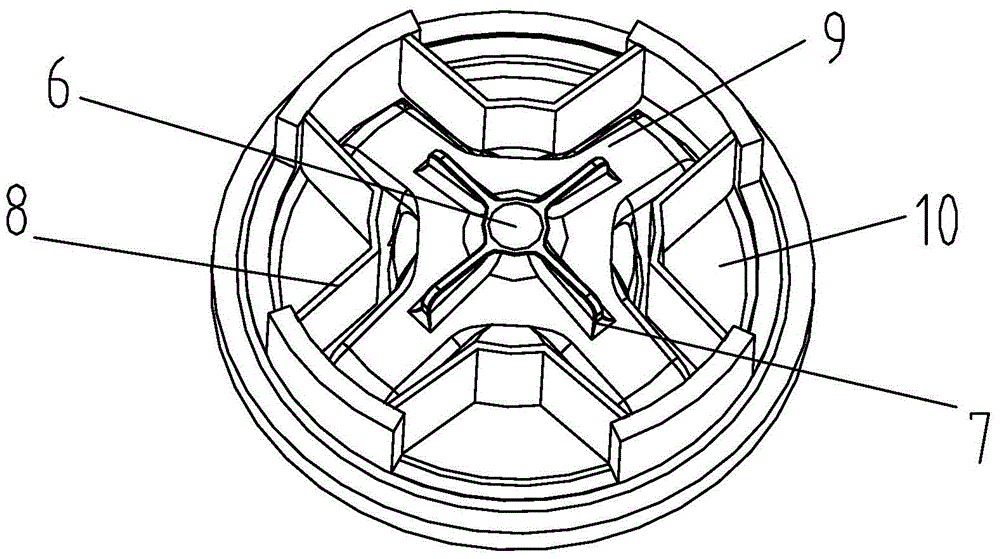

[0014] Such as figure 1 , the present invention comprises soup channel 1, soup channel bottom plate 2, metal mold 3, gypsum type 4, casting mold 5, runner opening 6, reinforcing rib 7, dividing rib 8, heat preservation zone 9 and heat dissipation zone 10, wherein metal mold 3 is positioned at In the outermost layer, the metal mold 3 is provided with a casting mold 5 and a plaster mold 4, a runner opening 6 is arranged in the middle of the soup channel base plate 2, and a circle of dividing ribs 8 is arranged on the soup channel base plate 2, and the dividing ribs 8 connect the back side of the soup channel 1 Divided into heat preservation area 9 and heat dissipation area 10, the heat preservation area 9 on the back of the soup channel corresponds to the inner cavity of the soup channel front, the heat preservation area 9 is located on the inner side of the dividing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com